Container-packed coffee beverage

A coffee beverage and container packaging technology, which is applied in coffee, coffee extraction, food science, etc., can solve the problems of coffee beverage taste and aroma deterioration, long contact time between coffee beans and heated water, and decline in storage stability. Excellent aroma, excellent balance, and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] 1-1. Preparation of coffee extract, dried coffee extract and coffee extract

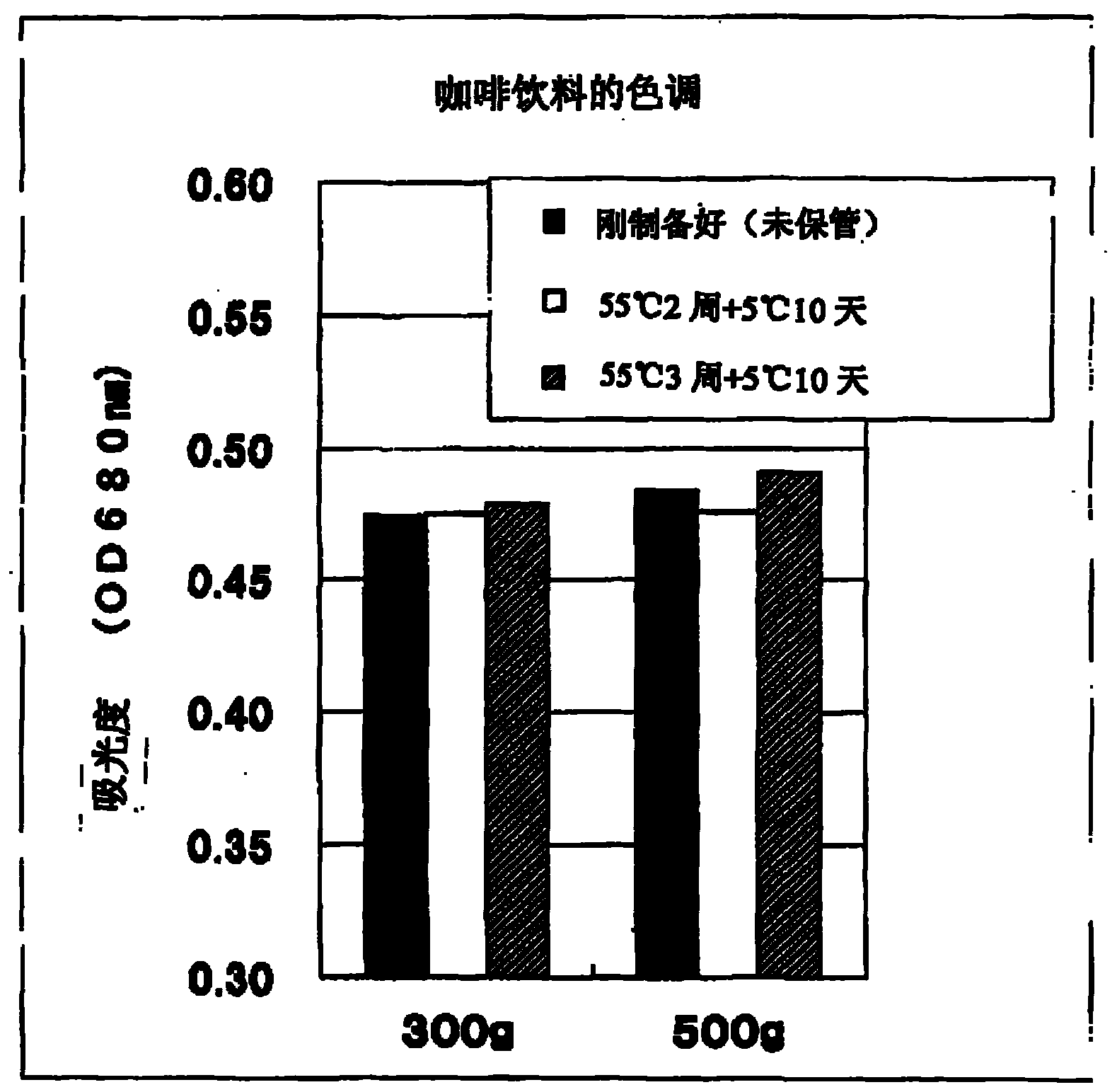

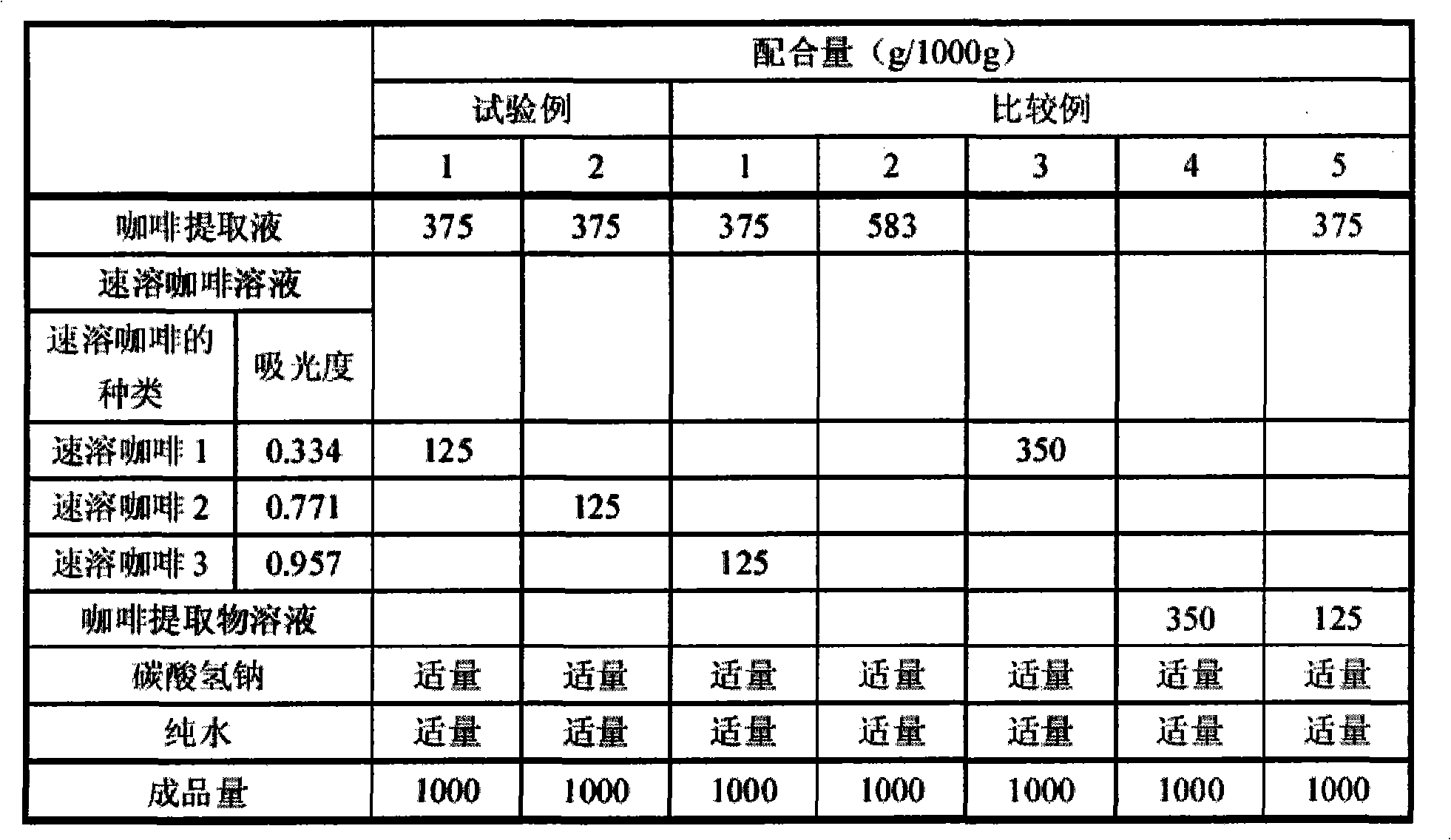

[0061] As the coffee extract, a coffee extract prepared by using a pulverizer (manufactured by Granulator Co., Ltd., Japan) to pulverize medium-roasted Brazilian coffee beans so that the particles with a particle diameter of 710 μm or more accounted for 80% or more, Warm water at 55° C. was dropped to prepare an extract of Brix 2.4, which was then filtered through a 500-mesh screen to remove insoluble solids to obtain a coffee extract.

[0062]As dry coffee extracts, three types of instant coffee were used (instant coffee 1 and instant coffee 2: coffee beans produced in Brazil were used. Extracted by continuous multi-tube extraction, concentrated, and spray-dried. Instant coffee 3: coffee beans produced in Brazil were used Coffee beans. Concentrated after extraction by continuous multi-tube extraction method, and obtained by freeze-drying), they are dissolved with 20 times the amount of hot ...

