Movable screen automatic positioning system for screen printing machine

A screen printing machine, automatic positioning technology, applied in screen printing machines, printing machines, rotary printing machines and other directions, can solve the problem of too late for re-making, increase operating costs, etc., to save time, reduce operating costs, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

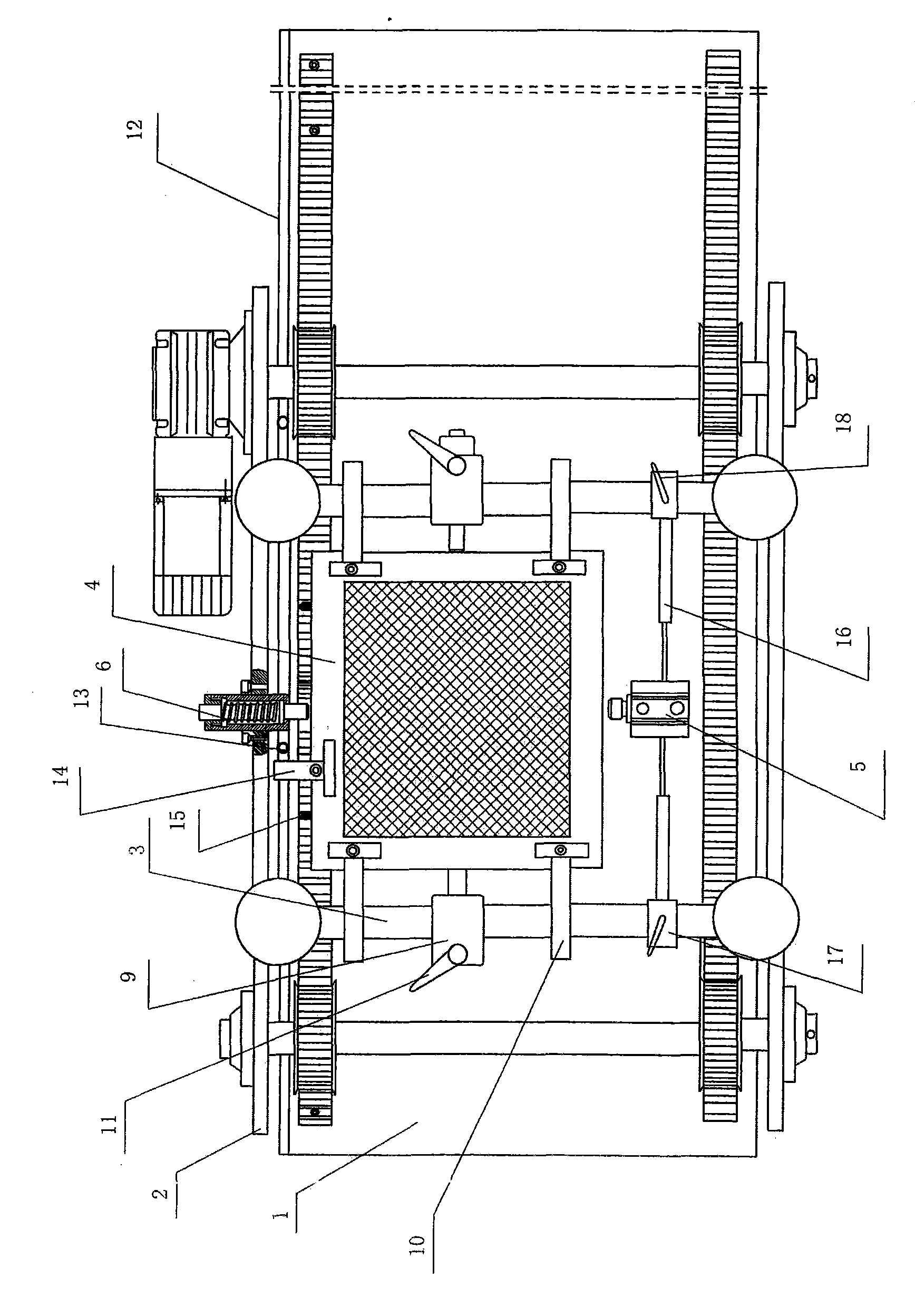

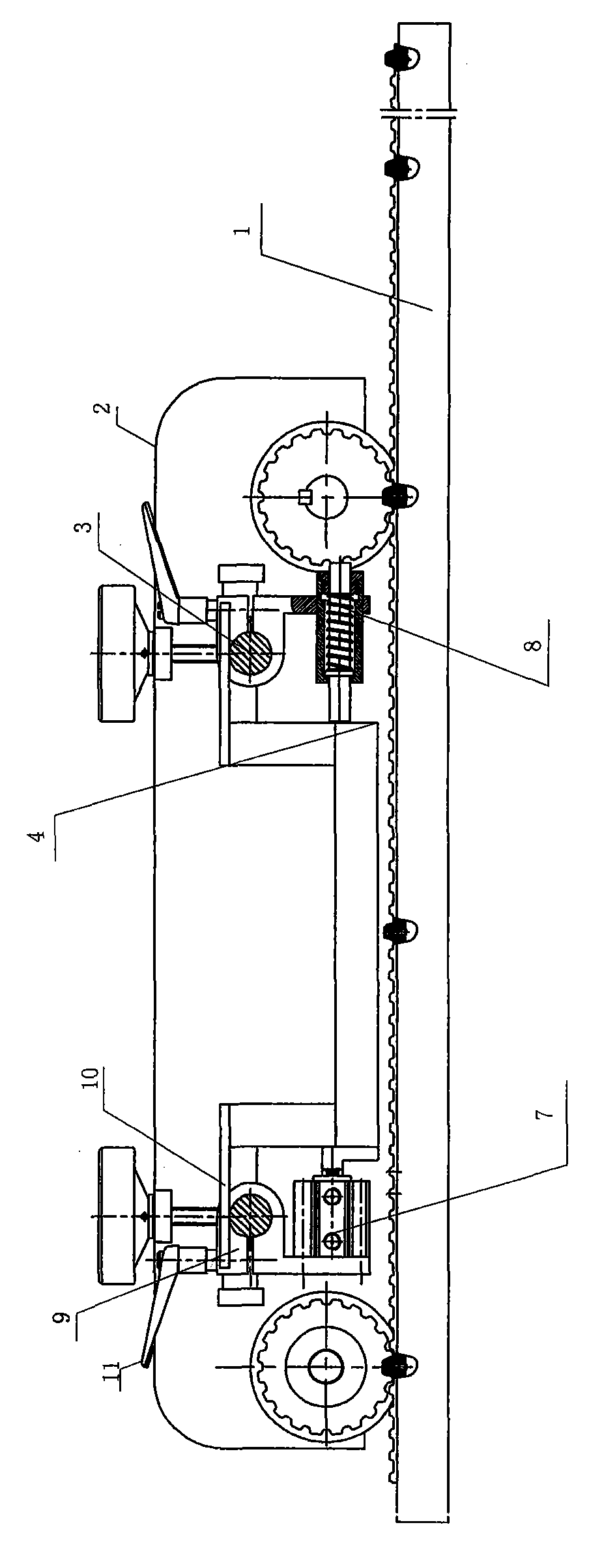

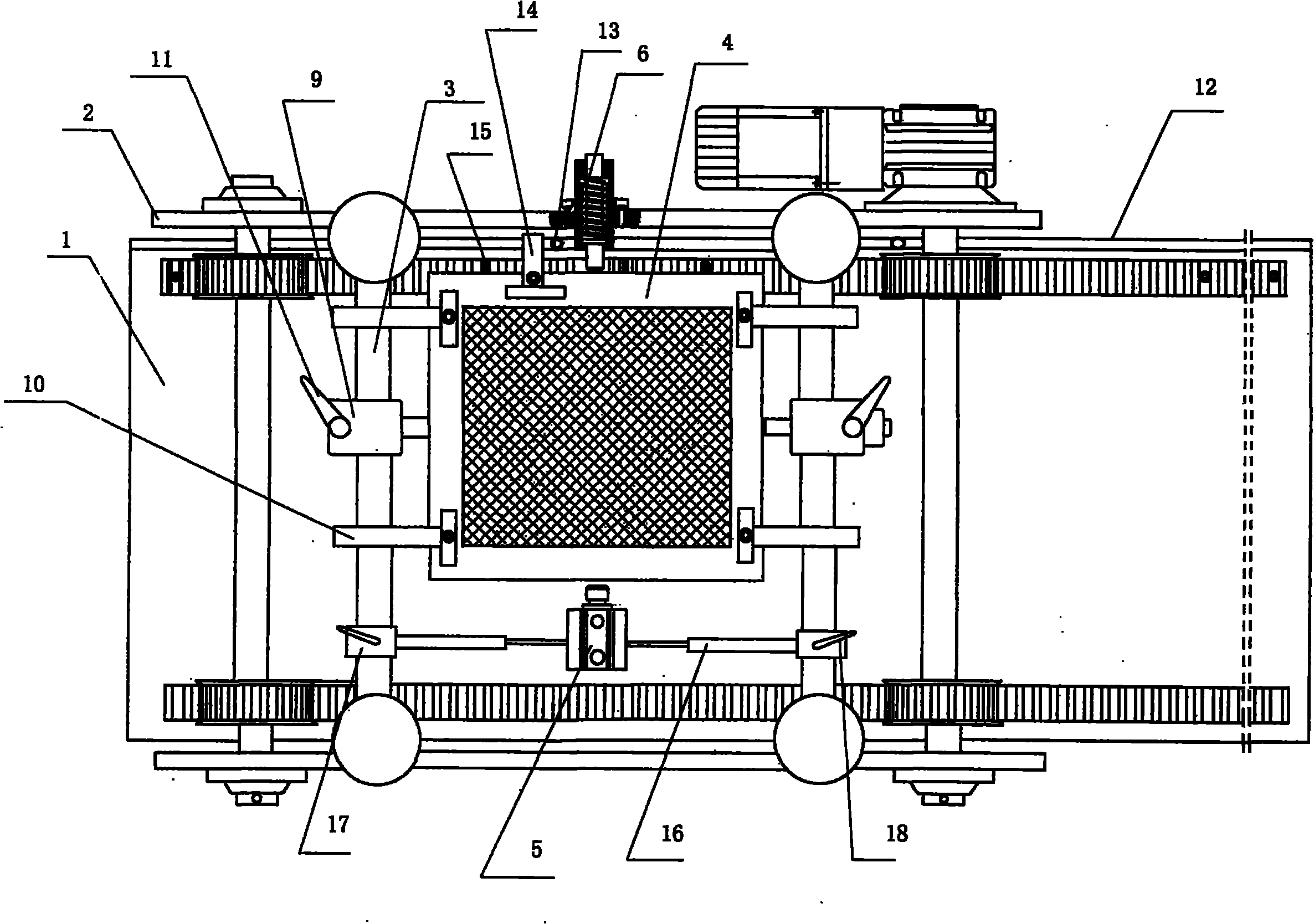

[0009] exist figure 1 and figure 2 Among them, the present invention is a movable screen automatic positioning system for a screen printing machine, which includes two guide rod shafts 3, and the guide rod shafts 3 are located on the printing frame 2 of the printing machine and are detachably connected to the printing frame 2. , a movable screen frame 4 is provided between the two guide rod shafts 3, and support plate groups are respectively provided on both sides of the movable screen frame 4, each support plate group includes two symmetrical T-shaped support plates 10, two T-shaped support plates 10 One end of the shaped support plate 10 is connected with the screen frame 4, and the other end is placed on the guide rod shaft 3. The two support plate groups slide on the guide rod shaft 3 and drive the screen frame 4 to move. There are positioning guide rails 12 on the edge, and several yards 13 are distributed on the positioning guide rail 12. One side in the longitudinal d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com