LED flat panel display unit with drive control and production method thereof

A drive control, flat panel display technology, applied in electrical components, static indicators, instruments, etc., can solve the problems of inability to meet the requirements of LED panels, insufficient LCD color reproduction, and long LCD response time, achieving extremely high pixel pitch and low cost. , the effect of good control performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

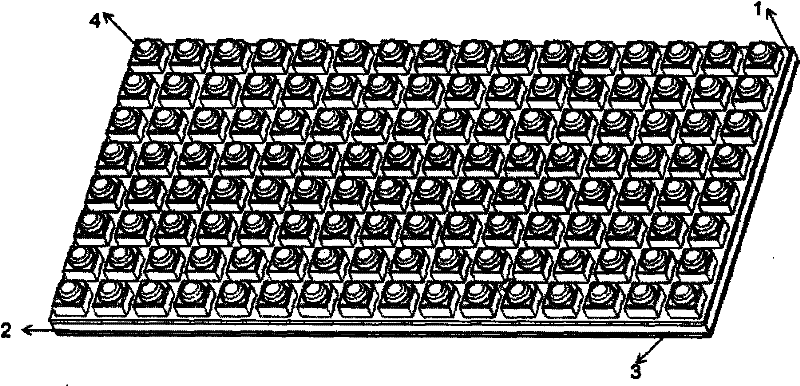

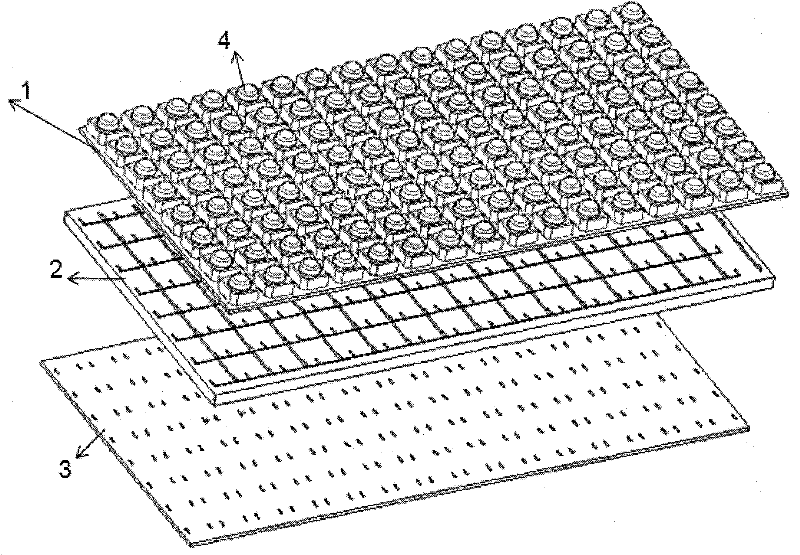

[0039] Such as figure 1 and 2As shown, the LED display device is composed of a top-layer insulating circuit substrate 1, a middle-layer insulating circuit substrate 2 and a bottom-layer insulating circuit substrate 3, and the three-layer insulating circuit substrates are sequentially laminated at high temperature to form a whole; LED crystal grains 4 are arranged in a matrix on the top insulating circuit The upper surface of the substrate 1; a plurality of scanning circuit lines L and a plurality of data circuit lines D are arranged on the middle insulating circuit substrate 2, so as to control the lighting and extinguishing of the LED grain 4; a plurality of A constant current control circuit is used to supply power to the LED crystal grains, and multiple scanning circuit line control chips and multiple data circuit line control chips are used to control multiple scanning circuit lines L and multiple data circuit lines D.

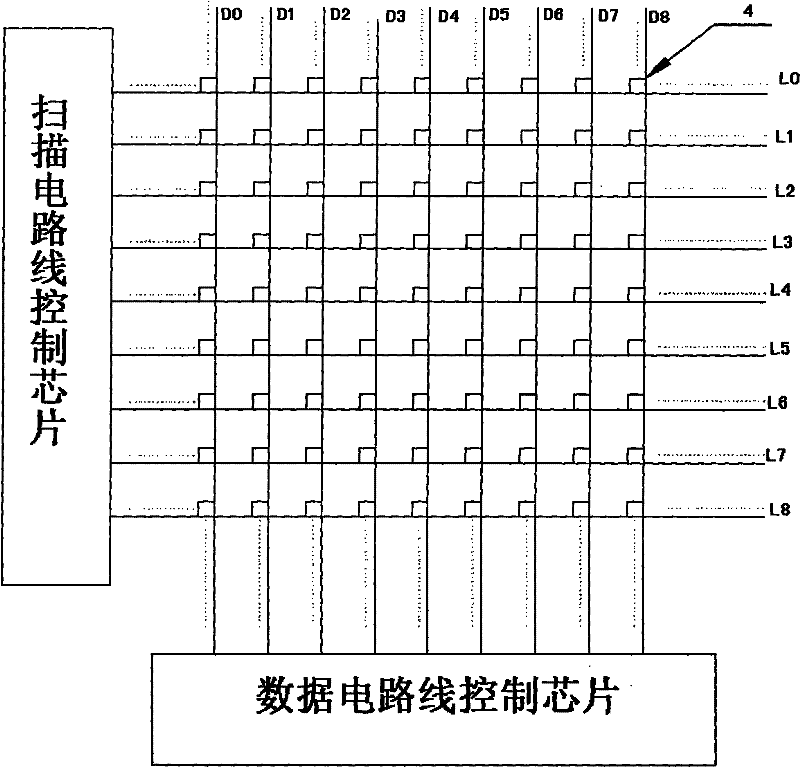

[0040] Such as image 3 A plurality of scanning ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com