Automatic phase selection control valve

A technology for phase selection and valve control, which is applied in wellbore/well valve devices, production fluids, wellbore/well components, etc., and can solve problems such as the inability to fully utilize the advantages of horizontal wells, the rapid rise of water cut, and the waste of resources. , to achieve the effect of improving the balance control effect, eliminating the influence of the annular flow, and eliminating the toe and heel effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

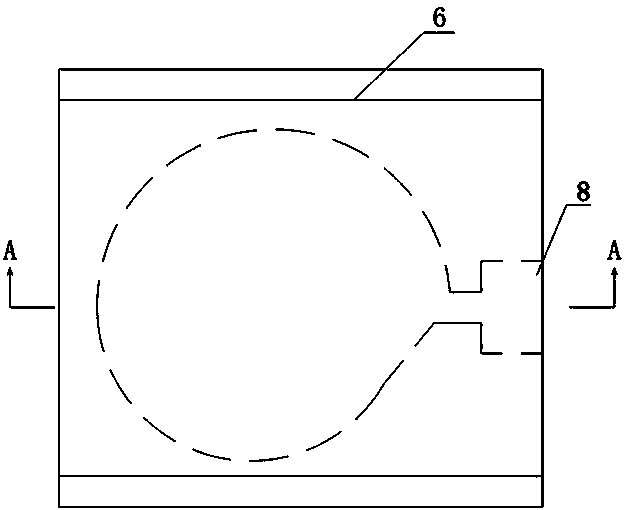

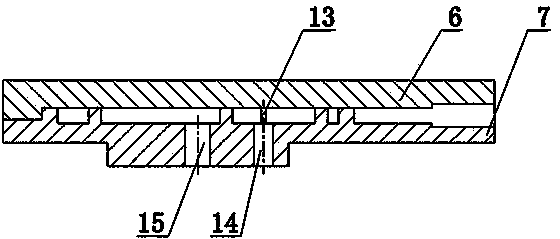

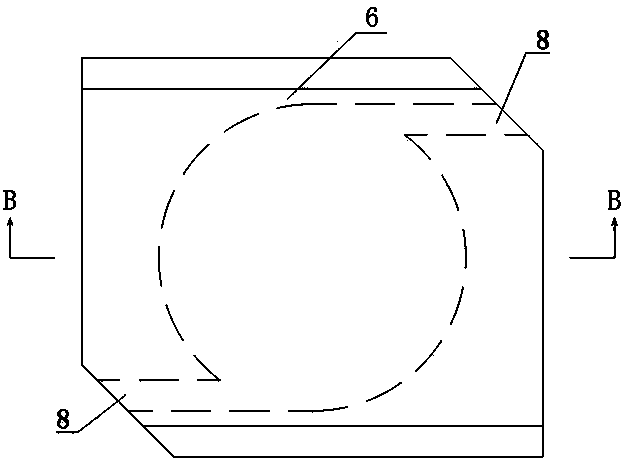

[0023] Such as figure 1 As shown, the automatic phase selection control valve includes a base pipe 1, and the outside of the base pipe 1 is sequentially set with an end cover 2, an outer ring sleeve 3 and a screen pipe 4 along the direction from front to back, and the end cover 2 is tightly connected with the base pipe 1 , in this implementation, the end cap 2 is welded to the base pipe 1, and a sealing ring is provided between the cylindrical inner wall of the end cap 2 and the outer surface of the base pipe 1, and the front end of the outer ring sleeve 3 and the rear end of the end cap 2 Tightly connected, the front end of the screen pipe 4 is connected to the rear end of the outer ring sleeve 3, and a swirl restrictor 5 is installed in the gap between the outer ring sleeve 3 and the base pipe 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com