Method for producing liquid crystal polymer multilayer structure

A technology of liquid crystal polymers and manufacturing methods, applied in the direction of lamination, devices for coating liquid on surfaces, lamination devices, etc., can solve the problems that transparent films of liquid crystal polymers cannot be obtained, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0173] The present invention will be described below based on Examples (Examples 1-7, 9, 10, 12, 18-21) and Comparative Examples (Examples 8, 11, 13-17), but the present invention is not limited thereto.

[0174] (molecular weight)

[0175] The polystyrene-equivalent number average molecular weight was calculated|required using GPC (manufactured by TOSOH CORPORATION, brand name: HLC-8220).

[0176] (Measurement of melting point, glass transition point, phase transition temperature)

[0177] Using DSC (manufactured by Bruker AXS K.K., trade name: DSC3100S), the peak temperature was identified, and the temperature increase rate was set at 10°C / min. In addition, identification of liquid crystal phases and crystals was performed by observation using a polarizing microscope (manufactured by Olympus Corporation, trade name: BX-51).

[0178] (in-plane unevenness)

[0179] Two polarizing plates were formed into a state of crossed nicols, and in-plane unevenness of the sample was ob...

Synthetic example 1

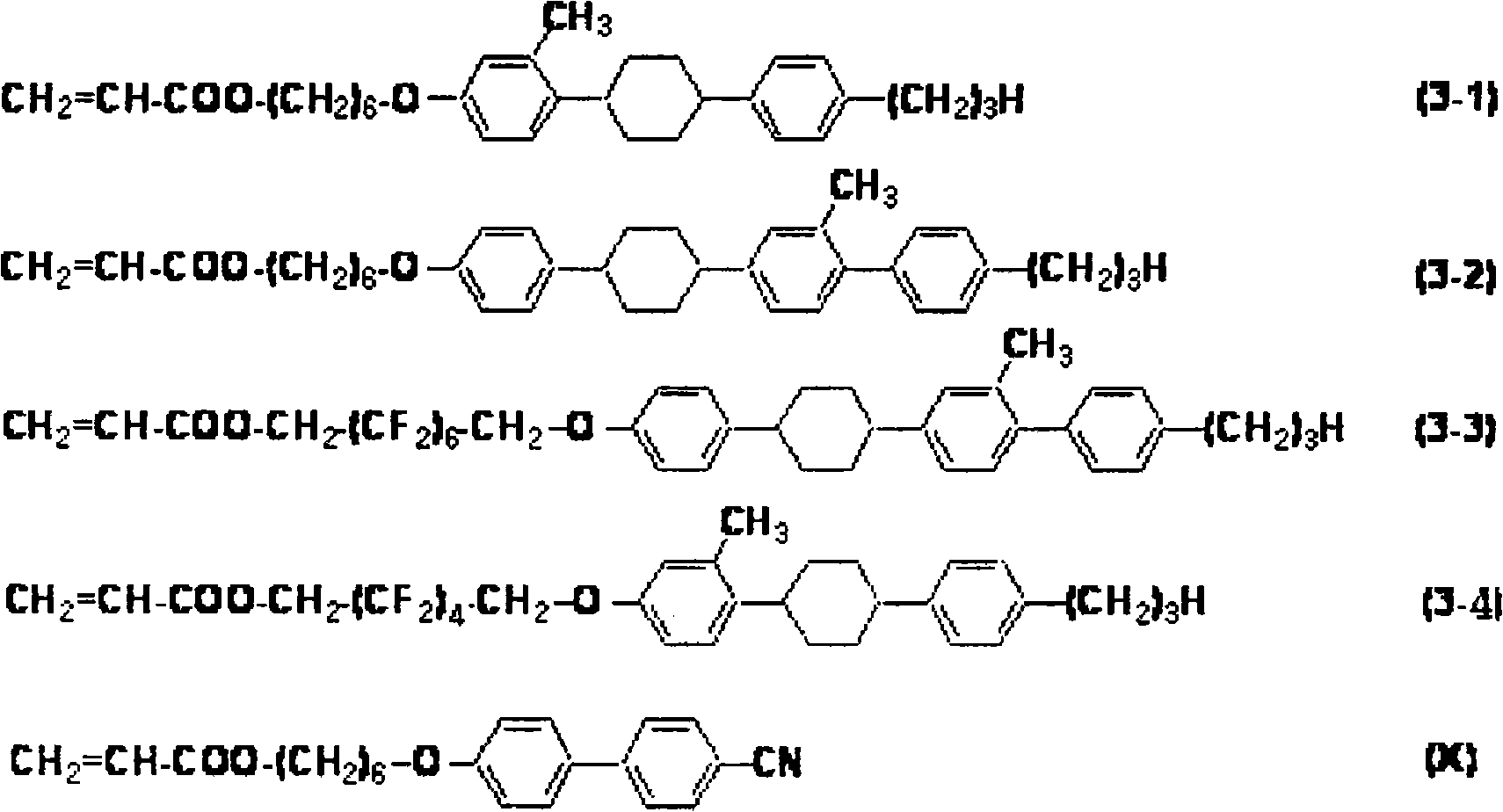

[0187] [Synthesis Example 1] Synthesis of Monomer (3-1) Used in Examples

[0188] Monomer (3-1) was synthesized by the following synthetic route. The specific details are described below.

