Impeller drive control mechanism of stationary crude oil washing machine

A technology of drive control and tank washing machine, which is applied in the direction of cleaning equipment for motor vehicles, oil tankers, and ship liquid tanks, etc. Main drive worm gear ratio and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

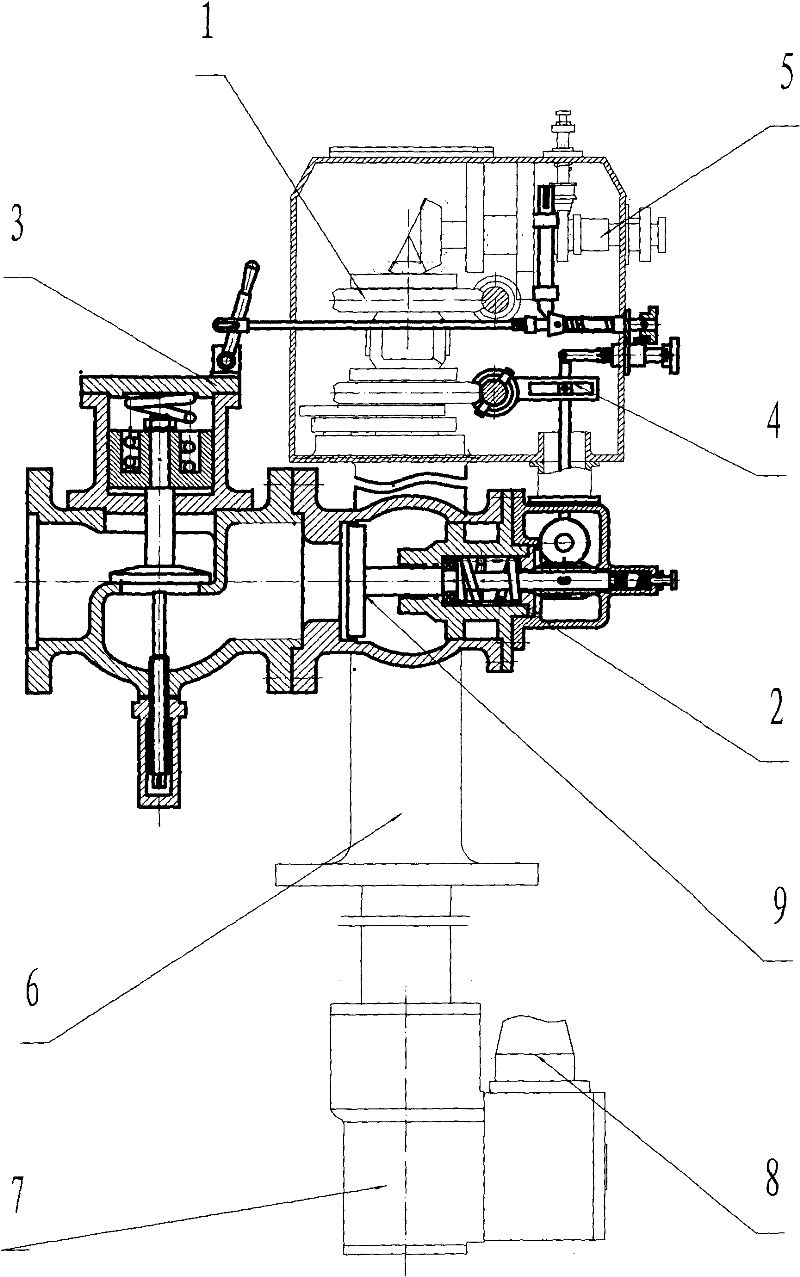

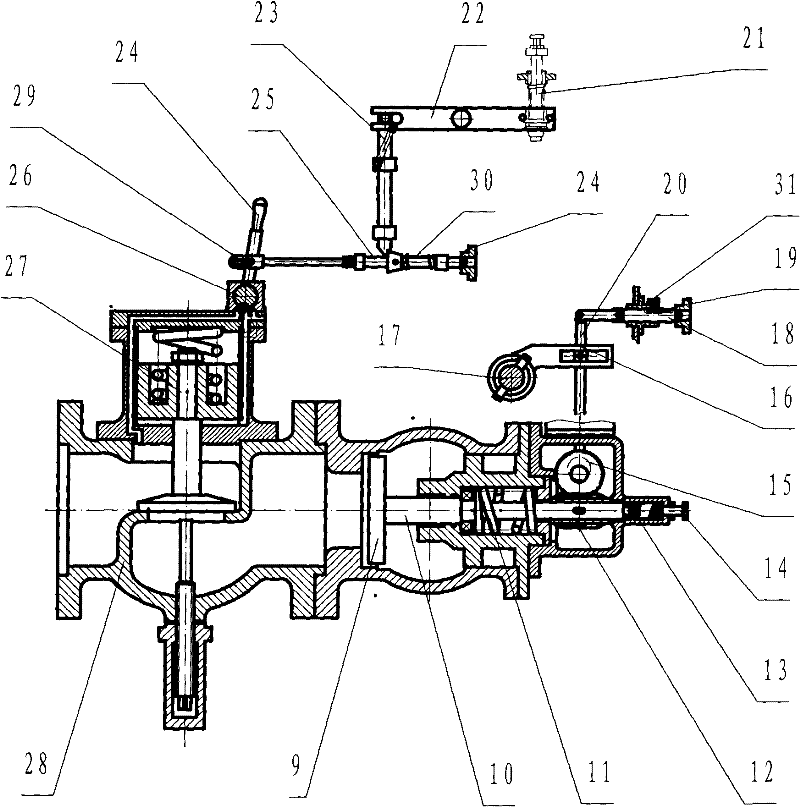

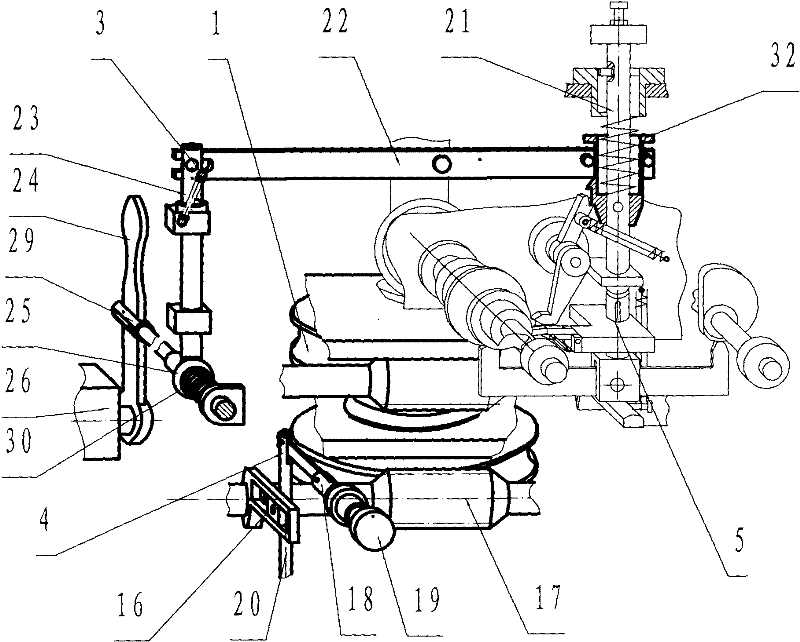

[0014] The present invention will be further described below in conjunction with accompanying drawing.

[0015] An impeller drive control mechanism of a stationary crude oil washing machine, including a main transmission part 1 arranged in the body, an impeller drive part 2, an impeller drive start and stop control part 3, and a nozzle horizontal speed adjustment mechanism connected to the impeller drive part 2 4. The impeller driving part 2 includes the impeller 9, the hydraulic control shut-off valve 28 at the front end of the impeller 9, the transmission shaft 10 connected to the rear end of the impeller 9, the main spring 11, the auxiliary spring 13 and the worm 12 set on the transmission shaft 10, and the worm 12 passes through The worm gear 15 meshed with it is connected with the nozzle horizontal rotation speed regulating mechanism 4 .

[0016] Described nozzle horizontal rotational speed regulating mechanism 4 comprises the eccentric wheel on the worm wheel 15, transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com