Connection fitting of family product

A technology for connecting accessories and household products, which is applied in the direction of furniture connection, connecting components, mechanical equipment, etc. Potential safety hazards, quick connections, and improved construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

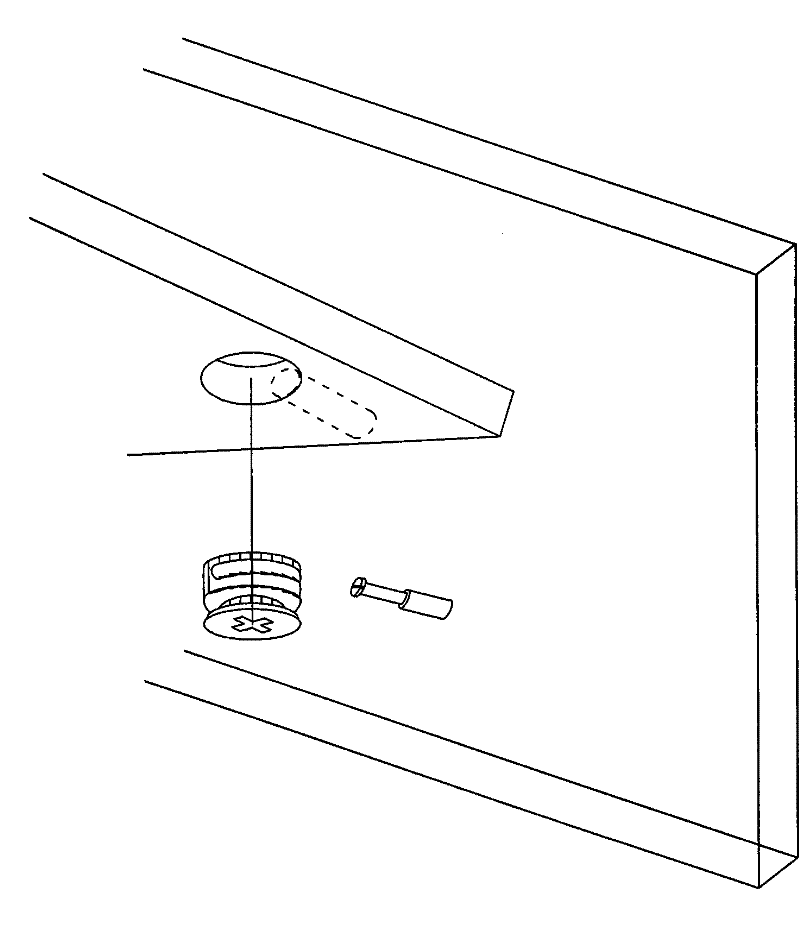

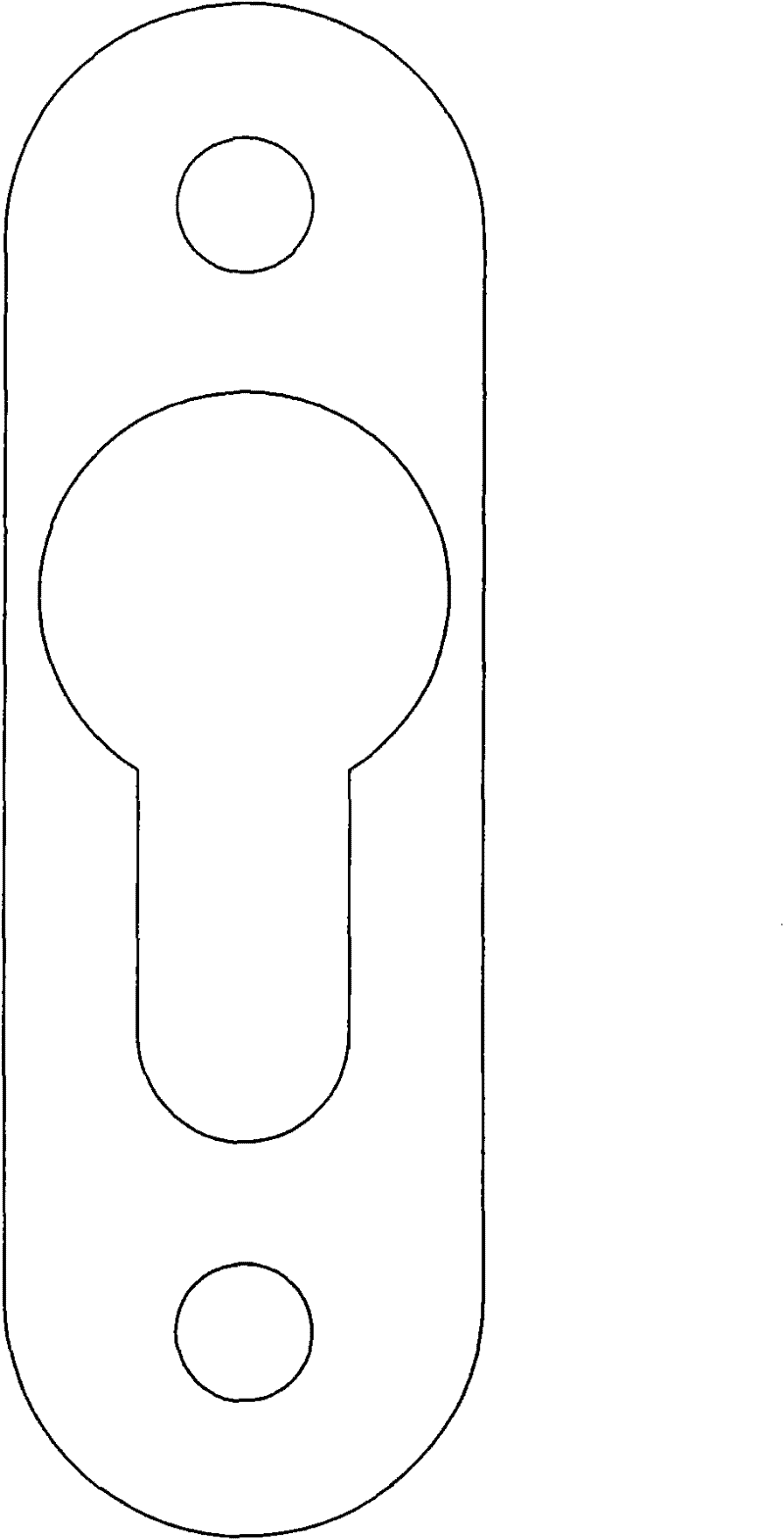

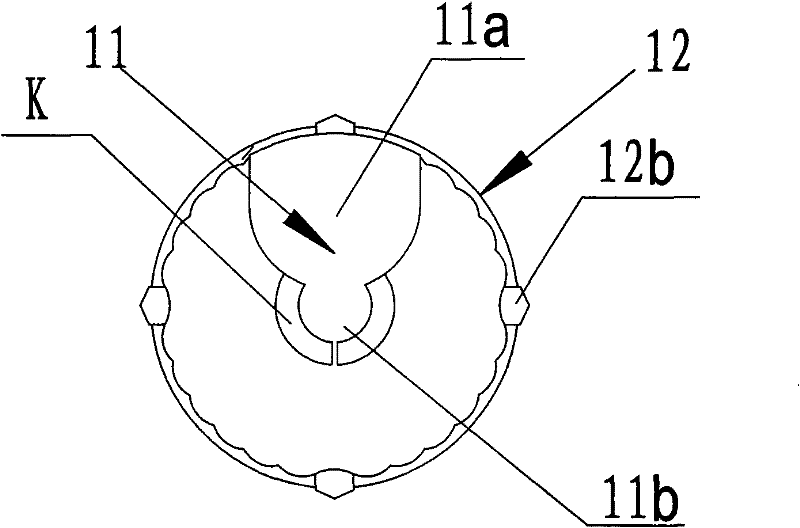

[0062] when using as Figure 12 , Figure 13 For the cap screw 2 shown in , the axial outer surface of the accessory body 1 is a toothed surface 12, and the positioning section 21 of the screw 2 includes a screw head 21a and a screw shaft 21b; the special-shaped groove 11 on the accessory body 1 by such as Figure 3-6 The shown opening groove 11a is combined with a circular positioning groove 11b, and the positioning groove 11b is integrally connected with the opening groove 11a. The screw head 21 a and the screw shaft 21 b on the screw positioning section 21 can enter through the opening groove 11 a, and are positioned and connected in the circular positioning groove 11 b on the accessory body 1 . When dismounting, the positioning section 21 of the screw is still withdrawn from the opening groove 11a.

[0063] At least one notch that can be opened and closed appropriately as shown in the figure can be provided on the circular positioning groove 11b, which is conducive to t...

Embodiment 2

