Catalytic heater

A catalytic converter and heating system technology, applied in the field of catalytic heating systems, can solve the problems of limited practicality of batteries, and achieve the effect of catalytic ignition and high-efficiency catalytic ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

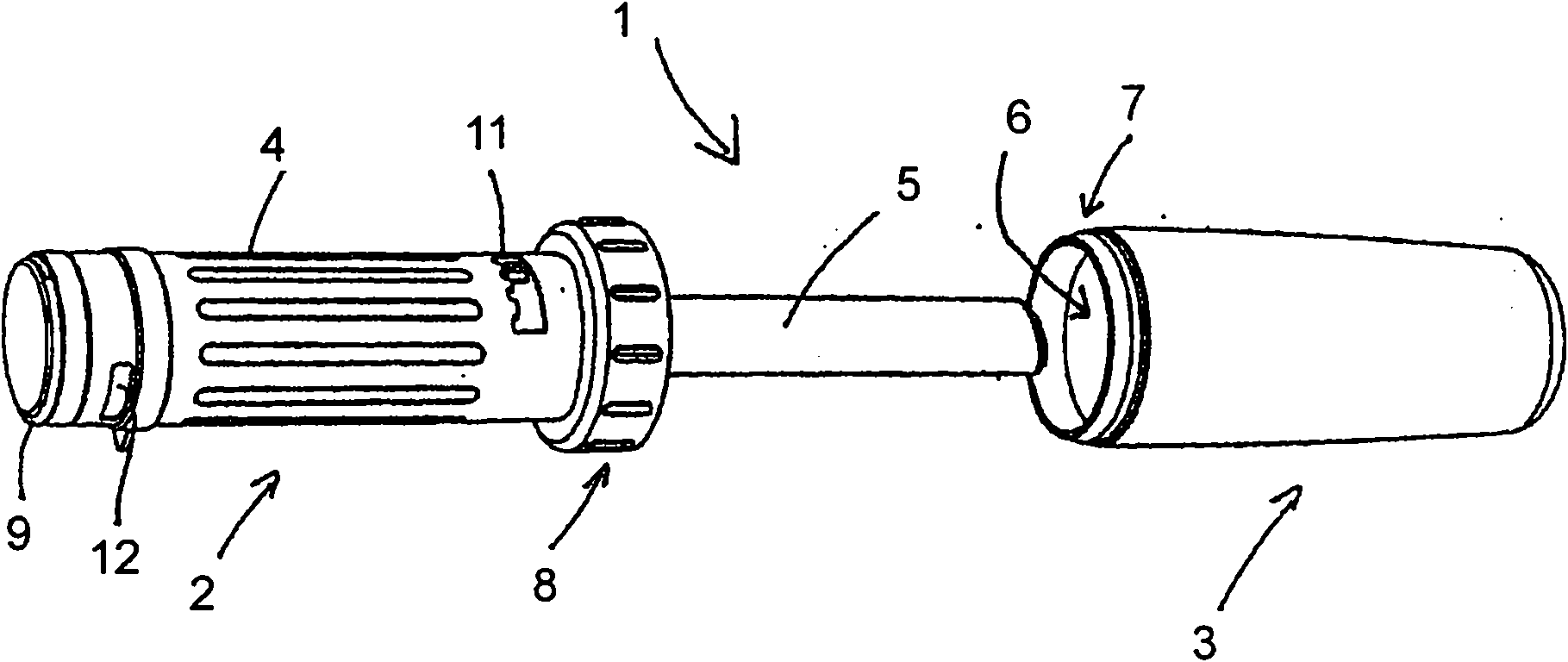

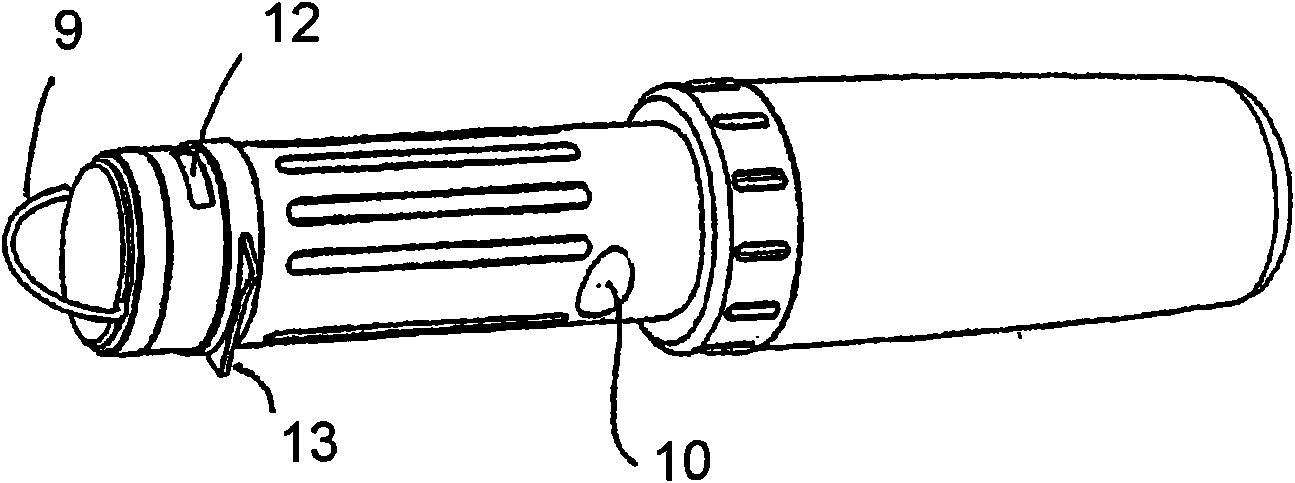

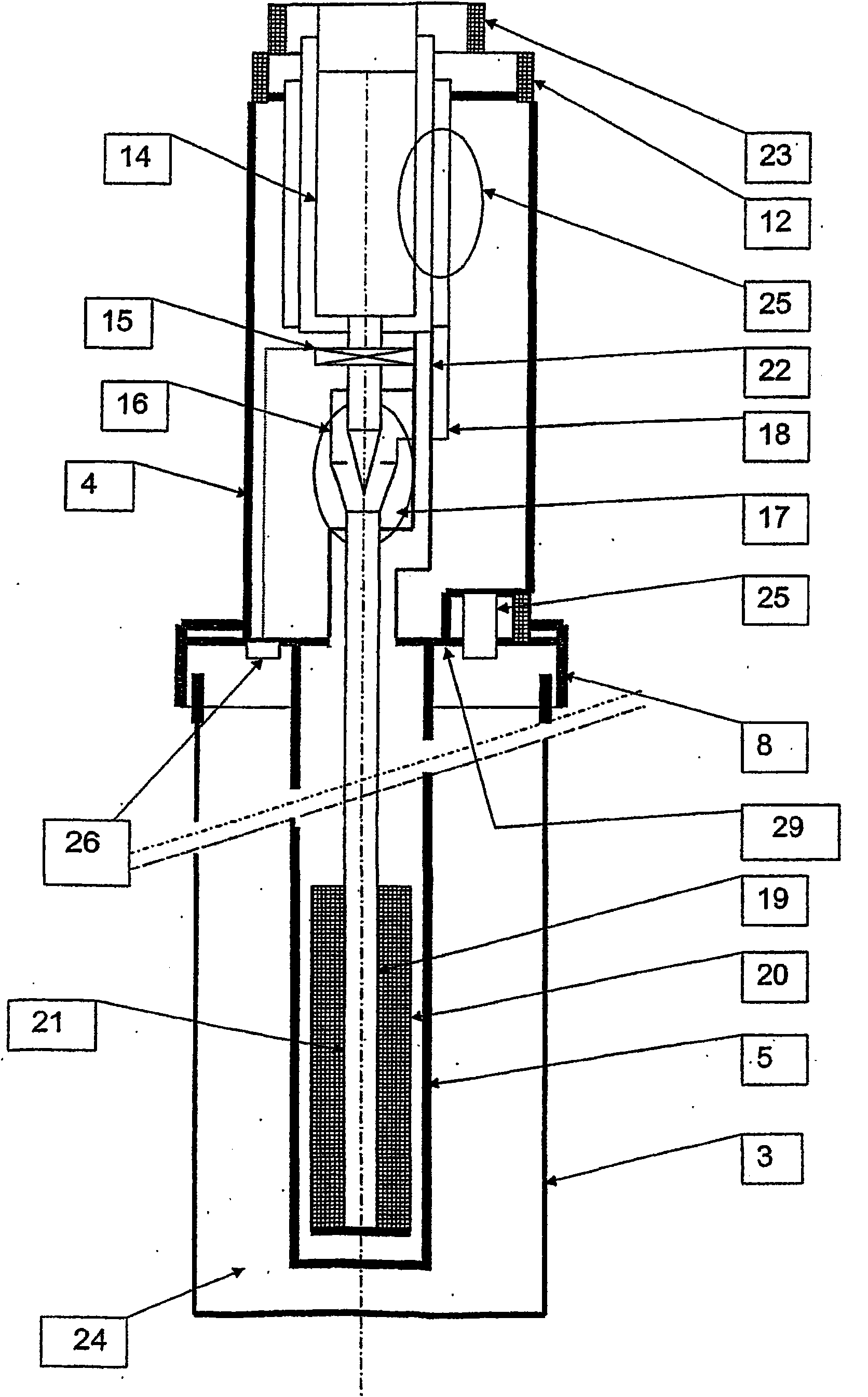

[0101] Figure 1 shows a heating system 1 according to the invention. The heating system 1 includes a heating unit 2 and a protective container 163 . The heating unit 2 has a handle 4 for connecting the heating unit 2 and a heating tube 5 which can emit heat radiation from a catalytic element housed in the heating tube 5 . When the heating system is not in use, the heating tube 5 may be fitted in the protective container 163 . The container 163 can also be used to store fluid or other materials related to heating with the heating tube 5 such as powder, or to form a storage container for fluid or other materials during transportation and use. The container 163 can be used for hot fluid and function as an insulated bottle, or to warm hands by holding the container 163 . To reduce the energy output to the environment, the container 163 may be insulated.

[0102] The container 163 has an upper opening 6 and a thread 7 corresponding to an internal thread (not shown) of the adapter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com