Phase-controlled valve

A technology of phase control and flow limiting valve, which is applied in the direction of wellbore/well valve device, production fluid, wellbore/well components, etc. It can solve the problems of ICD water control tool failure water cut, etc., and eliminate the influence of annular flow , enhance oil recovery, and delay the effect of water ridges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

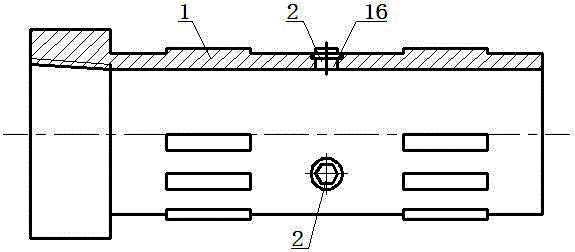

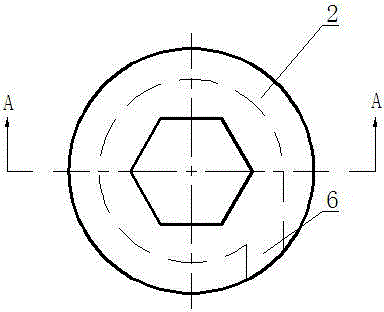

[0018] like figure 1 As shown, the phase control valve includes a base pipe 1 and a restrictor valve 2 threaded with the base pipe 1 .

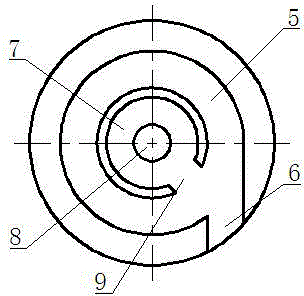

[0019] like figure 2 , image 3 , Figure 4 As shown, the flow limiting valve 2 includes an upper end cover 3 and a lower end cover 4, the lower end cover 4 is provided with a liquid inlet 6 and an annular flow channel 5 communicating with the liquid inlet 6, the annular flow channel 5 is arc-shaped, Thus, the fluid guided into the annular flow passage 5 flows in a circular arc shape, and the annular flow passage 5 encloses the control chamber 7, and the side wall of the control chamber 7 is provided with a communication ring flow passage 5 and the control chamber. The flow channel 9 of the chamber 7, the opening of the flow channel 9 faces the liquid inlet 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com