[0189] [chemical formula 2]

[0190]

[0191] Synthesis of compound (13):

[0192] Magnesium (6.45g) was added in a 1L four-necked flask equipped with a reflux device and a dropping device, and 4-propylbromobenzene (compound (11)) dissolved in dehydrated tetrahydrofuran (200mL) was added dropwise for 60 minutes under nitrogen flow. , 50g) solution. After the dropwise addition, 100 mL of dehydrated tetrahydrofuran was further added dropwise and stirred for 2 hours to prepare a Grignard reagent. Next, the four-neck flask was cooled to 0°C, and 1,1'-bicyclohexane-1,4-dione monoethylene glycol ketal dissolved in dehydrated tetrahydrofuran (200 mL) was added dropwise over 60 minutes under a nitrogen stream. (compound (12), 35.1 g) solution. After completion of the dropwise addition, the...

Synthetic example 2

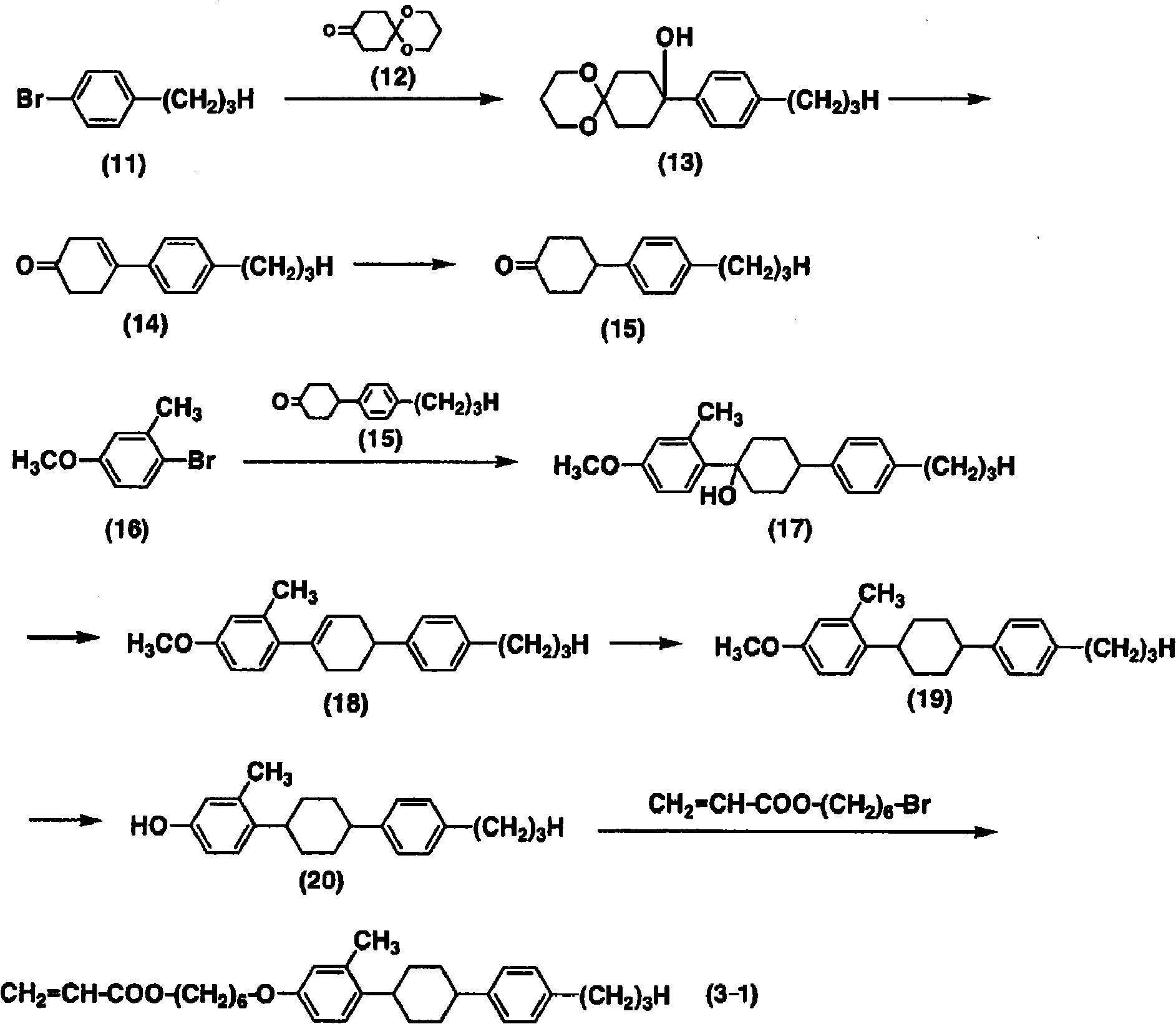

[0212] [Synthesis Example 2] Synthesis of Monomer (3-3) Used in Examples

[0213] Monomer (3-3) was synthesized according to the synthetic route shown below. The details are described below.

[0214] [chemical formula 3]

[0215]

[0216] Synthesis of compound (32):

[0217] Compound (31) (50.0 g) and 3,4-dihydropyran (7.0 mL) were added in a 5 L four-necked flask equipped with a reflux device and a stirrer, and dichloromethane (3500 mL) was dissolved in p-toluenesulfonic acid ( 0.54 g) was reacted at room temperature to obtain 20.68 g of compound (32).

[0218] Synthesis of compound (29):

[0219]Compound (32) (24.87 g), diethyl ether (500 mL), and triethylamine (14 mL) were added to a 1 L four-necked flask equipped with a reflux device and a stirrer. After cooling to 0°C, 1,1,2,2,3,3,4,4,4-nonafluorobutanesulfonyl fluoride (12.31 mL) was added, the temperature was slowly raised to room temperature, and the mixture was stirred for 40 hours. Water (300 mL) was added, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com