Intelligent ventilation system of grain depot

A ventilation system and intelligent technology, applied in the direction of control/regulation system, non-electric variable control, instrument, etc., can solve problems such as difficult to respond quickly, low reliability, time-consuming, etc., to achieve wide application and promotion value, automation degree The effect of high and low working intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

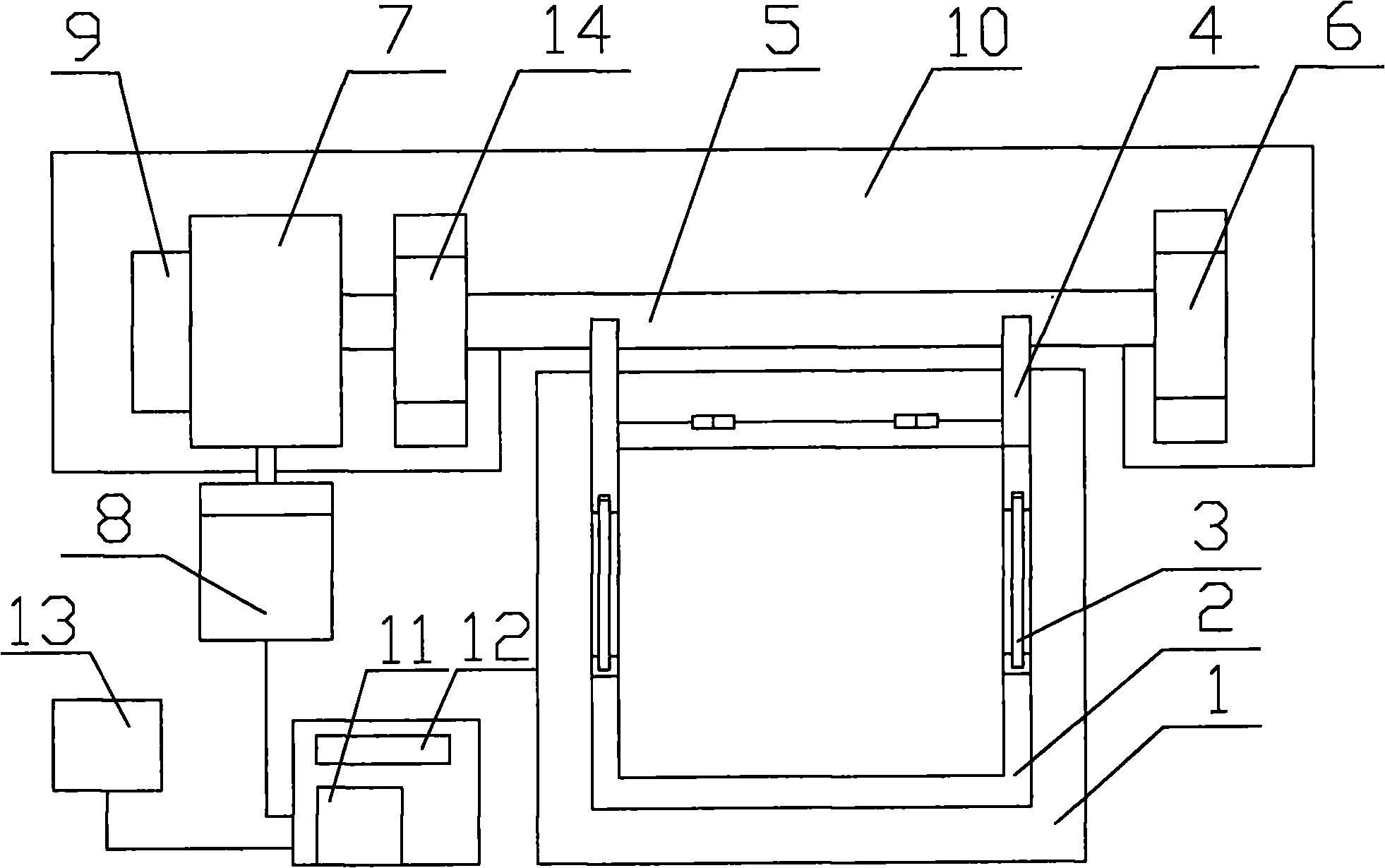

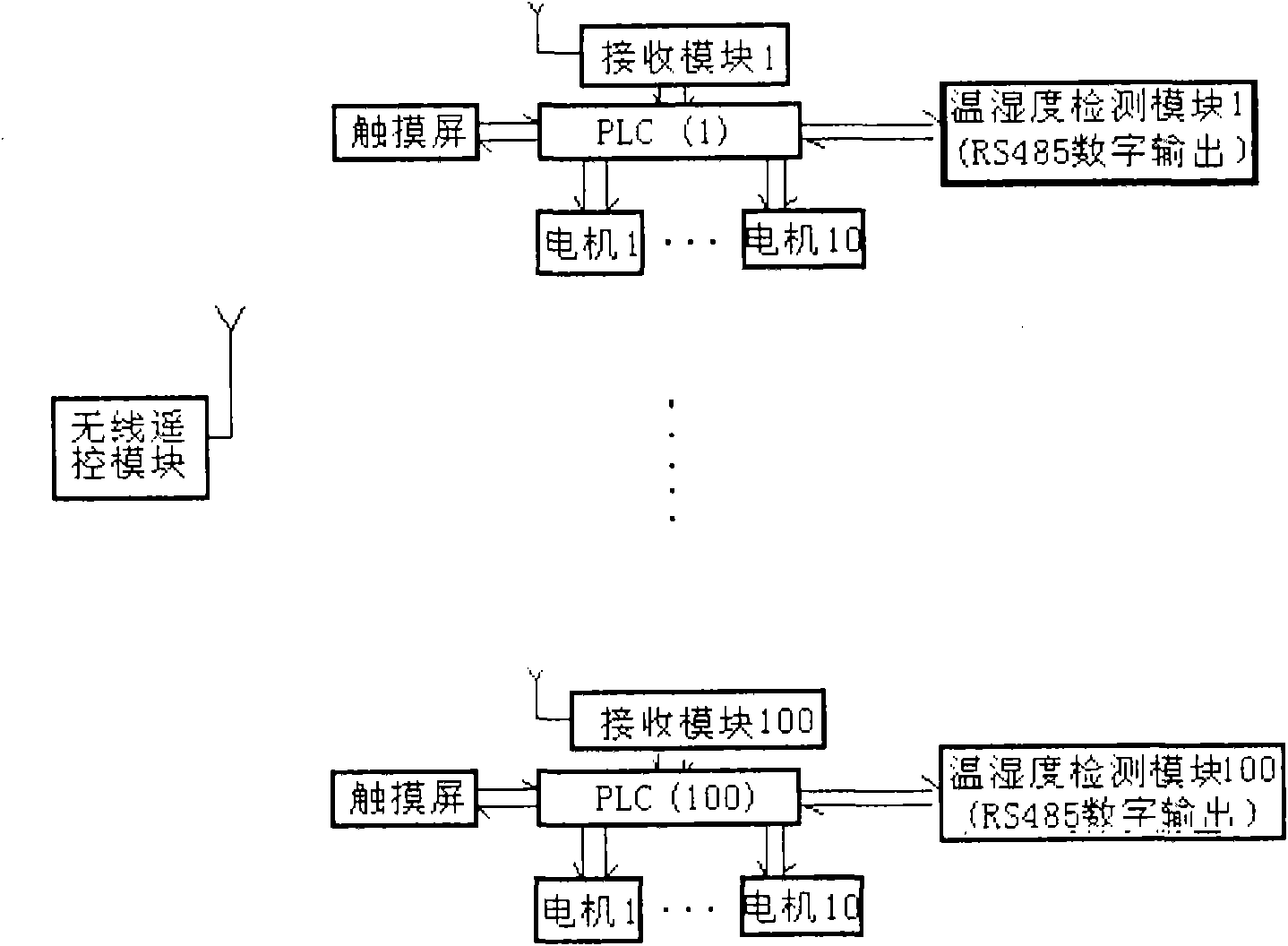

