Cathode, membrane electrode comprising the same, and preparation method thereof

A cathode and anode technology, applied in battery electrodes, alkaline battery electrodes, circuits, etc., can solve the problems of easy agglomeration of polymer electrolytes, unstable catalysts, and small catalyst contact area, and achieve improved contact area, catalytic activity and stability. High performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

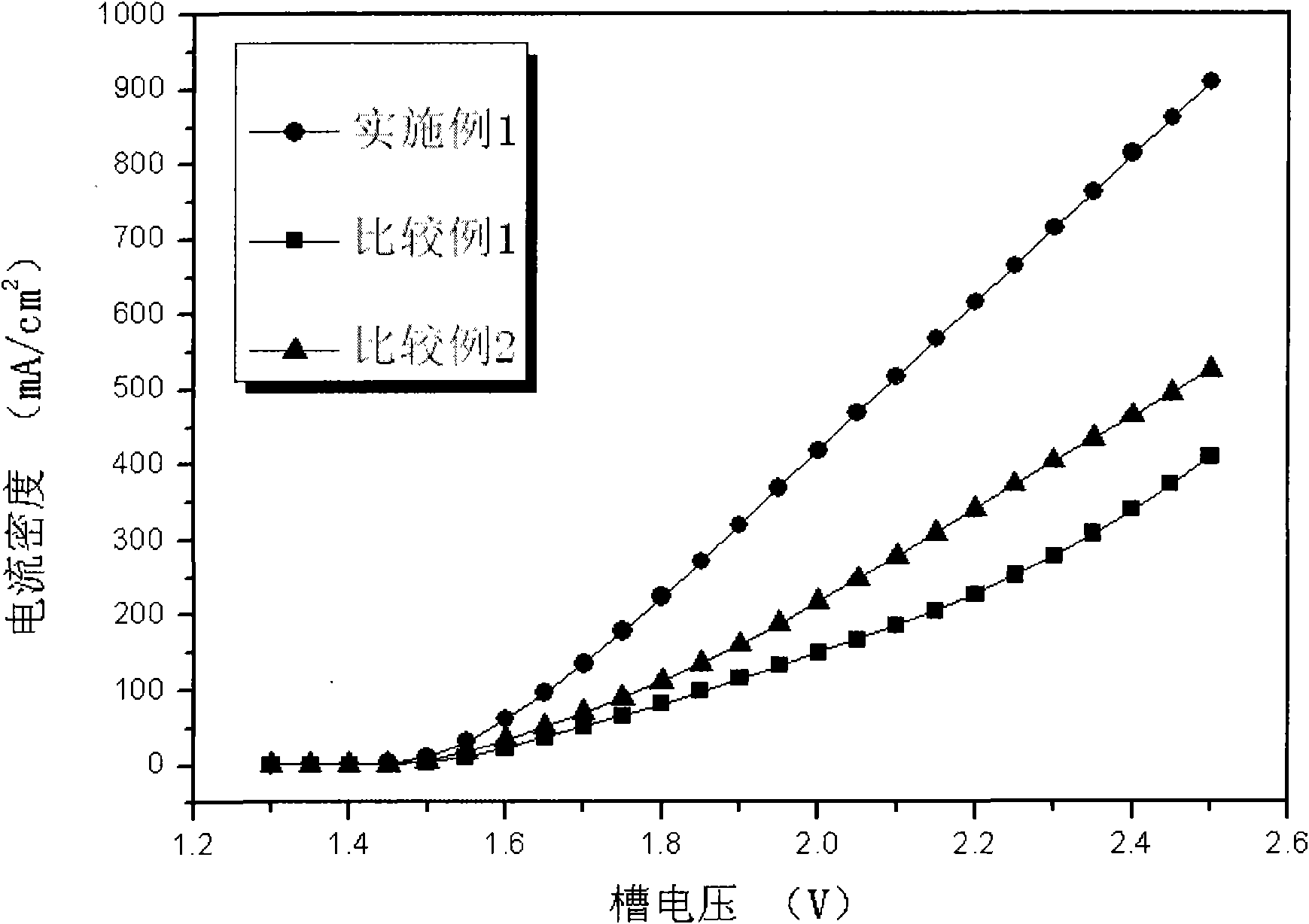

[0039] Example 1

[0040] Prepare electrodeposition precursor aqueous solution 100mL, which contains nickel sulfate 0.1M, sodium molybdate 0.02M, cobalt sulfate 0.1M, sodium citrate 0.2M, 2M KOH solution to adjust the pH to 10.00, traditional three-electrode system, carbon paper as work Electrode, saturated calomel electrode as reference electrode, platinum sheet as auxiliary electrode, constant current 20mA / cm at 25℃ 2 Electrodeposition for 1 hour, take it out to dry, and obtain an electrodeposited catalytic layer (ie, the first catalytic layer) containing nickel, molybdenum and cobalt.

[0041] Under ultrasonic and mechanical stirring, slowly dropwise add sodium borohydride solution (1.25g sodium borohydride dissolved in 50mL distilled water) to 100mL of the precursor aqueous solution with the same composition as the electrodeposition precursor aqueous solution, resulting in a large number of bubbles and black suspended particles. After the bubbles are generated, the solution is ...

Example Embodiment

[0050] Example 2

[0051] Prepare electrodeposition precursor aqueous solution 100mL, which contains nickel sulfate 0.1M, sodium molybdate 0.05M, cobalt sulfate 0.1M, sodium citrate 0.2M, ferrous sulfate 0.02M, 2M KOH solution to adjust the pH to 10.50, traditional three electrodes System, 200 mesh stainless steel mesh as working electrode, saturated calomel electrode as reference electrode, platinum sheet as auxiliary electrode, constant current 35mA / cm at 30℃ 2 Electrodeposition for 2 hours, take it out and dry it to obtain an electrodeposited catalytic layer (ie, the first catalytic layer) containing nickel, molybdenum and cobalt.

[0052] Under ultrasonic and mechanical stirring, slowly dropwise add sodium dihydrogen hypophosphite solution (5g sodium dihydrogen hypophosphite dissolved in 50mL distilled water) to 100mL of the precursor aqueous solution with the same composition as the electrodeposition precursor aqueous solution, resulting in a large number of bubbles, resulting ...

Example Embodiment

[0055] Example 3

[0056] Prepare electrodeposition precursor aqueous solution 100mL, which contains 0.2M nickel nitrate, 0.2M cobalt chloride, 0.05M ferric nitrate, 0.4M potassium sodium tartrate, concentrated ammonia solution to adjust the pH to 9.00, traditional three-electrode system, 200 mesh nickel mesh As the working electrode, the saturated calomel electrode was used as the reference electrode, and the platinum sheet was used as the auxiliary electrode. The electrode was deposited at a constant voltage of 1.4V at 25°C for 3 hours. That is, the first catalytic layer).

[0057] Under ultrasonic and mechanical stirring, slowly add sodium borohydride solution (1.25g sodium borohydride dissolved in 50mL distilled water) to 100mL of the precursor aqueous solution with the same composition as the electrodeposition precursor aqueous solution, resulting in a large number of bubbles and black suspended particles. After the bubbles are generated, the solution is filtered, the filter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap