Minitype drill bit and processing method thereof

A micro-drill and micro-drill technology, which is applied in metal processing equipment, drilling/drilling equipment, boring machine/drilling machine parts, etc., can solve the problem of unbalanced drilling force, unfavorable hole position accuracy, and affecting hole position Performance and other issues, to achieve the effect of good balance, improved wear resistance, and long processing life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

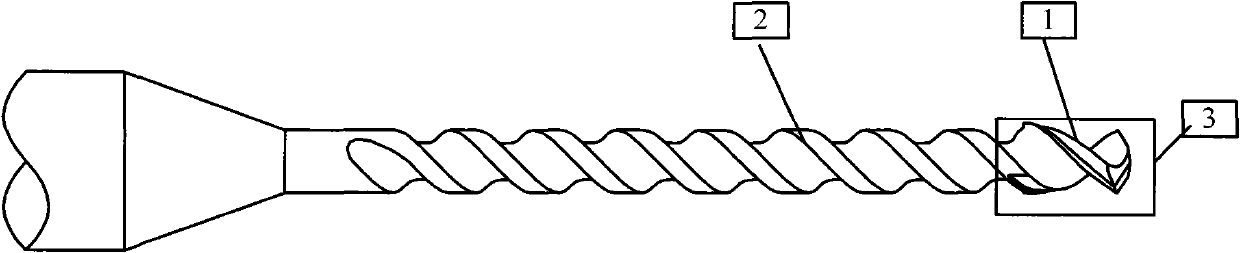

[0039] The technical solution of the present invention can be applied to micro-drills with more than double blades. Below, the micro-drills with double-blades and double grooves with a diameter of less than 6.5mm are used as an example to illustrate.

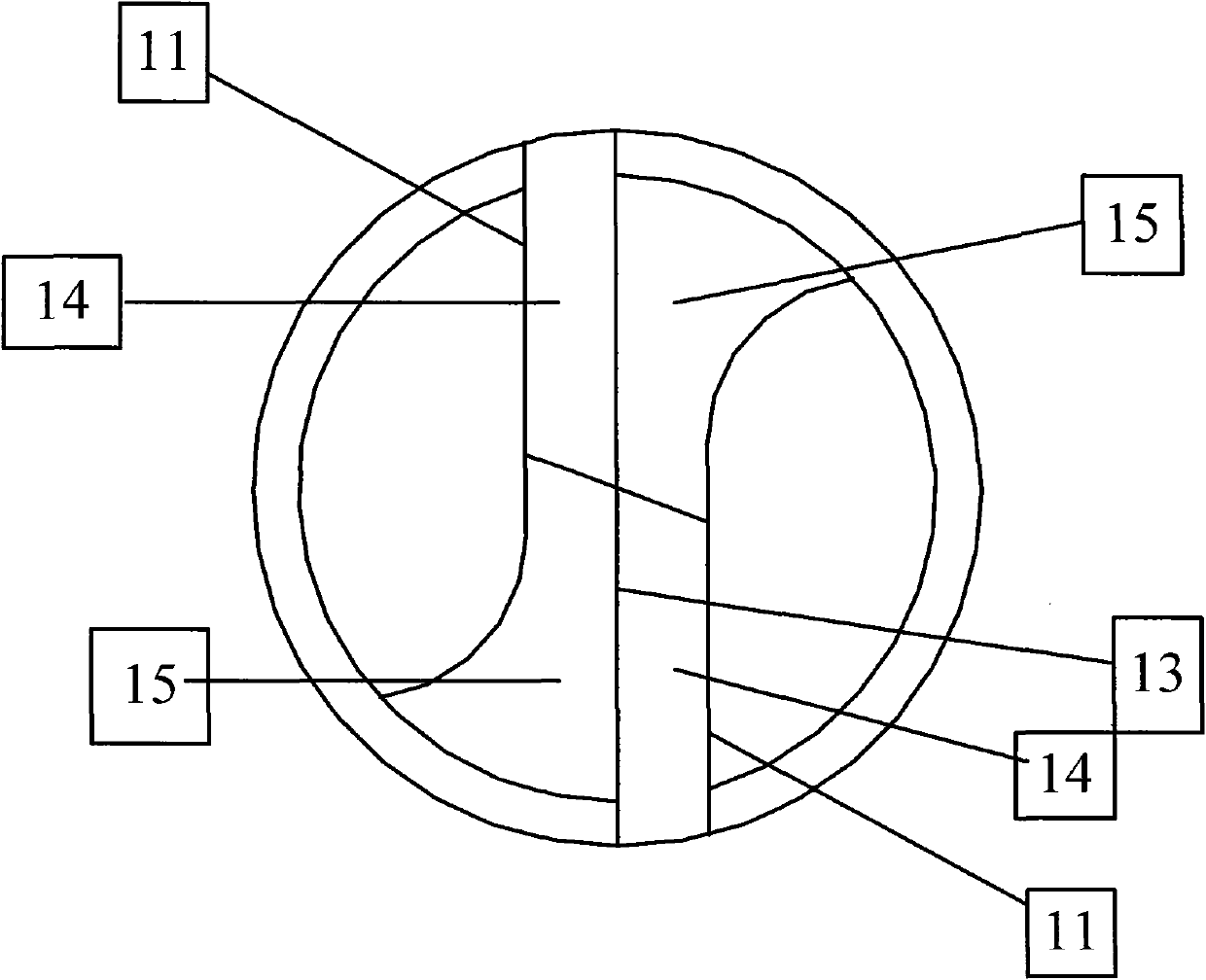

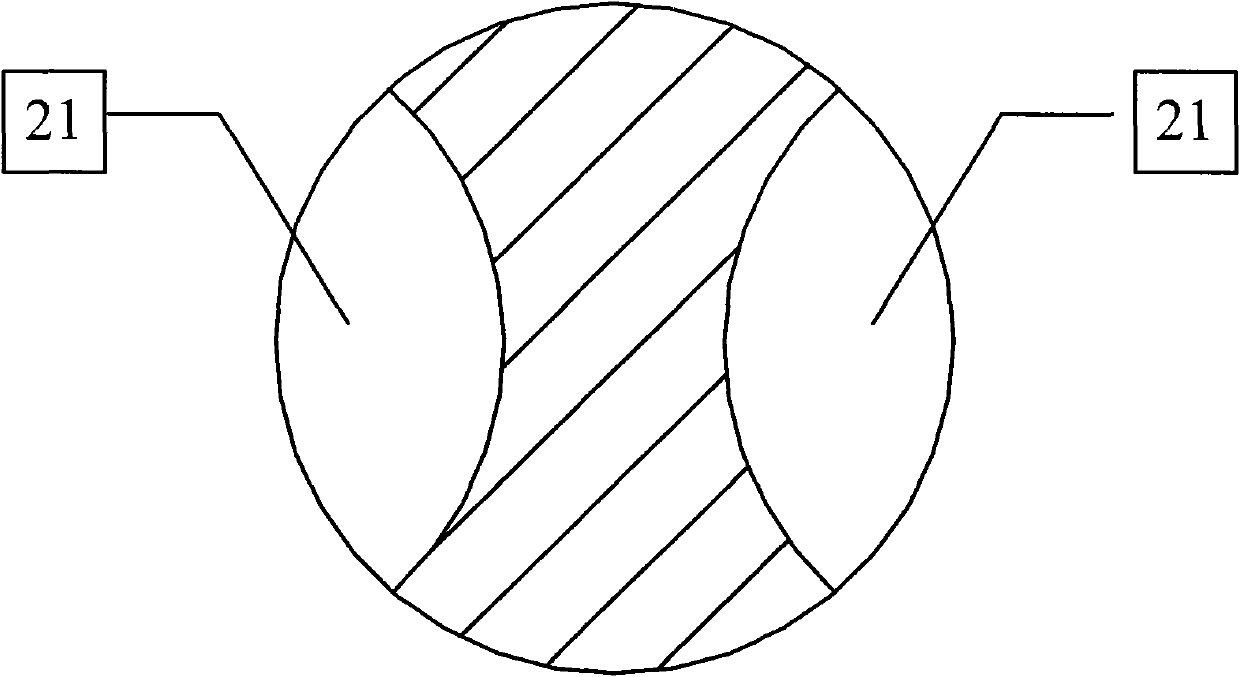

[0040] The structure of the micro-drill of described double-edged double groove is as Figure 5-11 As shown, it includes a drill tip 41 and a drill body 42, and the drill tip 41 includes two main cutting edges, two main cutter faces, and two auxiliary cutter faces (not shown in the figure) symmetrical along the axis of the micro-drill. The structure is the same as that of conventional micro drills; the drill body 42 is provided with two spirally rising chip flutes (44, 45). There are two helically rising chip flutes of the drill body, including a long chip flute 44 and a short chip flute 45, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com