Multiphase current type PWM rectifier based on dual controllable rectifier bridge of hybrid switch

A hybrid switching, multi-phase current technology, applied in the direction of converting AC power input to DC power output, electrical components, output power conversion devices, etc., can solve problems such as long off time, reducing circuit efficiency, and limiting circuit operating frequency. , to reduce the conduction loss, simplify the drive circuit, and adjust the output voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

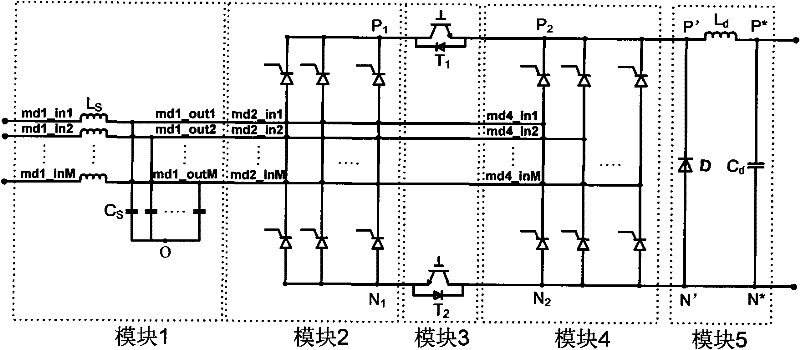

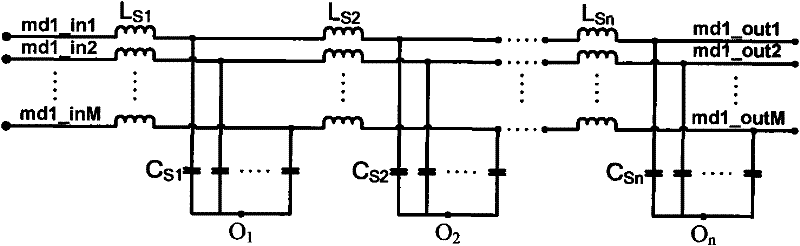

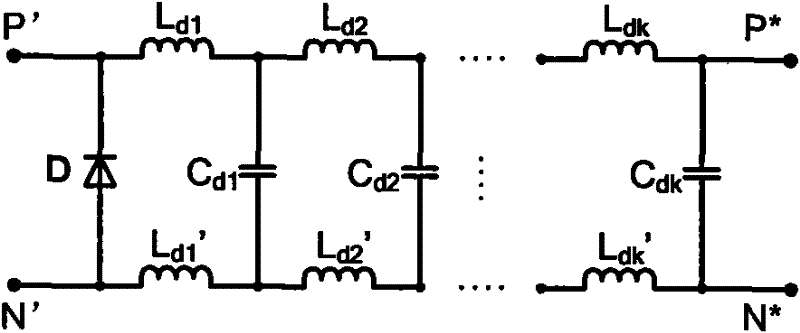

[0044] see figure 1 , the polyphase current type PWM rectifier based on the dual controllable rectifier bridge of hybrid switch of the present invention is made up of five modules, wherein module 1 is made up of M groups of LC filters, and module 2 and module 4 are thyristor M-phase rectifier bridge respectively , module 3 is two independently controlled reverse conduction fully controlled electronic switches T 1 , T 2 , module 5 is an LC filter with a freewheeling diode;

[0045] The input terminals md1_in1, md1_in2, ..., md1_inM of module 1 are respectively connected to the M-phase incoming lines of the power grid, and the output terminals md1_out1, md1_out2, ..., md1_out_M of module 1 are respectively connected to the bridge arms of each phase of module 2 and module 4 Points md2_in1, md2_in2, ..., md2_inM and md4_in1, md4_in2, ..., md4_inM, the ends of the M filter capacitors of module 1 are connected to the midpoint O;

[0046] Module 2 positive output P 1with module 4...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap