Separation device of plastic particles and dust by negative-pressure air power

A technology of plastic particles and separation device, applied in the field of sorting machines, can solve the problems of low production efficiency, endangering the health of operators, and harsh working environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

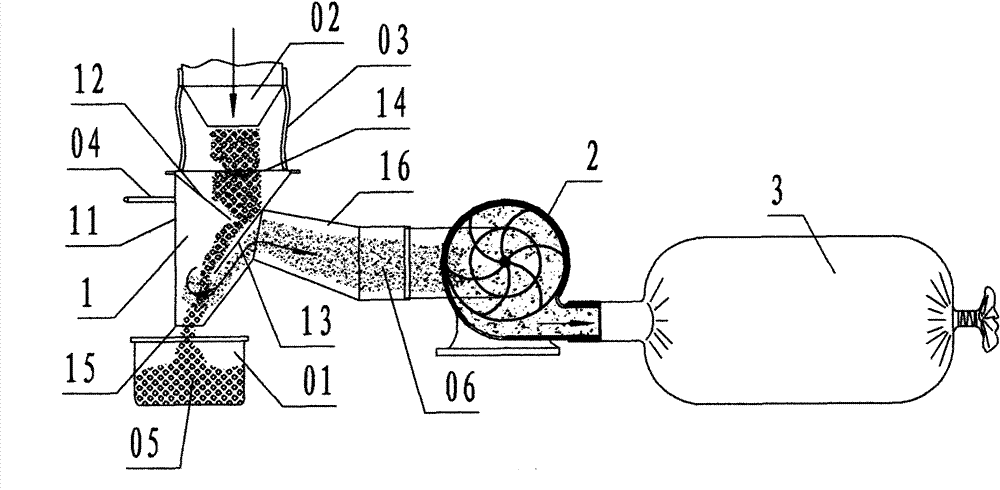

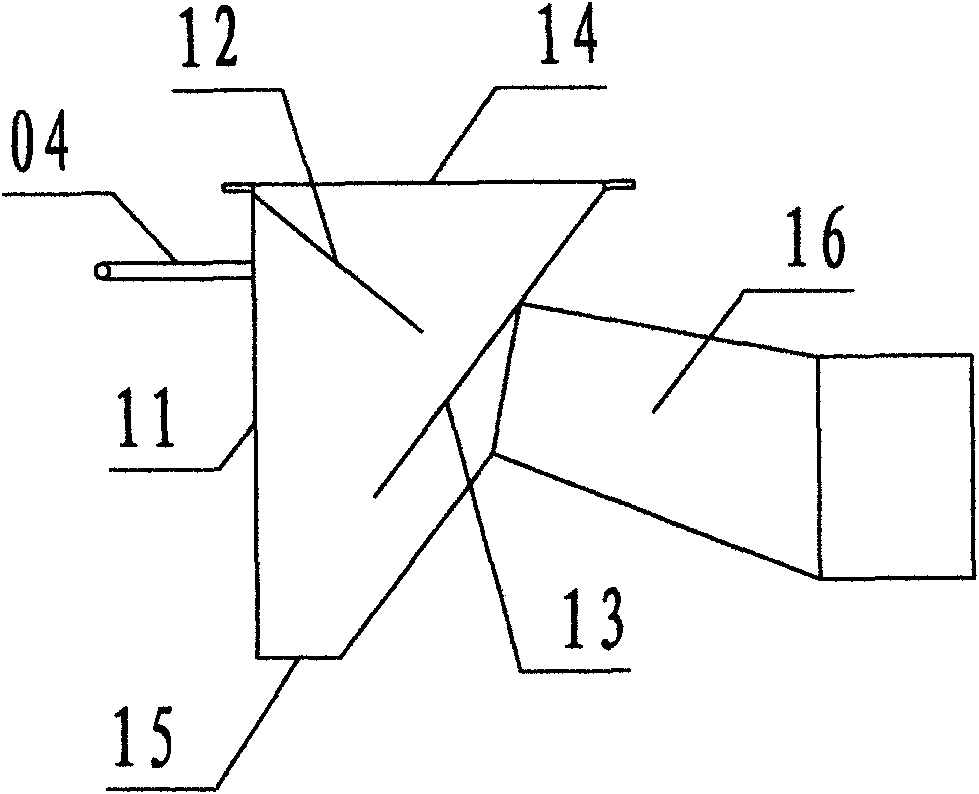

[0015] refer to Figure 1 ~ Figure 2 , a device for separating plastic particles and dust under negative pressure wind power of the present invention, comprising a separator 1, an induced draft fan 2, and a dust bag 3, wherein: the separator 1 is composed of a housing 11, an upper guide plate 12, a lower The guide plate 13, the mixing inlet 14, the particle outlet 15, and the dust air duct 16 are composed; wherein, the housing 11 is made of stainless steel plate, connected up and down, a rectangular funnel-shaped thin wall box; the upper edge of the housing 11 It is a mixing inlet 14 that is viewed as a rectangle from above, the lower edge is a rectangle viewed from above, and the particle outlet 15 that is closed from right to left on the side; in the inner cavity of the housing 11: from the upper left edge to the center of the inner cavity, there are welded An upper guide plate 12 composed of a stainless steel plate with a downward slope of 40° to the upper edge; from the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com