Embodiment 2

[0079] 2-1. Preparation of coffee extract and dried coffee extract

[0080] As the coffee extract, the coffee extract obtained by grinding the mixed coffee beans with a grinder (manufactured by Granulator Co., Ltd. in Japan) so that the particles with a particle diameter of 710 μm or more were 80% or more was used. It was dripped to prepare a Brix 2.0 extract, which was then filtered through a 500-mesh screen to remove insoluble solids to obtain a coffee extract.

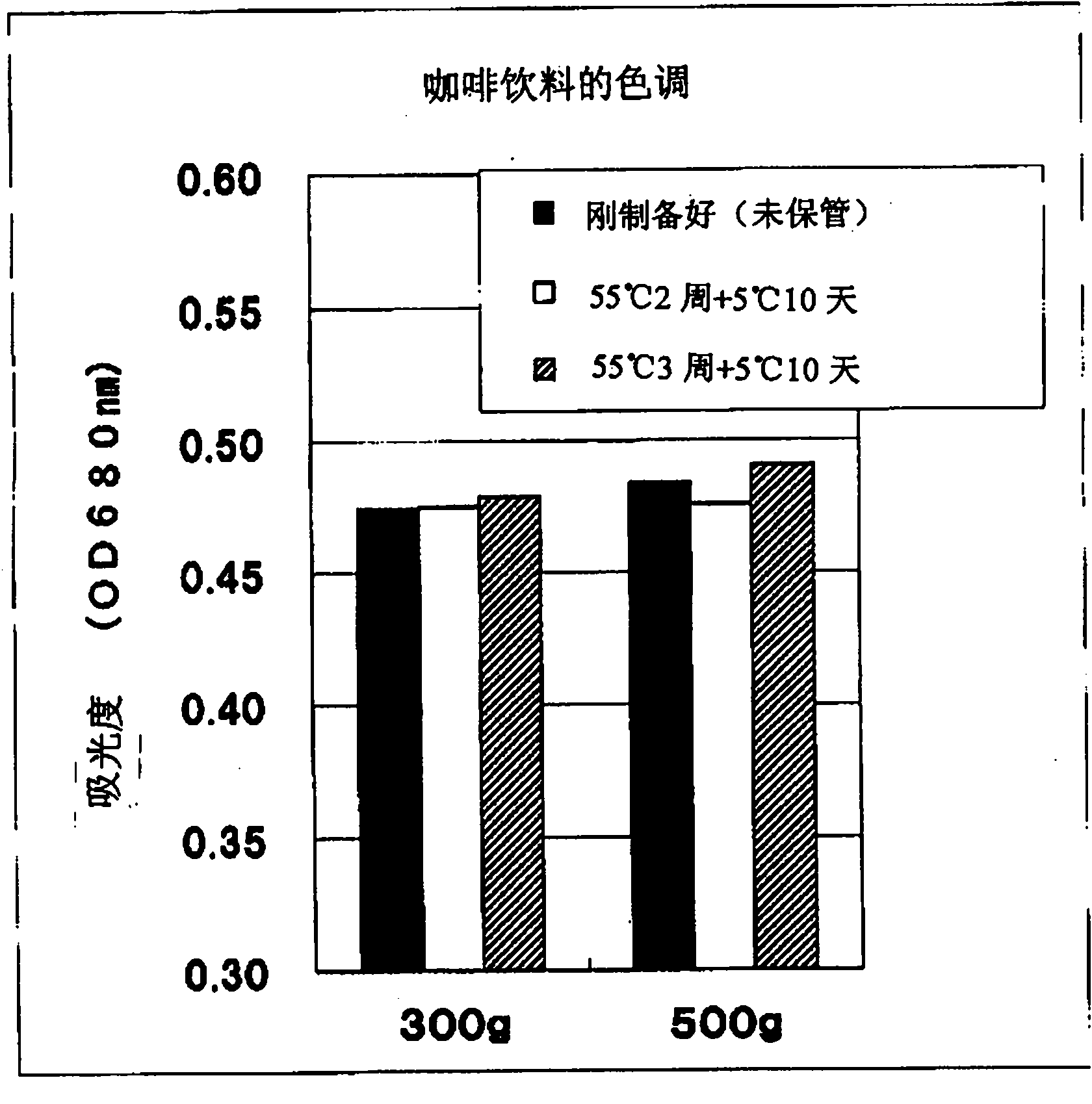

[0081] As the dry coffee extract, instant coffee whose absorbance at a wavelength of 680 nm per 1% by weight of soluble solids when diluted in water is 0.29 (Brazilian-grown coffee beans were used. Extracted by a continuous multi-tube extraction method, concentrated, and spray-dried and get). Regarding the absorbance of the dried coffee extract, in the same manner as in Example 1, the instant coffee was diluted with water to about 30 times, filtered through a 500-mesh mesh to remove insoluble components, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com