Label printing system

A printing system and labeling technology, which is applied in the direction of digital output to printing unit, etc., can solve the problem of low printing efficiency of the label printing system, the inability of multiple different printers to print different component labels, and the inability to unify and update the label version in time and other issues, to achieve the effect of improving label printing efficiency and printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

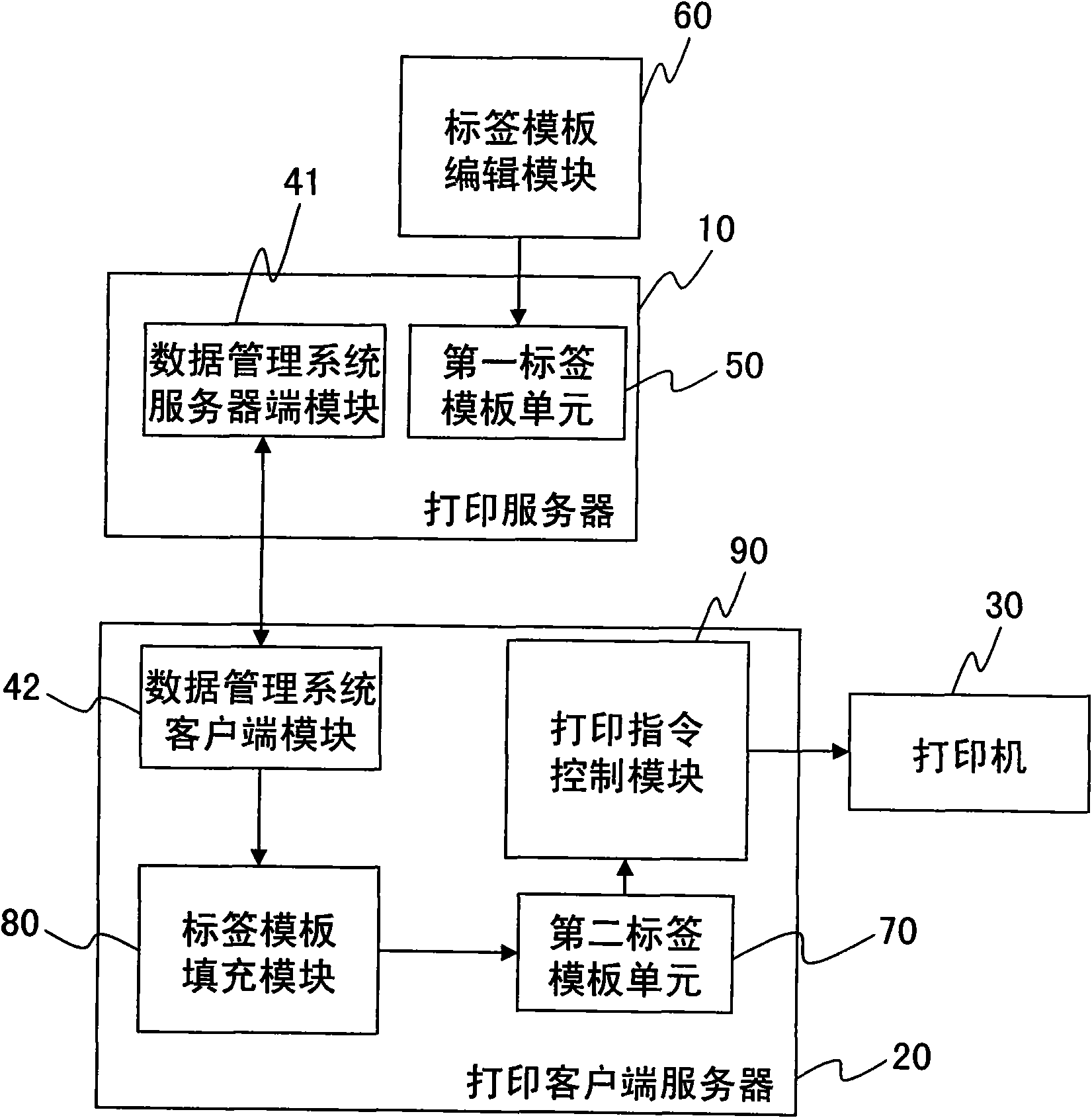

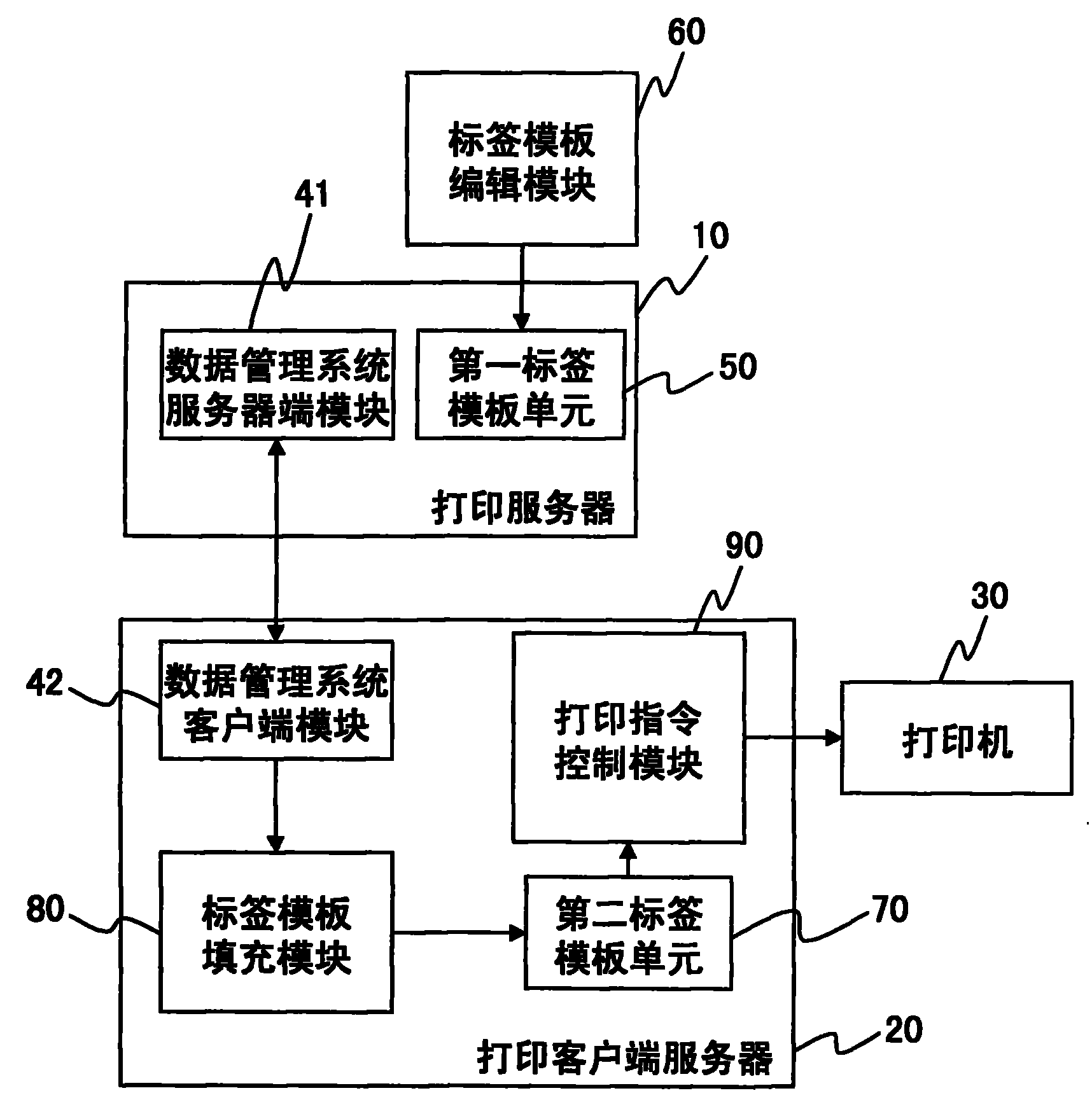

[0025] Please refer to figure 1 , which is a schematic diagram of the system architecture of the label printing system of the present invention. As shown in the figure, a label printing system provided by the present invention includes:

[0026] Print server 10; print client server 20; printer 30; wherein, the label printing system further includes a set of label printing request information that can be input from the print server 10 to the print client server 20 according to the operator and execute Modules and units of corresponding printing instructions, including:

[0027] A data management system server module 41, the data management system server module 41 is installed in the print server 10;

[0028] Data management system client module 42, the data management system client module 42 is installed in the print client server 20, and the data management system client module 42 can communicate with the data management system server module 41 and interact with related data ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com