Device capable of rotating workpieces conveyed by production line 90 degrees

A production line and workpiece technology, which is applied to the field of devices where the workpiece rotates 90 degrees, can solve the problems of large production line area, easy failure of production line, long transfer time of sand box, etc. , to avoid the effect of excessive rotation of the swing arm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

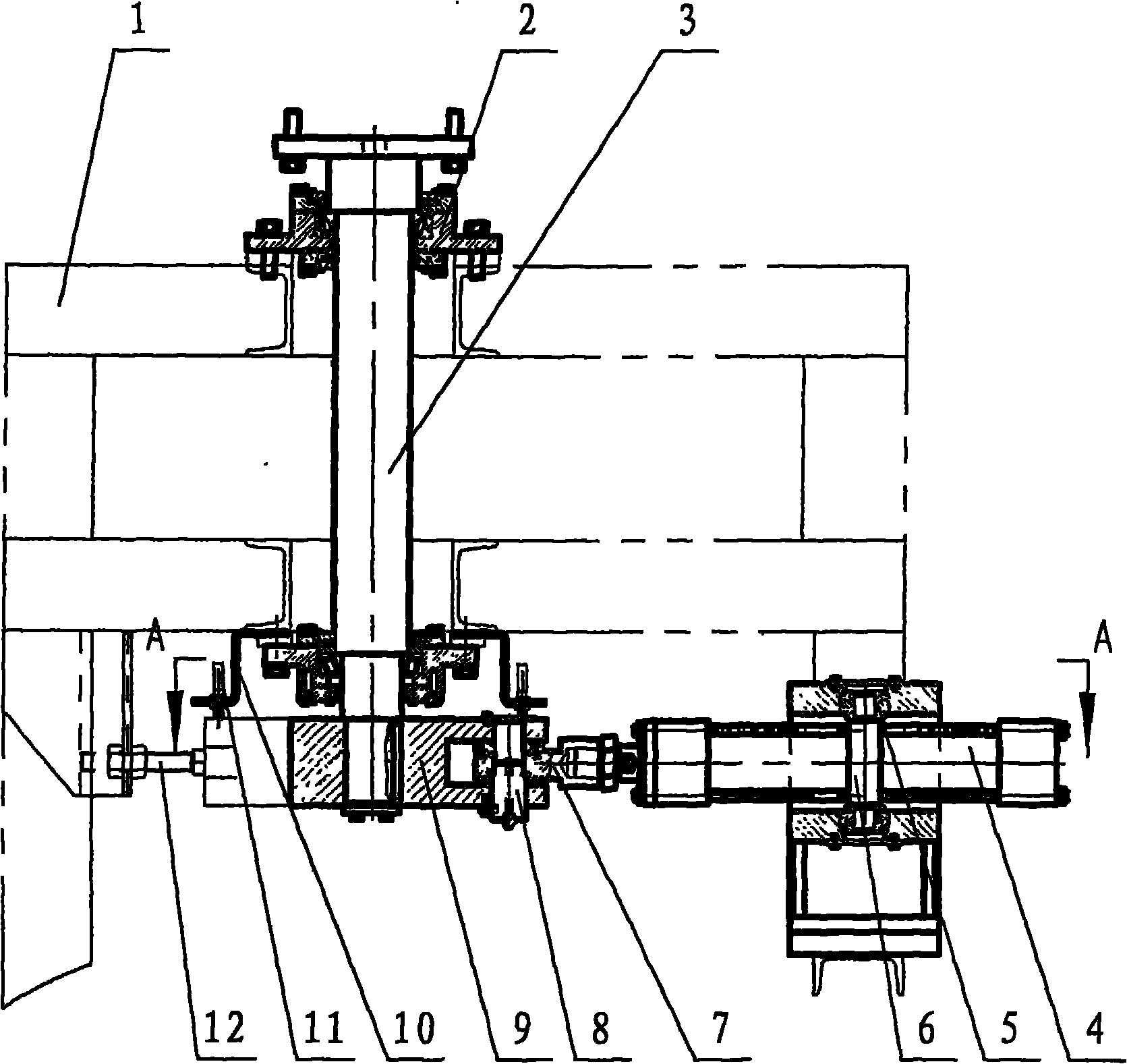

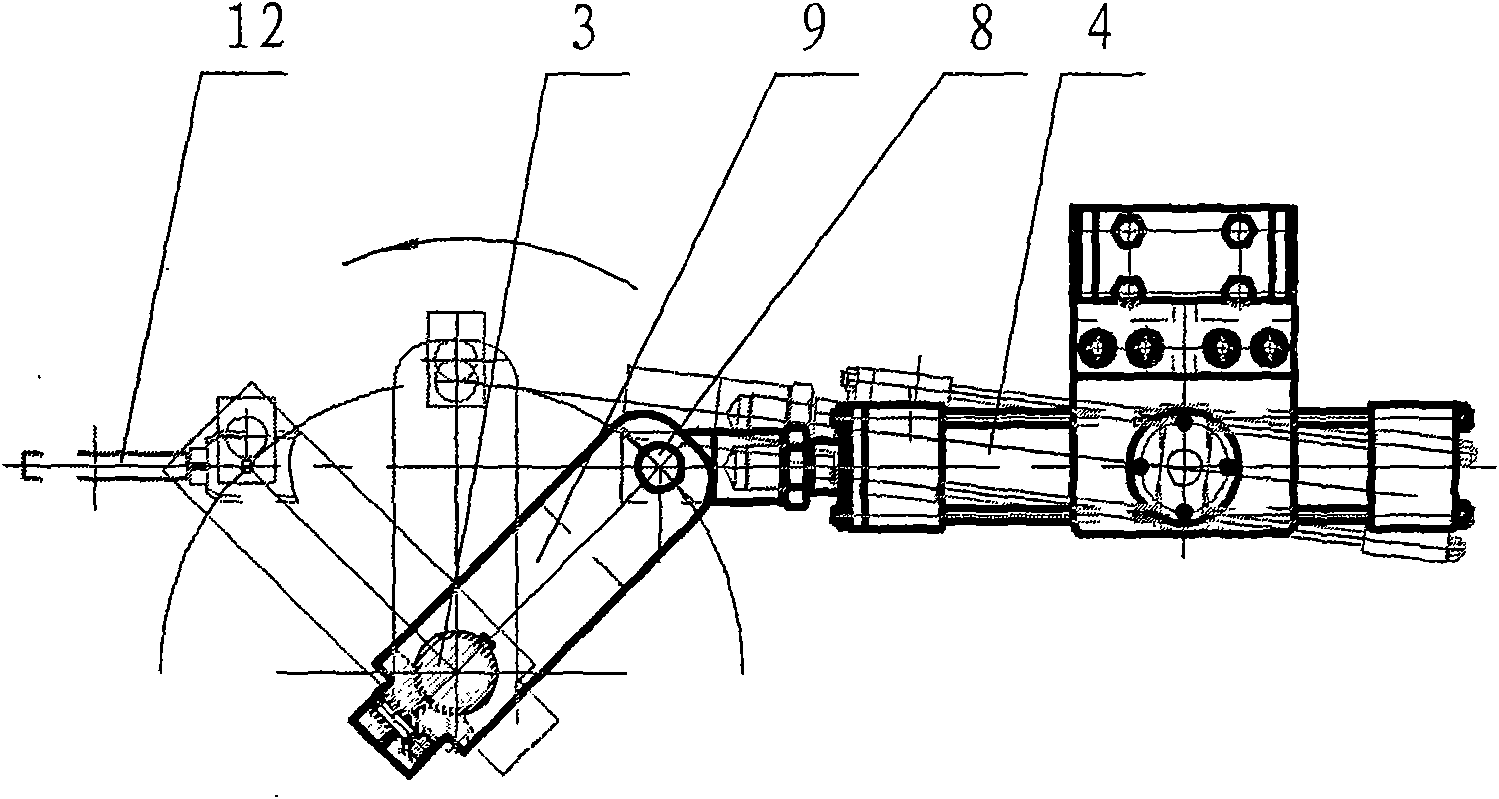

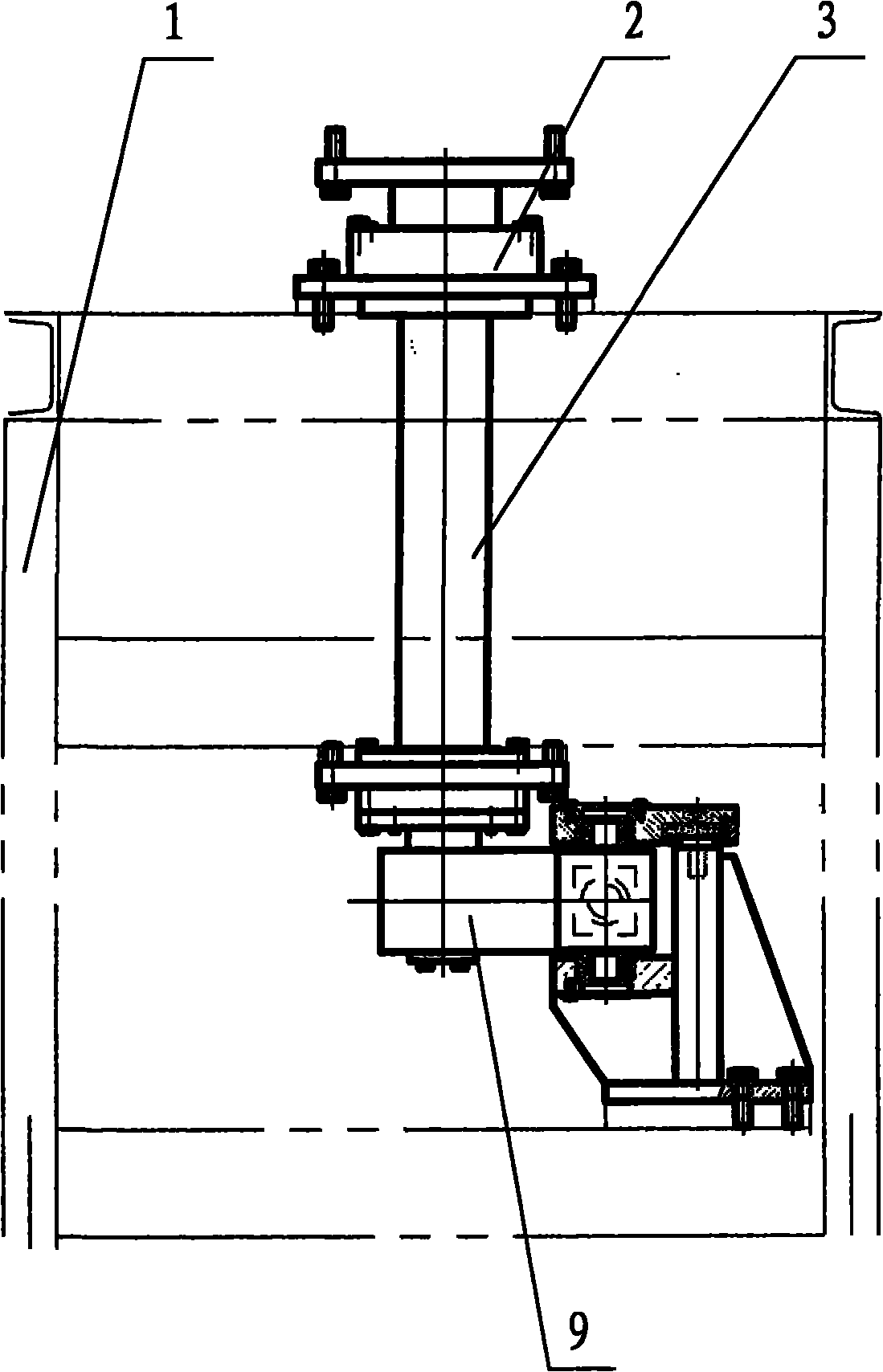

[0019] A device that can rotate workpieces conveyed by the production line by 90 degrees, including a hydraulic cylinder 4, which is horizontally hinged on the frame 1 of the production line through a rotating shaft 6 and a self-lubricating radial joint bearing 5, so that the hydraulic cylinder can be used in Swing within a smaller range.

[0020] The plunger rod 7 of the hydraulic cylinder is hinged to one end of a horizontal swing arm 9 through a rotating shaft 8, and the other end of the swing arm is fixed to a rotating vertical shaft 3, which is vertical to the production line. Bearing block 2 is installed on the frame of production line. The upper end of the rotating vertical shaft is fixed with a roller table (not shown in the figure)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com