Subsection well completion system of bottom water reservoir horizontal well

A technology for bottom water reservoirs and horizontal wells, which is applied in the fields of special completion systems for horizontal wells, completion systems, and horizontal well completion systems. Difficult to balance and other problems, to achieve the effect of prolonging the production life of a single well, maintaining the stability of the wellbore wall, and improving the recovery of the reservoir

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

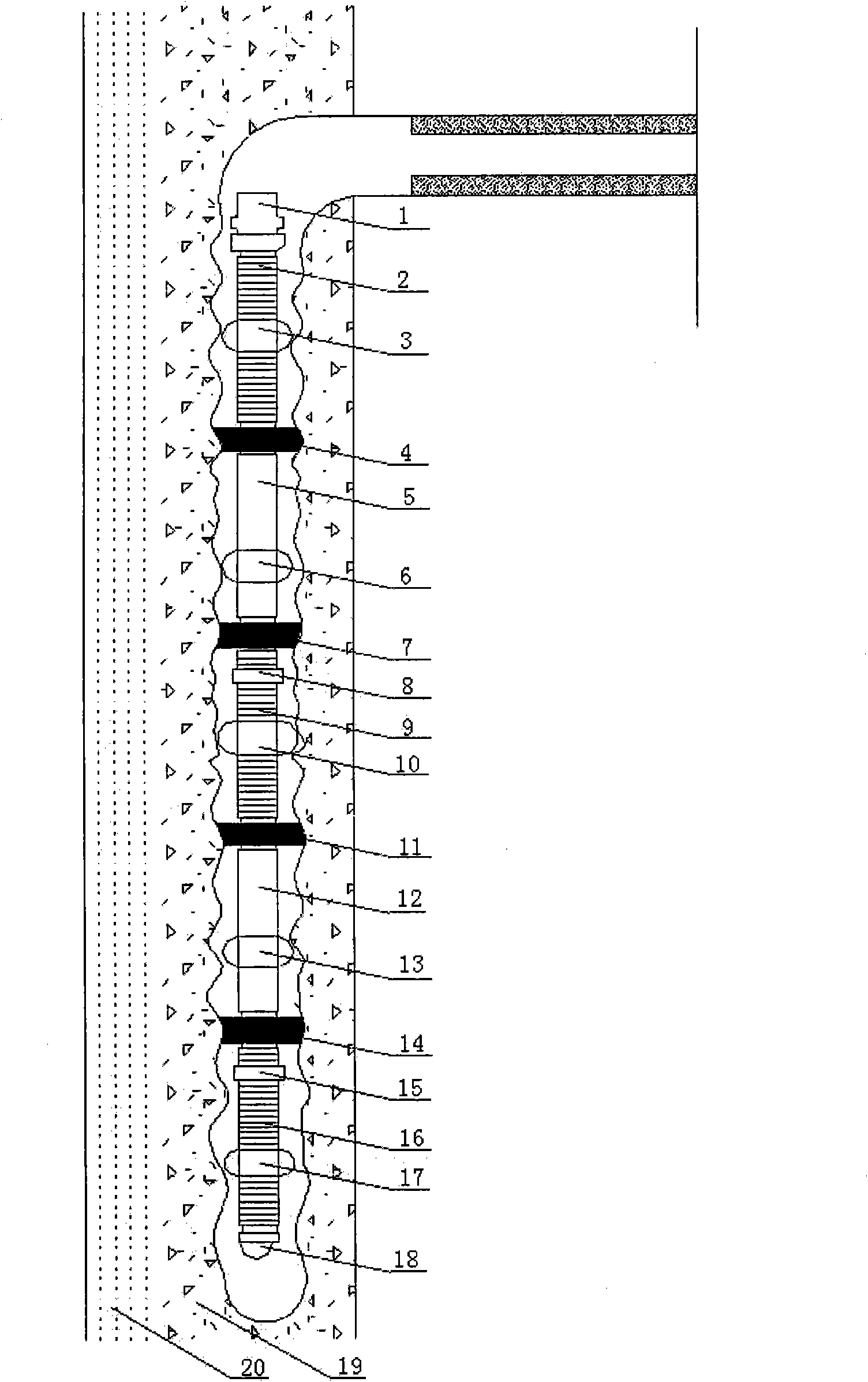

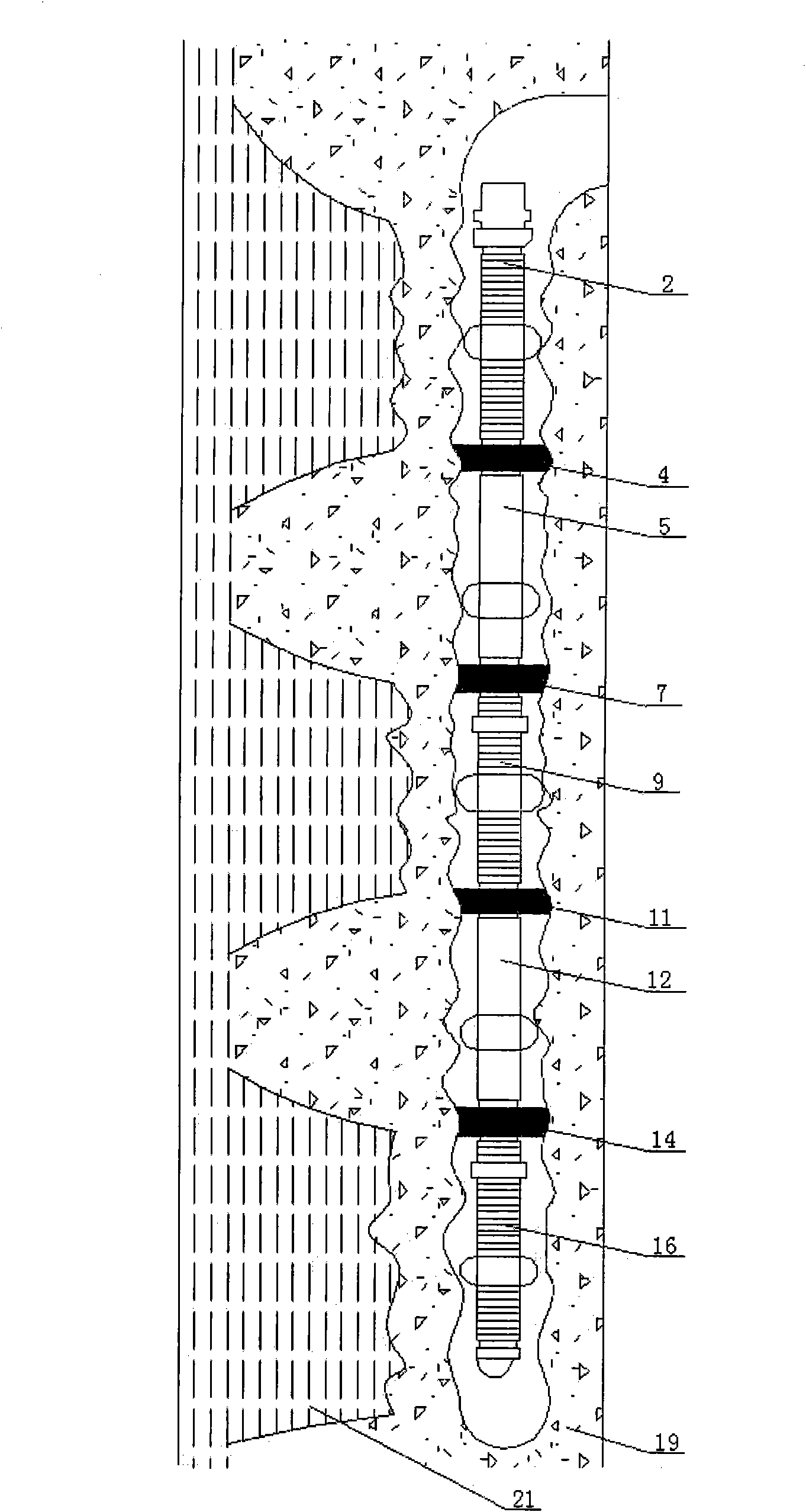

[0014] The details and work flow of the staged completion system for horizontal wells in bottom water reservoirs according to the present invention will be described in detail below in conjunction with the accompanying drawings.

