Double-hob experiment table cutter system

A tool system and test bench technology, applied in the direction of testing machinability, etc., can solve the problems that cannot be repeated many times, the workpiece table cannot be rolled, and the tool adjustment is difficult. The effect of studying the pace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

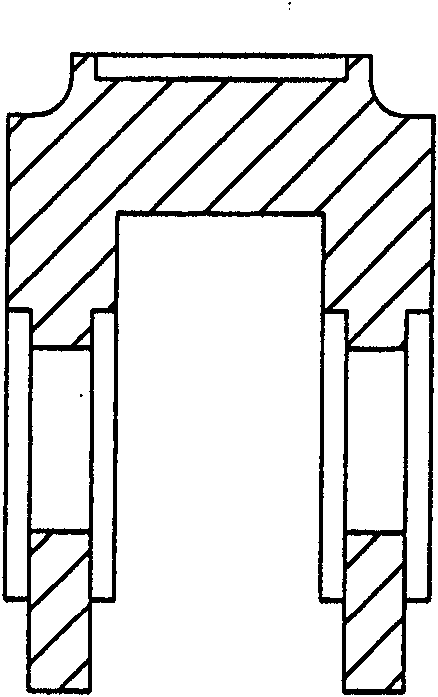

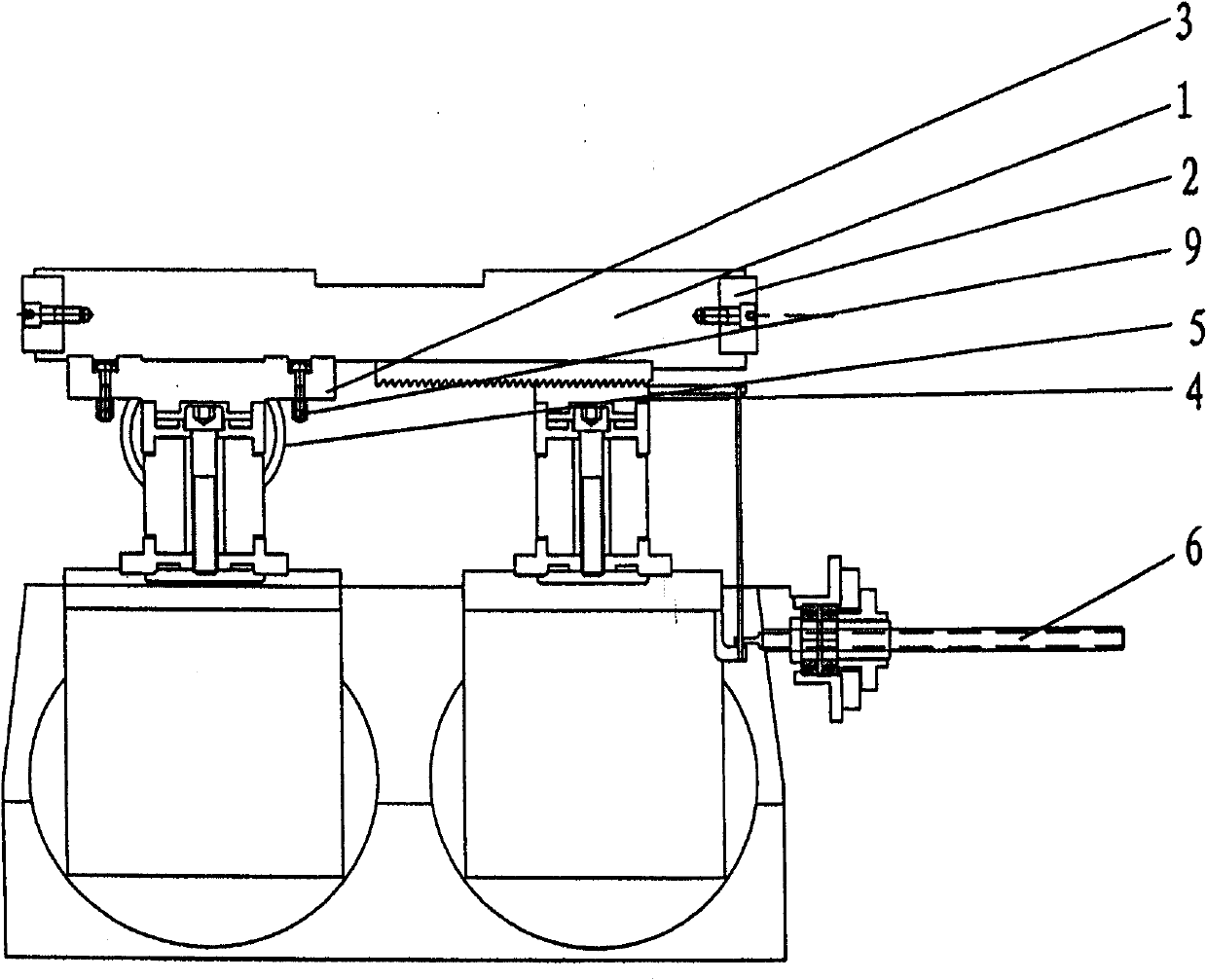

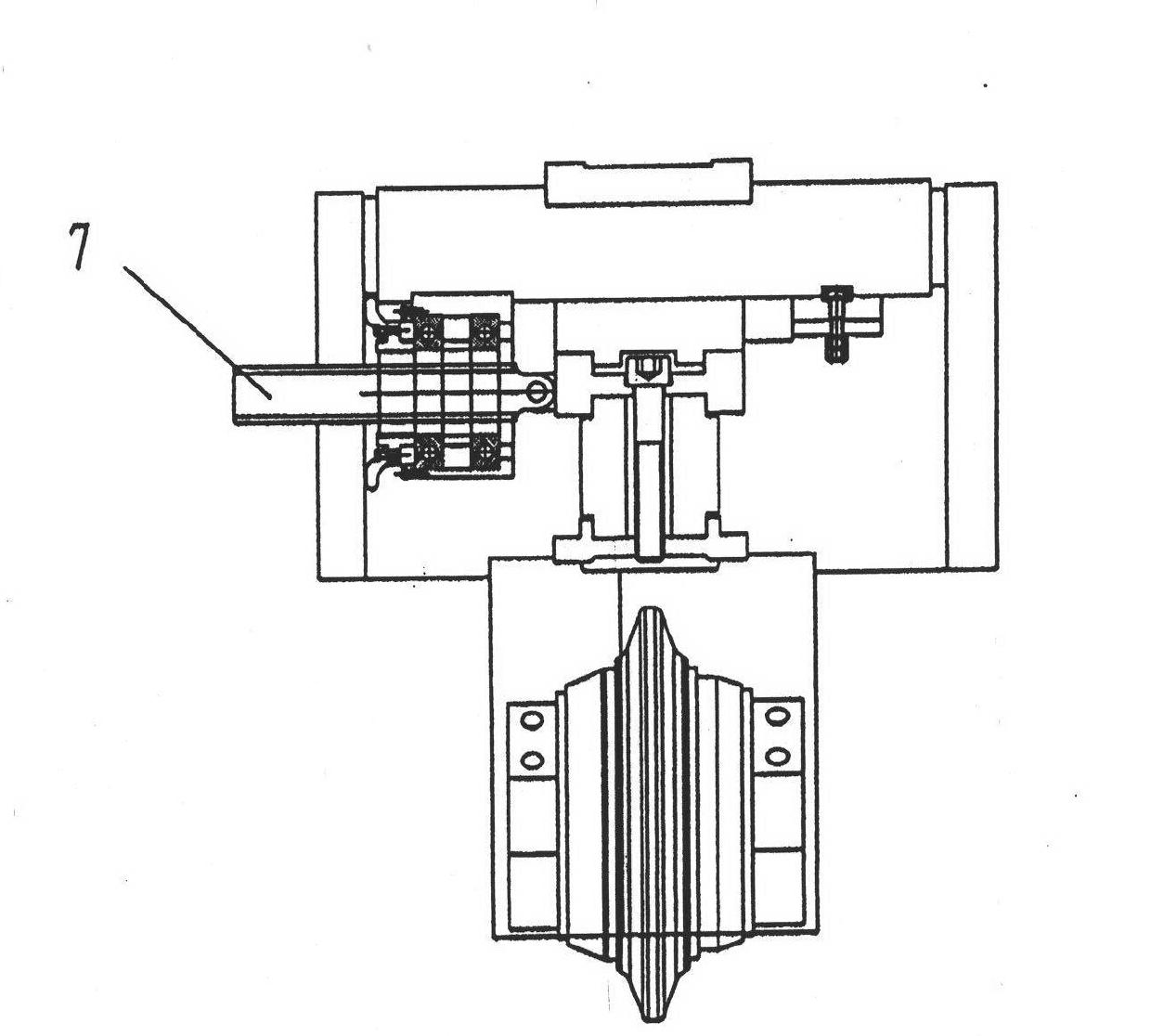

[0022] The design scheme of the present invention is that the tool system has two hobs, and each hob is installed on its own knife holder, and the knife holder is installed on the base of the cutter head, and the relative position of the two hobs is adjusted by adjusting the knife holder. The mechanism of rock breaking was studied by changing the knife spacing. The adjustment of tool penetration and rolling pressure are provided by the tool hydraulic system acting on the tool seat.

[0023] Structure of the present invention. The hob is installed on the knife holder through the flange, and the knife holder is fixed on the knife seat. The distance between the knives changes with the adjustment of the knife seat; it is connected with the tie rod of the tool hydraulic system through bolts, and the steel slide block is connected to the column on the test bench. The inlaid steel guide rail cooperates to prevent the impact of side load on the hydraulic push rod; the tool rest of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com