[0066] when using as Figure 11 For the headless screw 2 shown, the axial outer surface of the accessory body 1 is a toothed surface 12, and the positioning section 21 of the screw 2 only includes the screw rod 21b; the special-shaped groove 11 on the accessory body 1 also includes the following Figure 3-6 The shown integrally connected opening groove 11a and a circular positioning groove 11b for positioning connection, the screw rod 21b enters or exits from the opening groove 11a;

[0067] Similarly, at least one notch that can be properly opened and closed can be provided on the circular positioning groove 11b, which is conducive to the expansion of the accessory body 1 along its radial direction; the center of the circular groove 11b coincides with the center of the accessory body 1, which is convenient for assembly quick positioning.

[0068] The setting of the screw connection section 22 is the same as that in Embodiment 1.

Embodiment 3

[0070] when using as Figure 7 or Figure 8 In the case of the accessory body 1 shown, its axial outer surface is a toothed surface 12, and the positioning section 21 of the screw 2 only includes the screw rod 21b;

[0071] The special-shaped groove 11 on the accessory body 1 is only a circular positioning groove 11 b for positioning and connection, and the circular positioning groove 11 b is centrally arranged on the top surface of the accessory body 1 . Once it needs to be disassembled, the positioning section 21 of the screw 2 can be rotated out of the circular positioning groove 11b.

[0072] The setting of the screw connection section 22 can also be the same as that in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com