Welding trolley with bidirectional locking mechanism

A locking mechanism, welding trolley technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., to achieve the effect of compact coordination, easy use, maintenance and repair, compact and concise structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

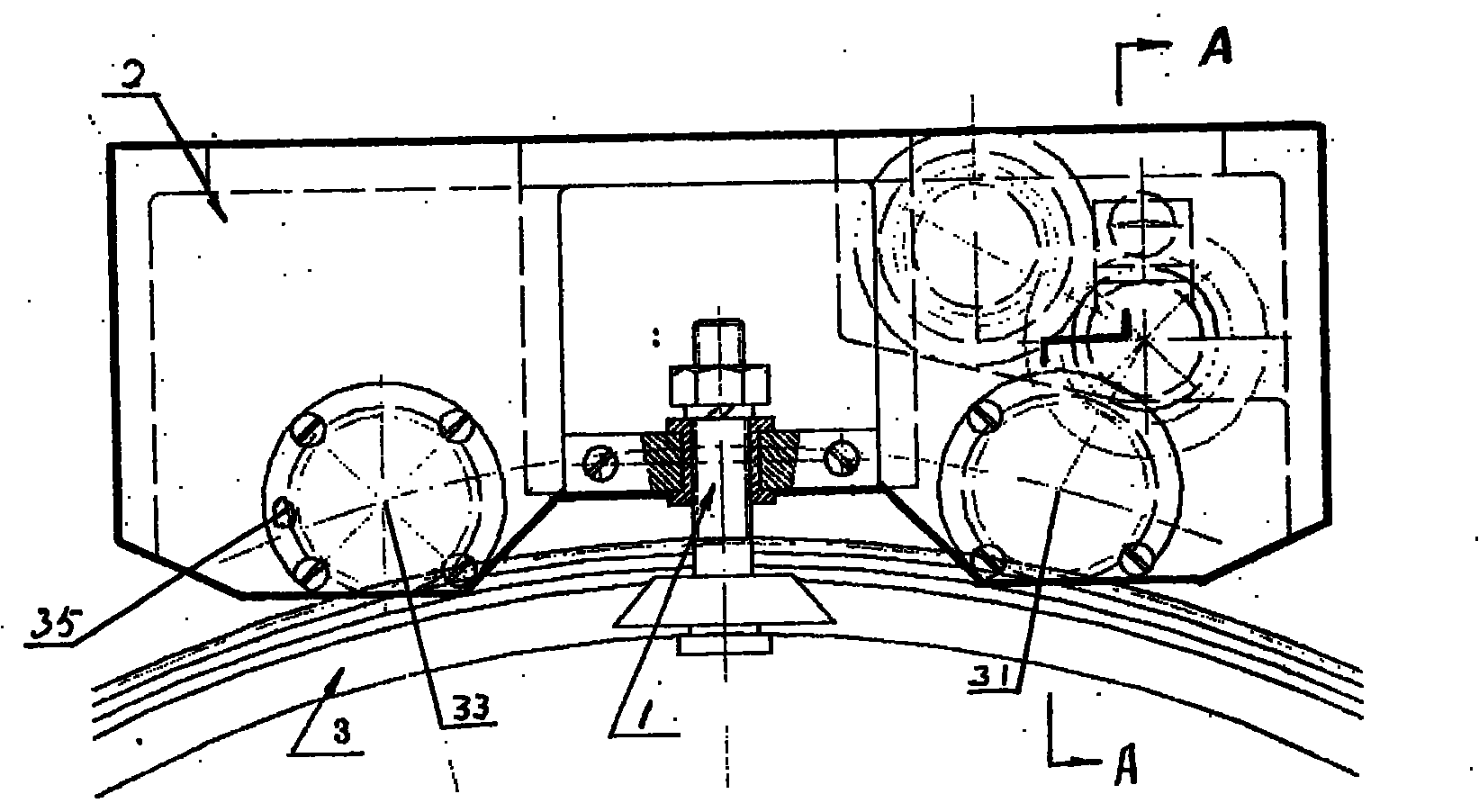

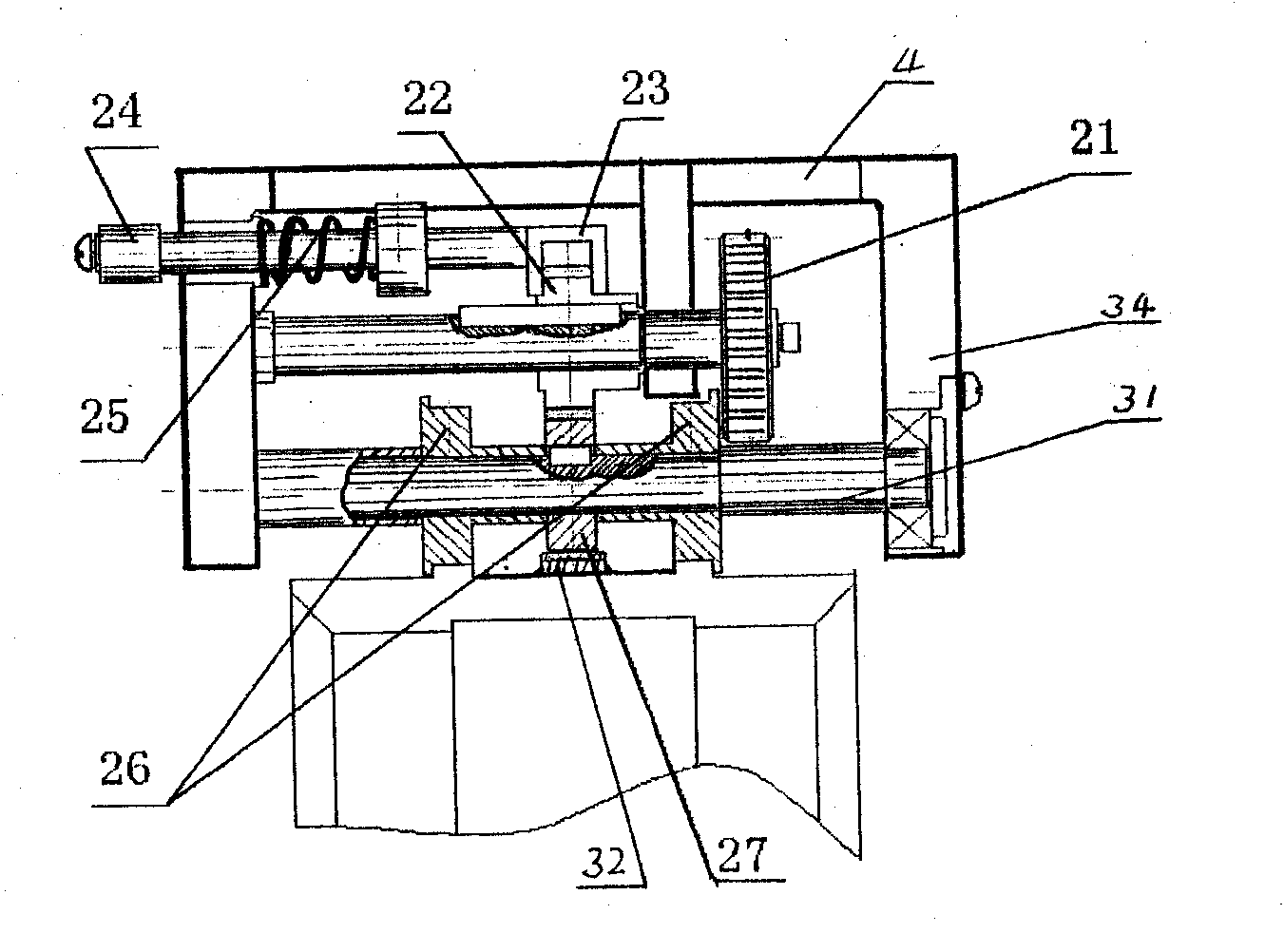

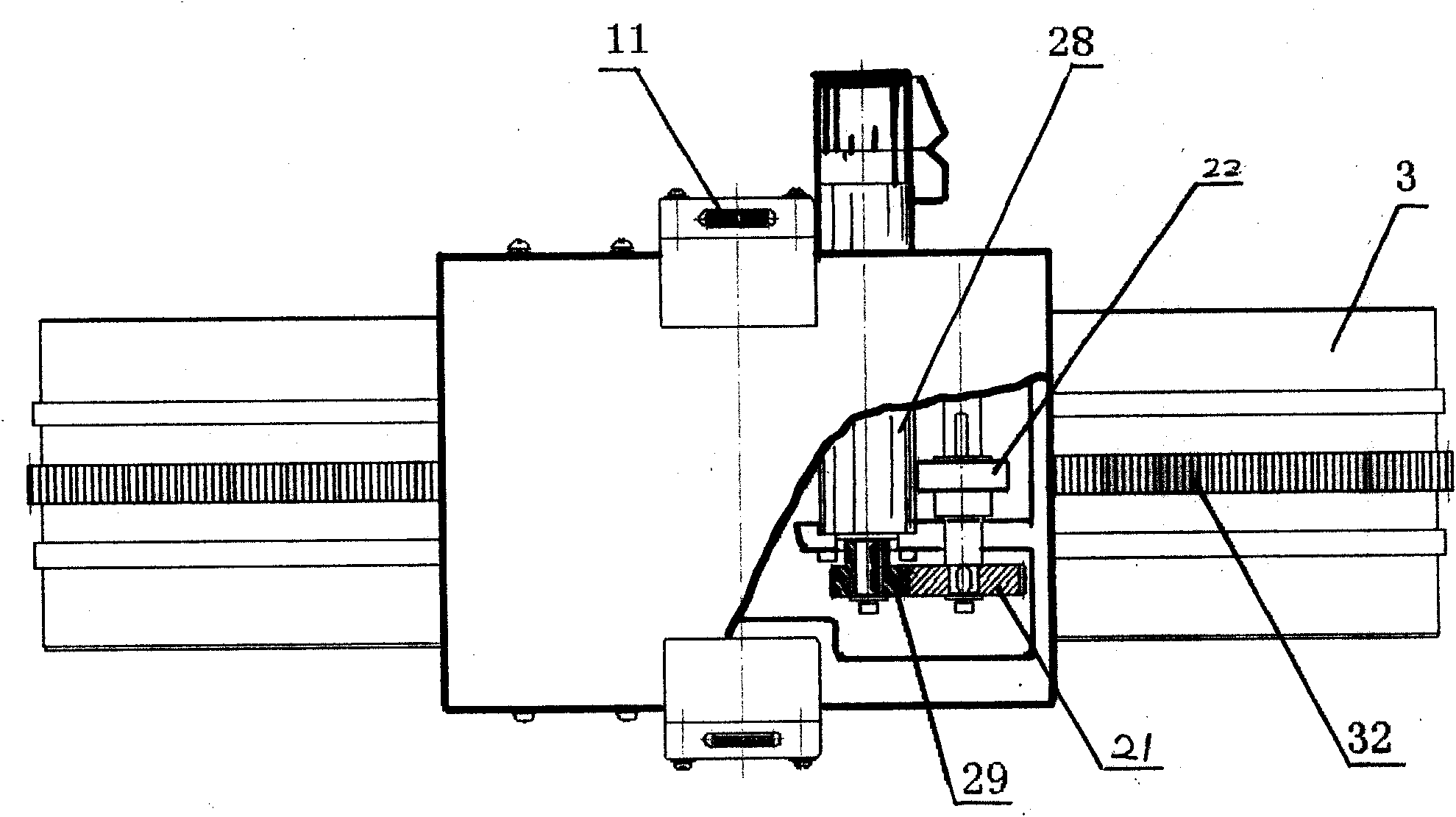

[0014] Depend on Figure 1 to Figure 5 As shown, a welding trolley with a two-way locking mechanism is mainly composed of a trolley locking mechanism 1 and a trolley traveling mechanism 2, wherein: a motor 28 with a reducer is connected with a motor shaft gear 29 through a key, and the motor shaft The gear 29 is meshed with the intermediate wheel A21, and the other side of the axis where the intermediate wheel A21 is located is connected to the intermediate wheel B22 with a long key, and the intermediate wheel B22 is meshed with the transmission gear 27 at the center of the front drive shaft 31, and the transmission gear 27 is finally welded to the The guide rack 32 in the center of the guide rail 3 is engaged, and a front drive wheel 26 is respectively installed on the left and right sides of the front drive shaft 31, so that the rotation of the motor 28 is converted into the rotation of a pair of front drive rollers 26, and the rear drive shaft 33 both sides Also each is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com