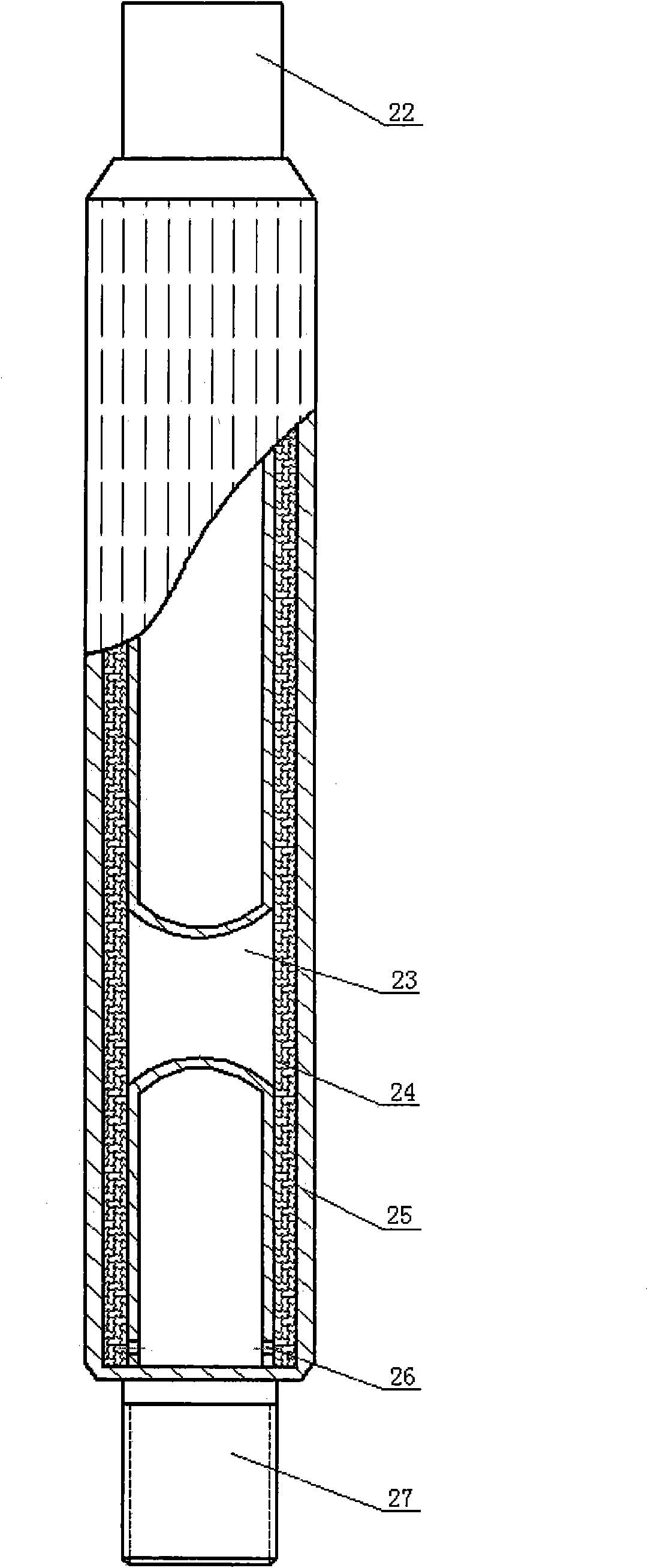

[0015] figure 1 A hand-off joint (1) at the heel end of the horizontal well shown is connected to the first section of the new-type flow control screen (2). The hand-off joint is used to run into the completion string. 16) section and the casing (5, 12) section alternately, and the packers (4, 7, 11, 14) are placed in the new flow control screen section (2, 9, 16) and the casing (5, 12) section respectively. ) sections, the new flow control screen (2, 9, 16) sections are used to exploit oil layers, casing (5, 12) sections and packers (4, 7, 11, 14) are used to isolate non-production interval, to seal formation pressure and prevent water channeling, the packers (4, 7, 11, 14) are removable hydraulic packers, and the safety joints (8, 15) are placed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com