Compact dry-running piston compressor

A piston type, compressor technology, applied in the direction of liquid variable capacity machinery, mechanical equipment, variable capacity pump components, etc., can solve the problem of increasing the position requirement of the structural unit, achieve the required quantity optimization, improve the cooling effect, Efficient cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

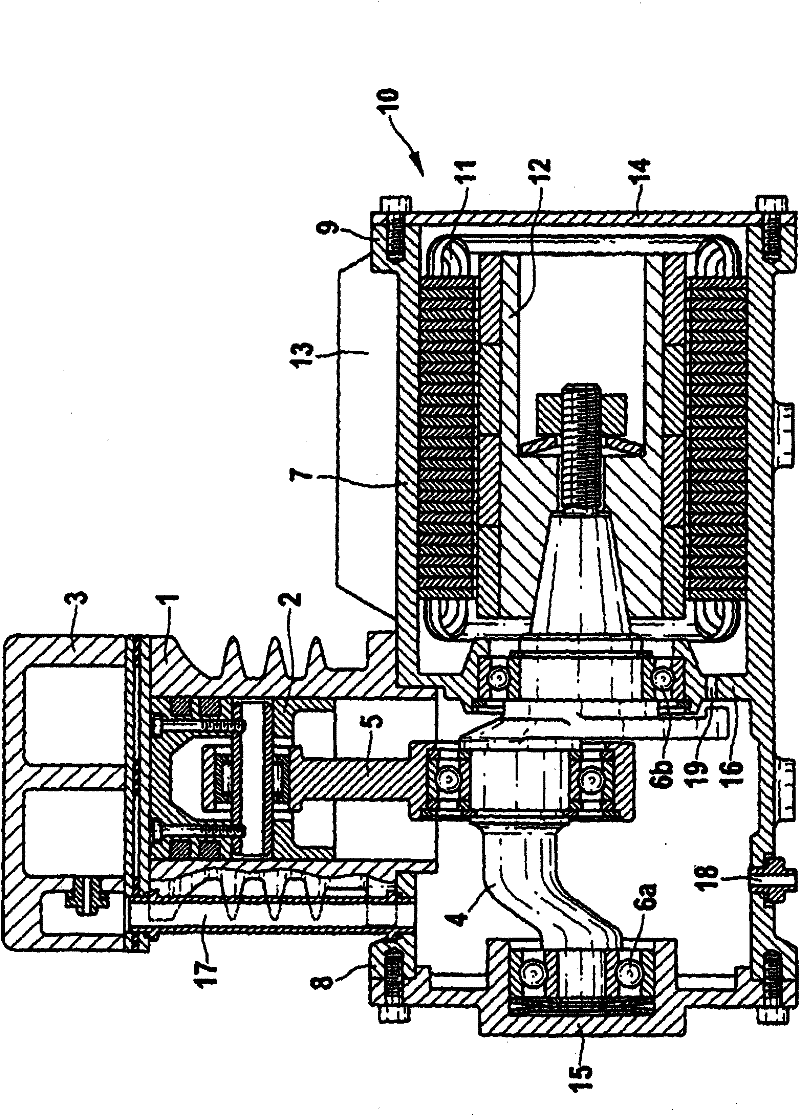

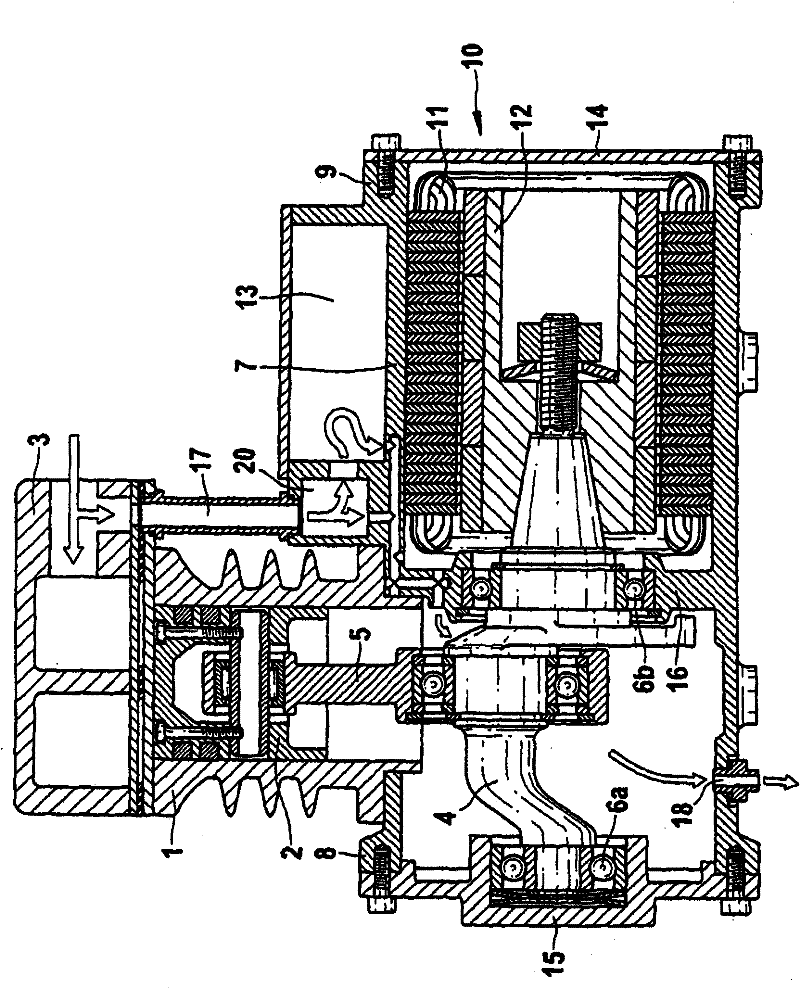

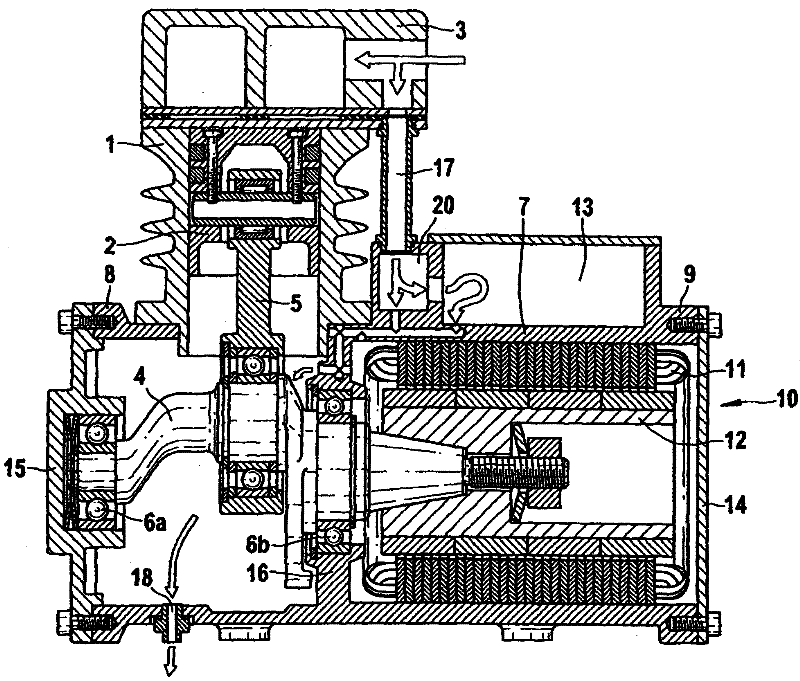

[0020] in accordance with figure 1 , the compressor has a single cylinder 1 in which a piston 2 is arranged for compressing compressed air drawn from the environment through the cylinder head 3 . The linear working movement of the piston 2 is produced by a crank drive, which essentially consists of a crankshaft 4 together with a connecting rod 5 . The crankshaft 4 is mounted rotatably relative to the compressor housing 7 via two rolling bearings 6 a and 6 b.

[0021] The compressor housing 7 consists of a first housing half 8 forming the crankcase and a second housing half 9 accommodating the electric motor 10 .

[0022] The electric motor 10 is designed as a brushless motor in this exemplary embodiment and comprises a stator 11 composed of coil windings with an iron core, which interacts with a rotor 12 equipped with permanent magnets. The rotor 12 of the electric motor 10 is screwed onto the conical end of the crankshaft 4 , which protrudes into the second housing half 9 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com