Electrical contact

A technology of electrical contacts and contacts, applied in the direction of circuits, electrical components, coupling devices, etc., can solve problems such as damage, damage to plug contacts, and hinder the manufacture of cables, so as to prevent winding and simplify production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

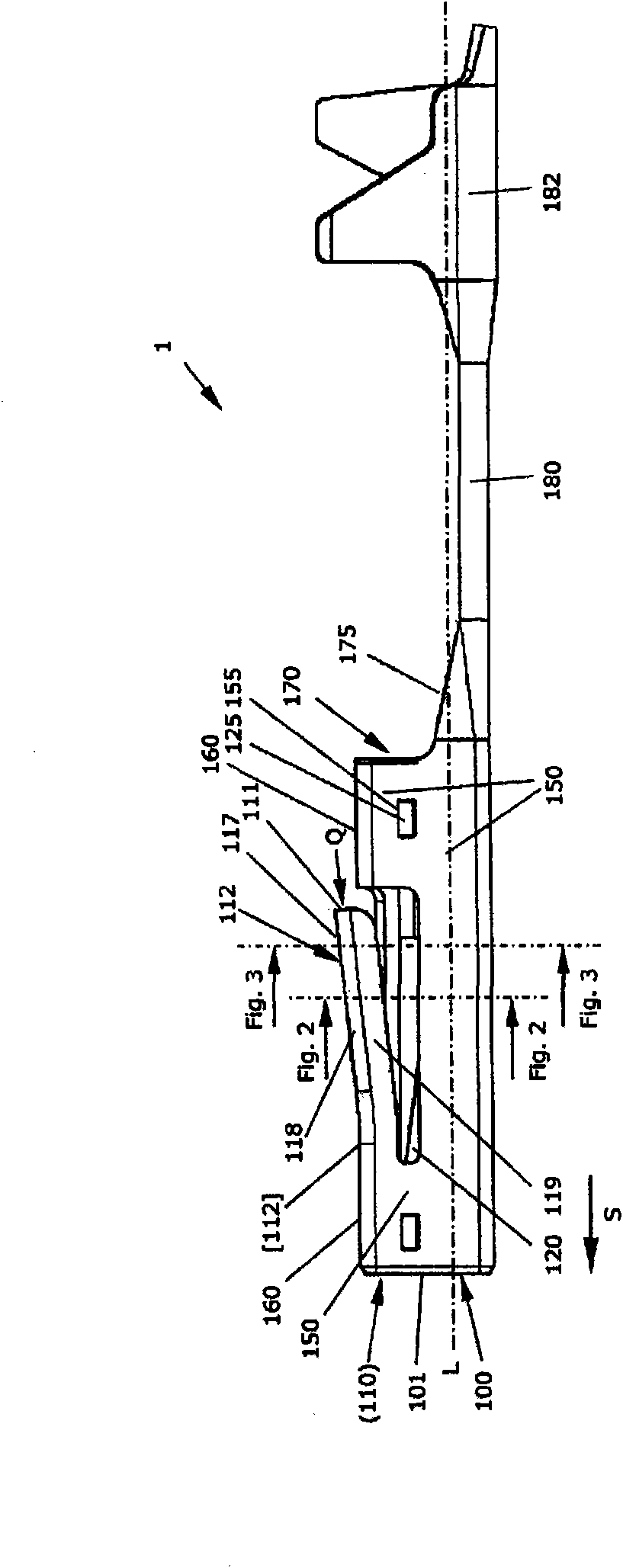

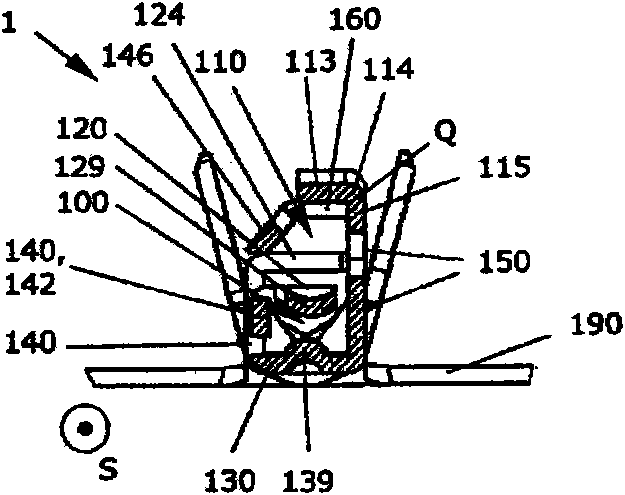

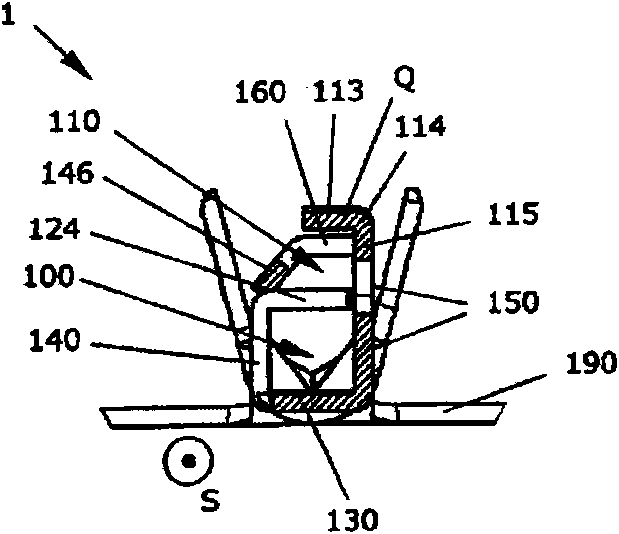

[0033] The invention is described in more detail below with reference to an electrical plug contact for an electrical plug-in connector system in the automotive sector. However, the invention is not intended to be limited to this electrical socket contact, but relates to other electrical contacts such as tab receptacle or pin electrical contacts. In principle, the invention can be used as long as the electrical contacts are locked, for example in a housing, by means of retaining springs.

[0034] The following discussion refers to the front or rear of the electrical contacts. In this case, front is intended to mean a position on the electrical contact near the free end of the contact box or near the free end of the interlock box of the electrical contact. Correspondingly, the rear part denotes a position on the plug contact arranged at a distance from the free end of the contact box or interlock box.

[0035] shown in figure 1 The electrical contact 1 according to the inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com