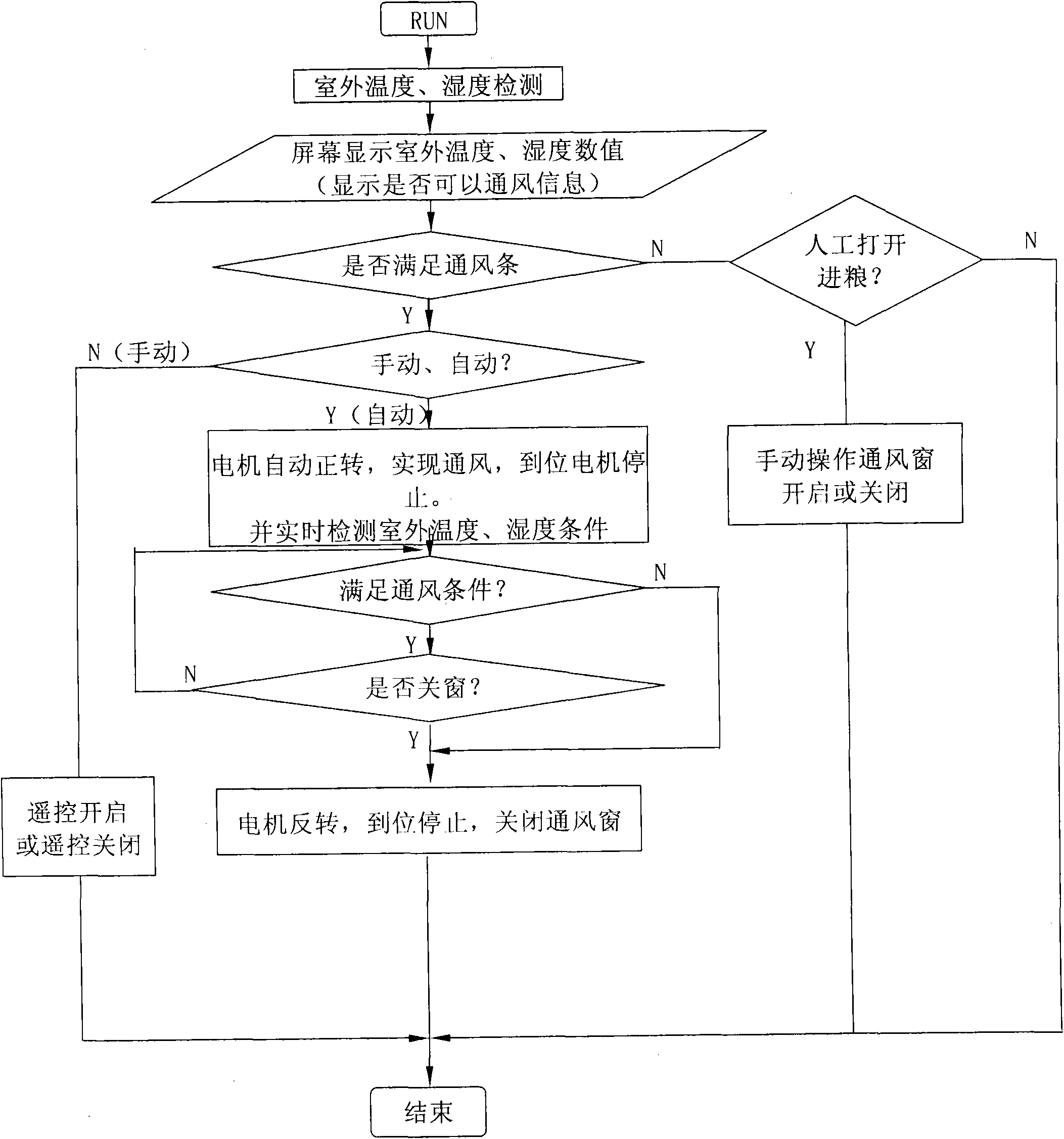

[0014] like figure 1 An embodiment of the intelligent ventilation system of the grain depot of the present invention is shown, including a ventilation louver mechanism, a control mechanism and a detection mechanism 13, between the louver mechanism and the control mechanism, the control mechanism and the detection mechanism 13 are connected by wires, the ventilation louver mechanism includes a ventilation window fixed window frame 1, the bottom inner surface of the ventilation window fixed window frame 1 and the inner surfaces of both sides are hinged with a ventilation window moving window 2, and the ventilation window moving window 2 is composed of Two vertical parts and one horizontal part are composed, the horizontal part is arranged between the two vertical parts, and the ends of the two vertical parts of the ventilation window moving window 2 are hinged with a vertically arranged drive link 4 through a pull rod 3. , each drive connecting rod 4 is welded on the same horizo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap