A low-temperature preparation of α‑al 2 o 3 coating method

A double-glow plasma infiltration and coating technology, which is applied in the direction of metal material coating process, coating, ion implantation plating, etc., can solve problems such as adverse effects on adhesion, impact on structure and performance, and substrate damage, and achieve corrosion resistance And anti-oxidation and other performance improvement, no holes, the effect of smooth and dense surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

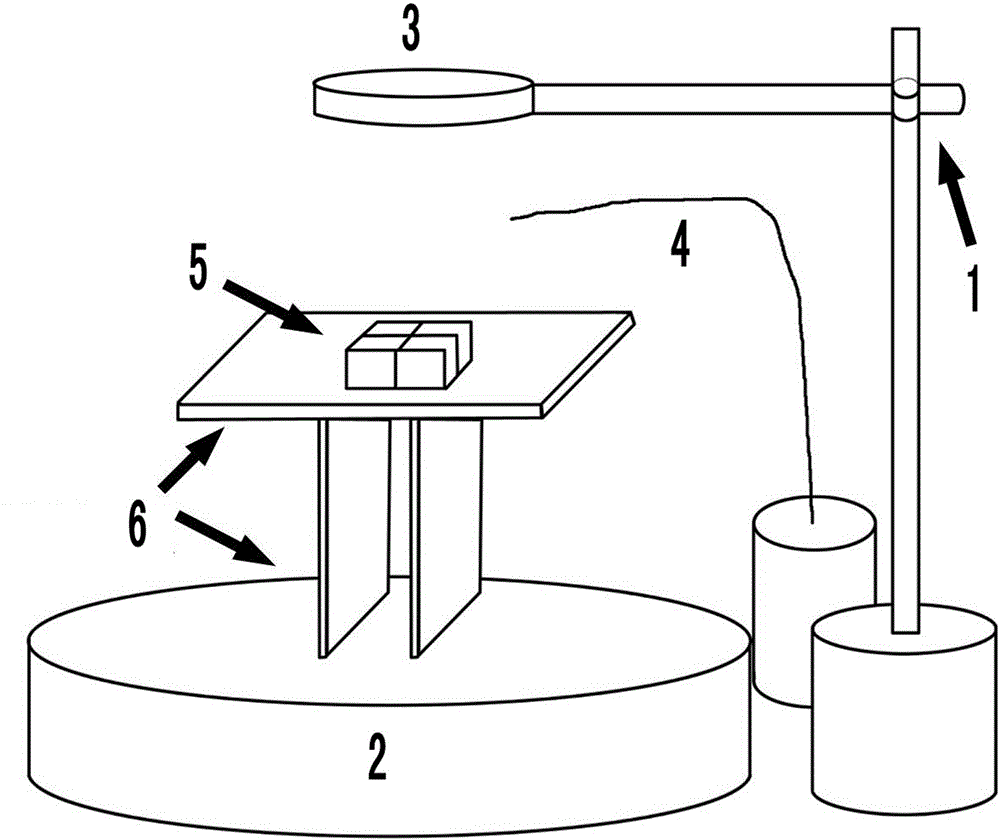

[0022] (1) 10 wt% Y, 10 wt% α-Al 2 o 3 Seed crystals and 80 wt% Al powder were uniformly ball-milled and mixed on a planetary ball mill, pressed into discs on a small cold press, and then sintered in a vacuum hot-press furnace to obtain Al / Y / α-Al 2 o 3 target;

[0023] (2) Preparation of doped α-Al on the surface of 316L stainless steel by double glow plasma metallization technology 2 o 3 Al coating of seed crystal and rare earth element Y. The experimental parameters are: vacuum degree, 2×10 -4 Pa; source voltage, -700 V, substrate voltage, -300 V, electrode spacing, 15 mm; air pressure, 30 Pa; sputtering time, 3h; sputtering temperature, 580 o C;

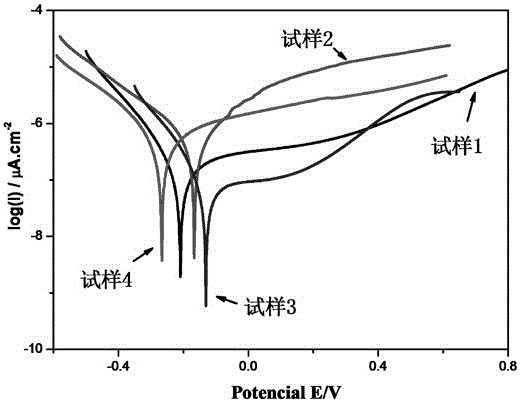

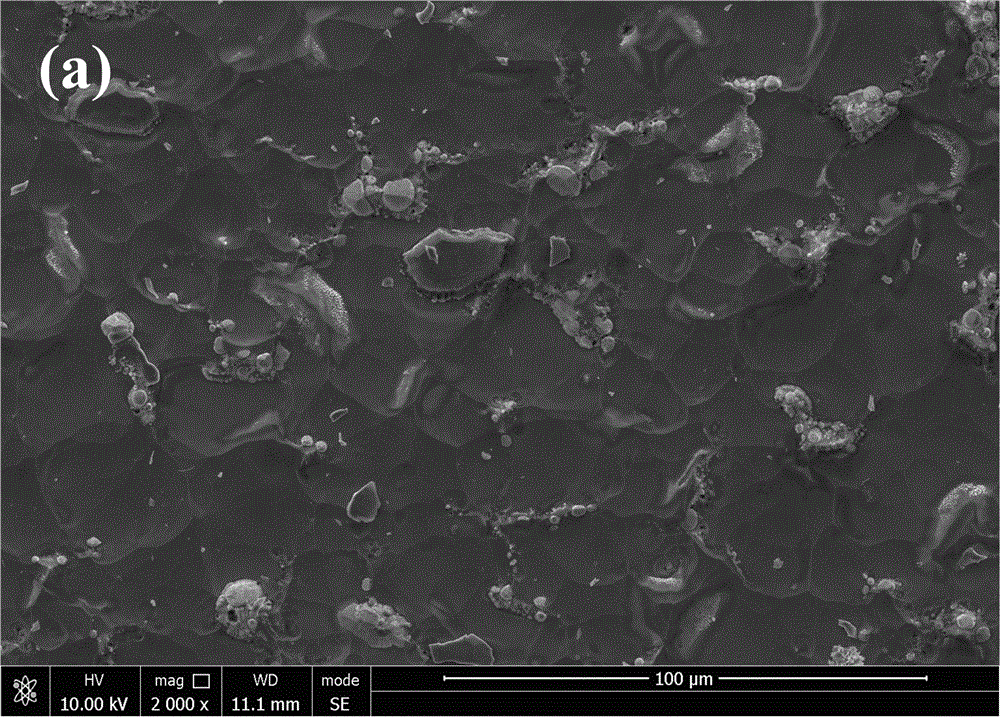

[0024] (3) Plasma oxidation is used to prepare Y and α-Al 2 o 3 The seeded co-doped Al coating is heat-treated. The oxidation temperature is 580 o C, the argon gas flow rate is 40 sccm, the air pressure is 40 Pa, and the oxidation time is 1 h. By changing the oxygen flow rate of the single factor, a coating meeting the ...

Embodiment 2

[0026] (1) 10 wt% Y, 10 wt% α-Al 2 o 3 Seed crystals and 80 wt% Al powder were uniformly ball-milled and mixed on a planetary ball mill, pressed into discs on a small cold press, and then sintered in a vacuum hot-press furnace to obtain Al / Y / α-Al 2 o 3 target;

[0027] (2) Preparation of doped α-Al on the surface of 316L stainless steel by double glow plasma metallization technology 2 o 3 Al coating of seed crystal and rare earth element Y. The experimental parameters are: vacuum degree, 2×10 -4 Pa; source voltage, -700 V, substrate voltage, -300 V, electrode spacing, 15 mm; air pressure, 30 Pa; sputtering time, 3h; sputtering temperature, 580 o C;

[0028] (3) Plasma oxidation is used to prepare Y and α-Al 2 o 3 The seeded co-doped Al coating is heat-treated. The oxidation temperature is 580 o C. The argon gas flow rate is 40 sccm, the air pressure is 40 Pa, and the oxidation time is 1 h. By changing the oxygen flow rate of the single factor, a coating meeting the ...

Embodiment 3

[0030] (1) 10 wt% Y, 10 wt% α-Al 2 o 3 Seed crystals and 80 wt% Al powder were uniformly ball-milled and mixed on a planetary ball mill, pressed into discs on a small cold press, and then sintered in a vacuum hot-press furnace to obtain Al / Y / α-Al 2 o 3 target;

[0031] (2) Preparation of doped α-Al on the surface of 316L stainless steel by double glow plasma metallization technology 2 o 3 Al coating of seed crystal and rare earth element Y. The experimental parameters are: vacuum degree, 2×10 -4 Pa; source voltage, -700 V, substrate voltage, -300 V, electrode spacing, 15 mm; air pressure, 30 Pa; sputtering time, 3h; sputtering temperature, 580 o C;

[0032] (3) Plasma oxidation is used to prepare Y and α-Al 2 o 3 The seeded co-doped Al coating is heat-treated. The oxidation temperature is 580 o C. The argon gas flow rate is 40 sccm, the air pressure is 40 Pa, and the oxidation time is 1 h. By changing the oxygen flow rate of the single factor, a coating meeting the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com