Method for accurately designing molded surface of autoclave forming fixture for composite products

A composite material and design method technology, which is applied in the field of precise design of composite material parts autoclave forming tooling surface, to achieve the effect of reducing development cost, improving design efficiency and quality, and improving design quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

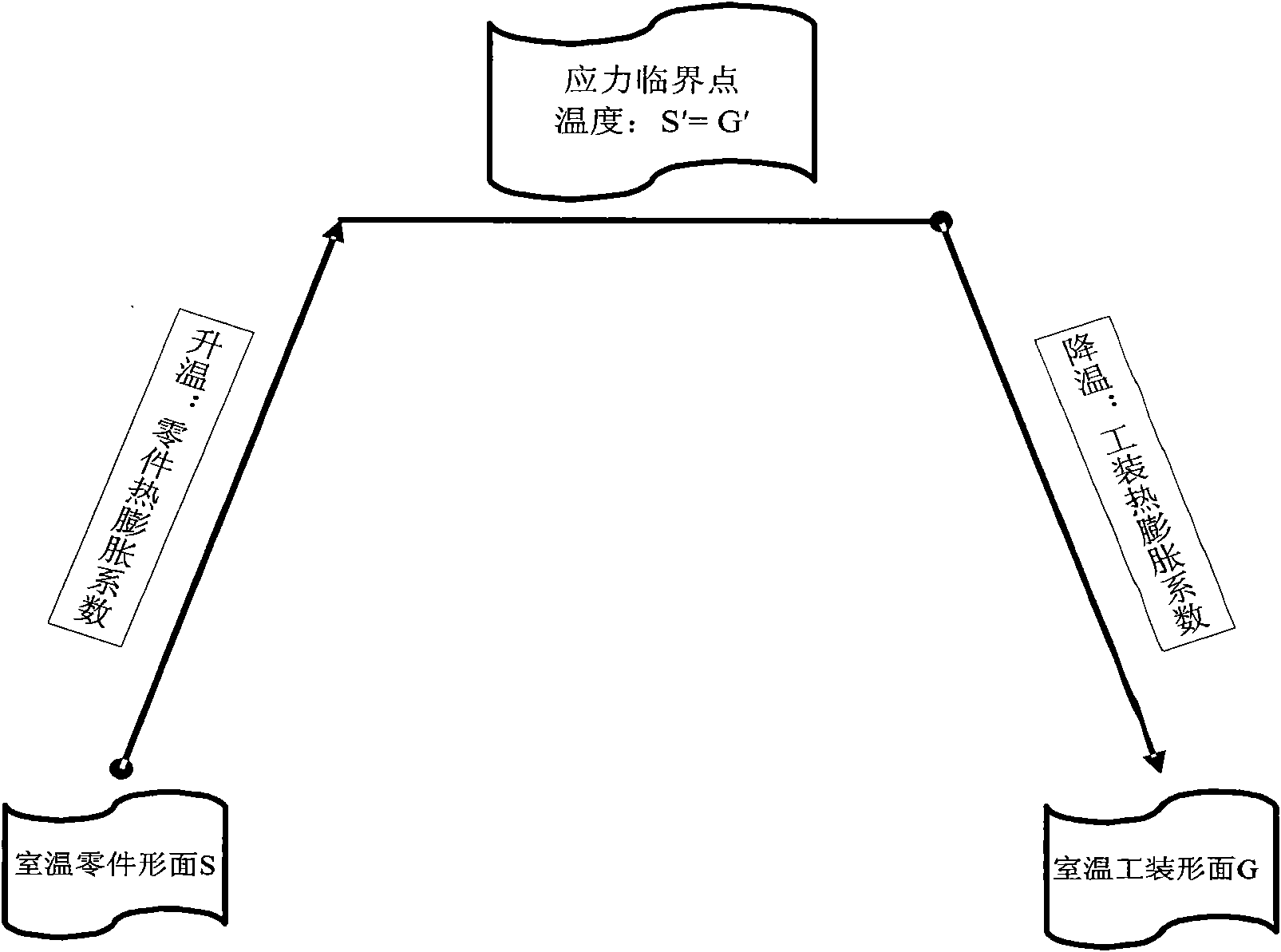

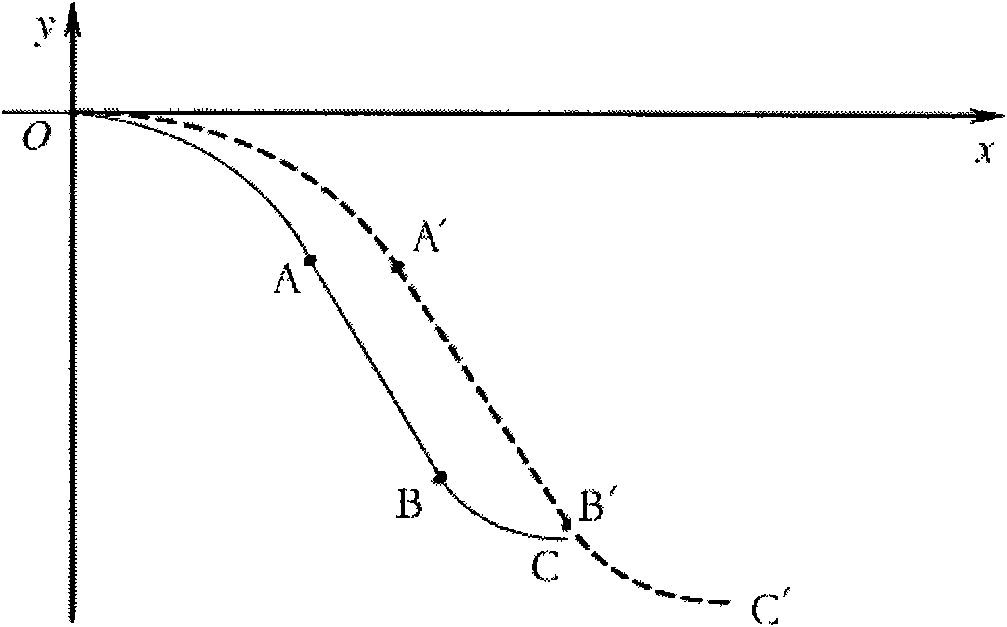

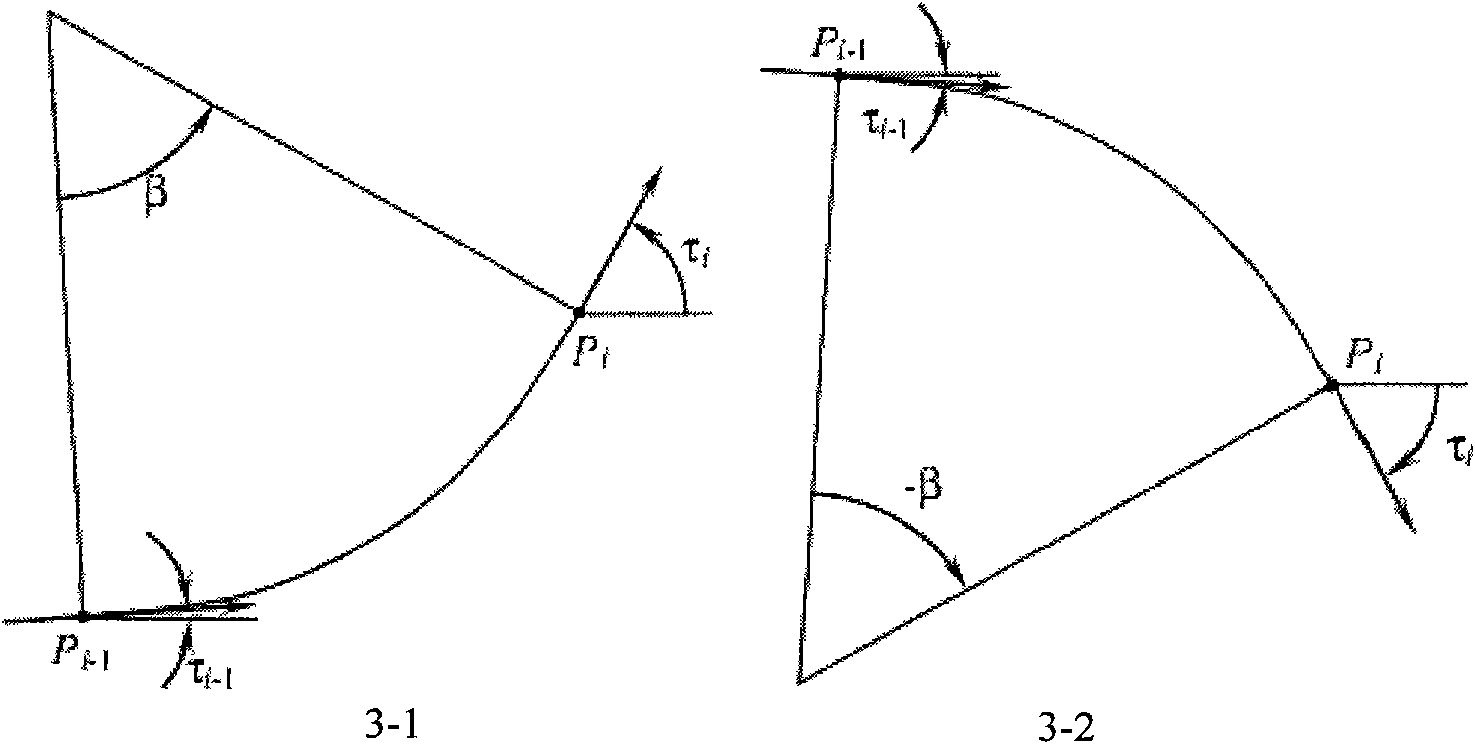

[0034] A method for accurately designing the surface of composite material autoclave forming tooling, which is suitable for the curing process curve of autoclave forming composite material parts, and under the premise that the thermal expansion coefficients of the parts and tooling are known, and is characterized in that the specific method as follows:

[0035] The first step: From the analysis of mechanical properties and physical states, thermosetting resins will go through four states during the curing process: ungelled glass state, viscous flow state, high elastic state and glass state after gelation; in the high elastic state Before, the composite material part changes from the liquid state to the high elastic state, the composite material part and the tooling surface are completely bonded, the composite material part shape changes with the tooling surface, and there is no stress between the two; as the curing process progresses , when the stress critical point is reached...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com