Switching valve for charging and discharging food

A switching valve and filling technology, which is applied in the field of switching valves, can solve the problems of increased equipment operating costs, difficulty in achieving axial sliding, and short service life, and achieve the goals of reducing height and structural complexity, rationalizing the overall structure, and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

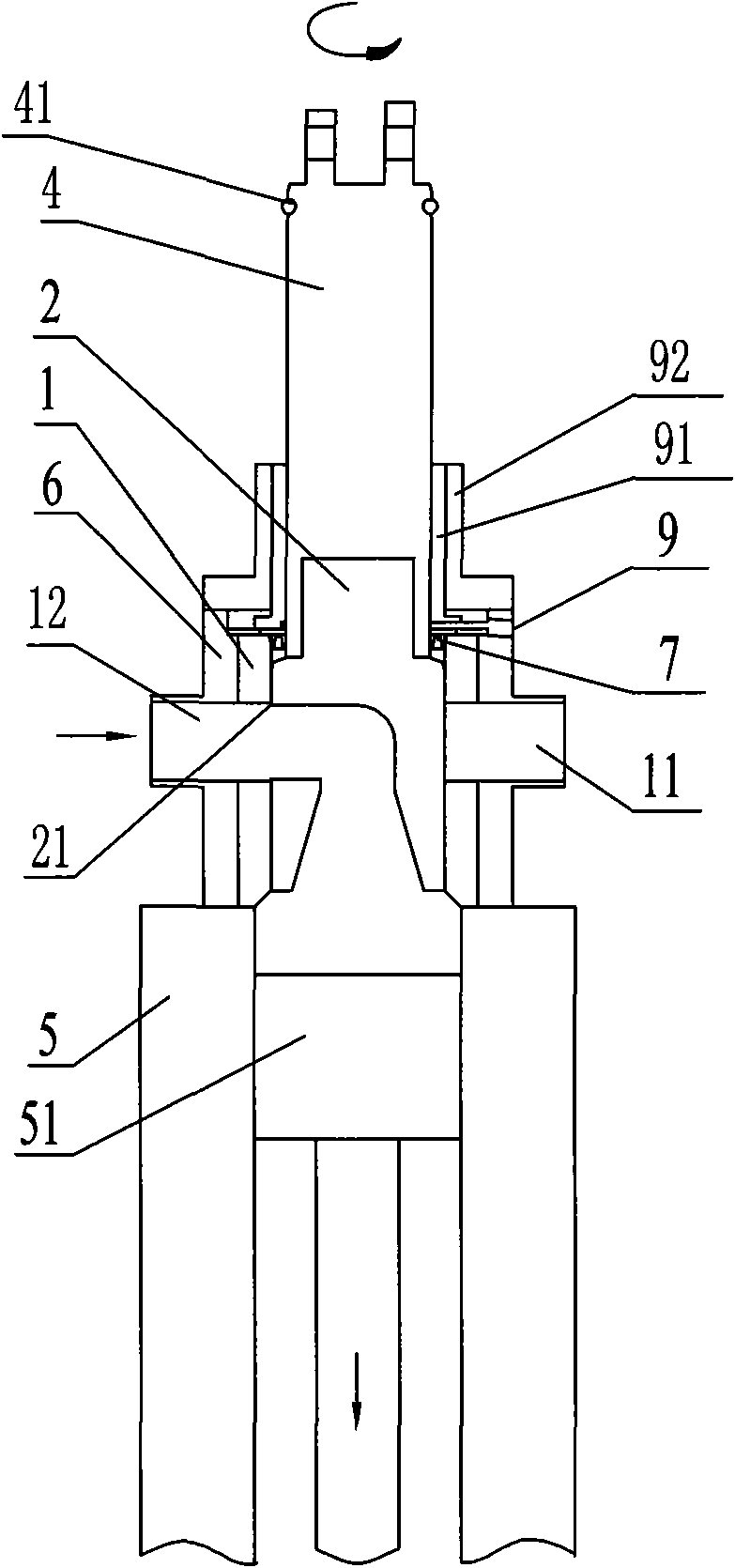

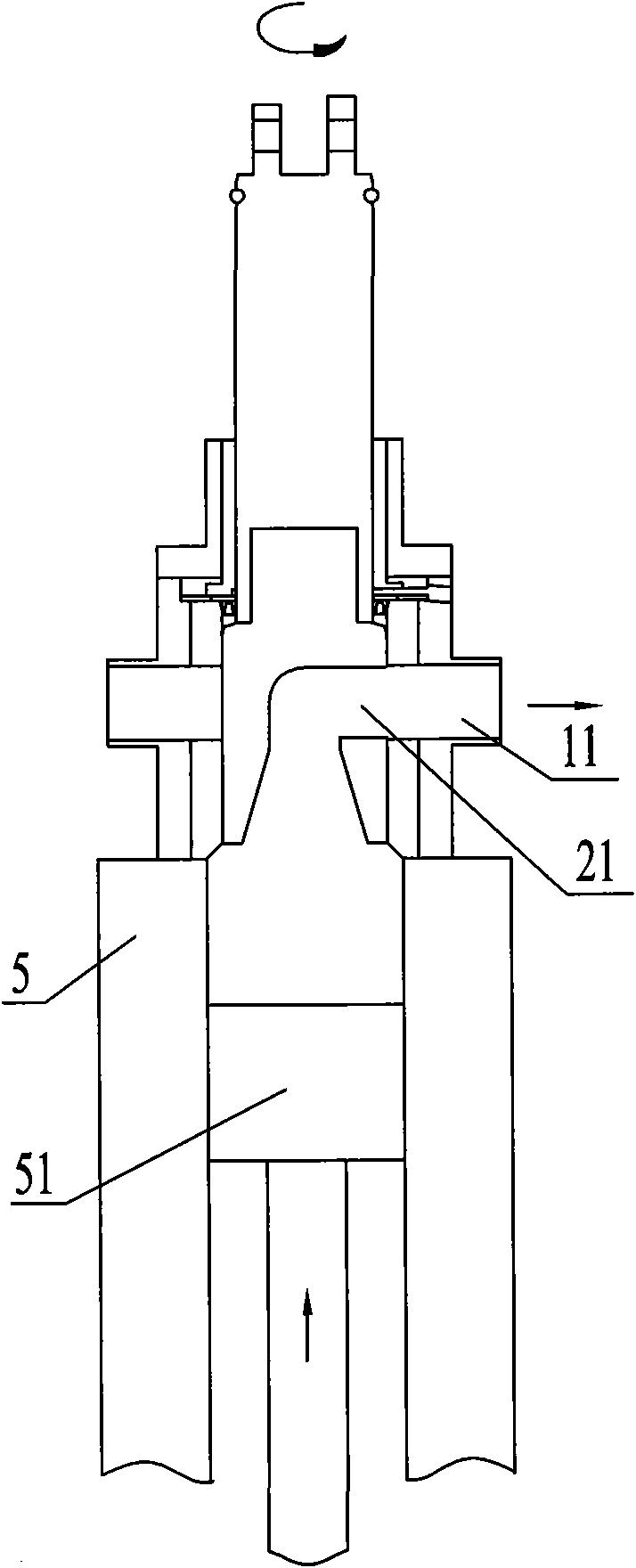

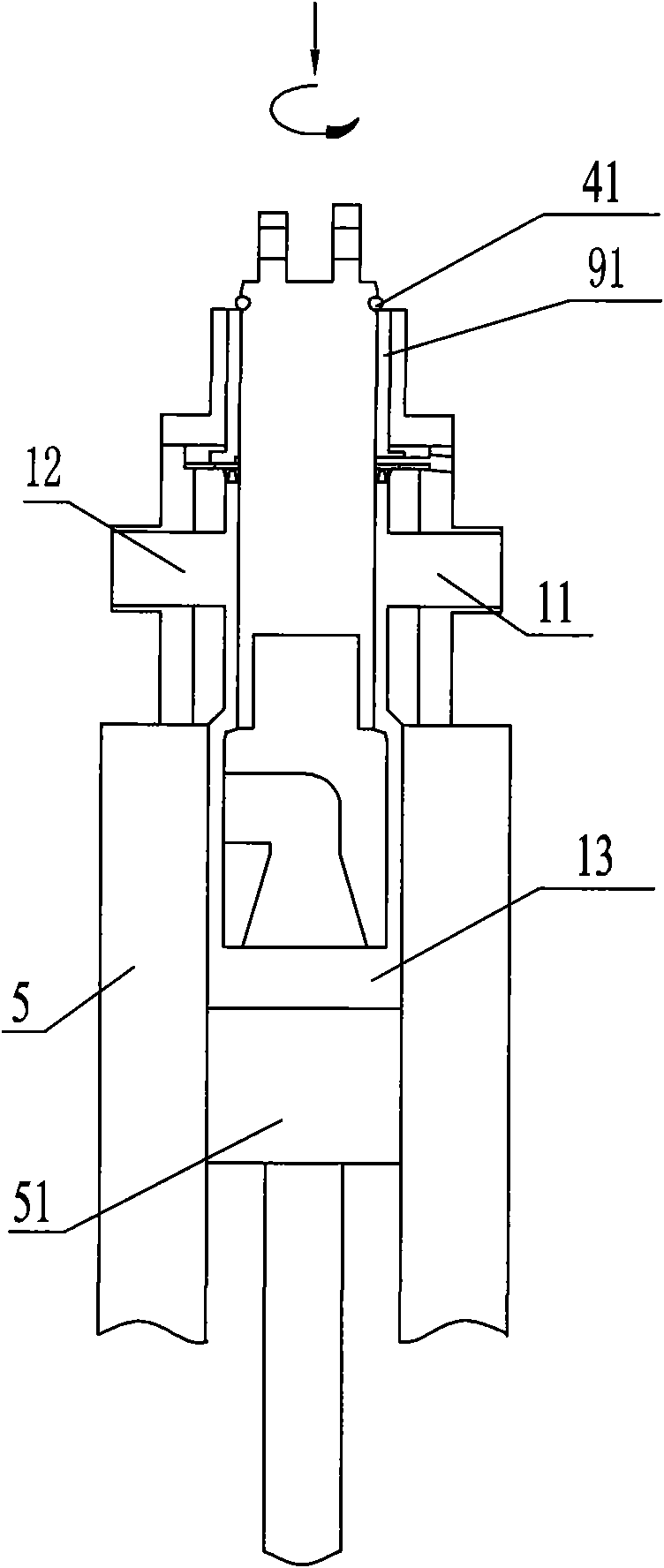

[0009] Refer to attached picture. The present invention comprises a valve body 1 and a valve core 2, on which a discharge port 11 and a feed port 12 are arranged, the valve core has a switching connection port 21 for the discharge port and the feed port, the valve body Ceramic materials are used to seal and cooperate with the valve core around the discharge port and the feed port to form a barrier to the material in the valve body. The valve core 2 and the valve body 1 can be made of ceramics, or only between the discharge port and the feed The periphery of the feed port and the valve core are sealed and fitted with ceramic materials.

[0010] The spool 2 is a rotatable and axially slidable spool, and the discharge port or the feed port is also connected to the cleaning fluid pipeline of the fully automatic cleaning-in-place system (CIP). And the cleaning cavity 13 of valve core is provided with the bottom of feeding port.

[0011] The upper end of the valve core 2 is fasten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com