Solar battery module and preparation process thereof

A technology for solar cells and manufacturing processes, applied in electrical components, sustainable manufacturing/processing, circuits, etc., can solve the problems of inconsistent appearance and shape of laminated components, different sizes of right-angle sheets and chamfered sheets, and increased difficulty for users. Achieve the effect of facilitating large-scale industrialization, facilitating large-scale application, and reducing power generation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

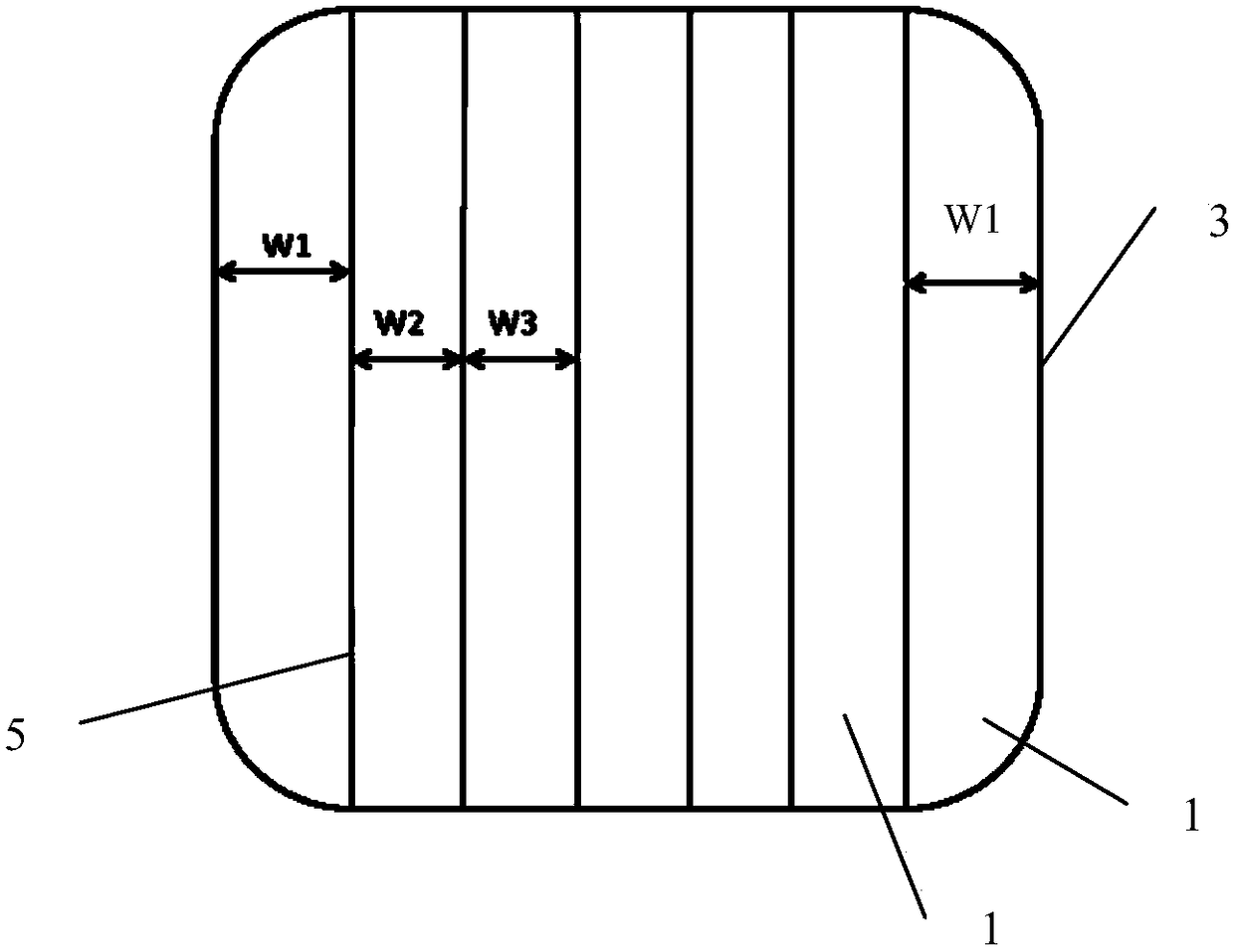

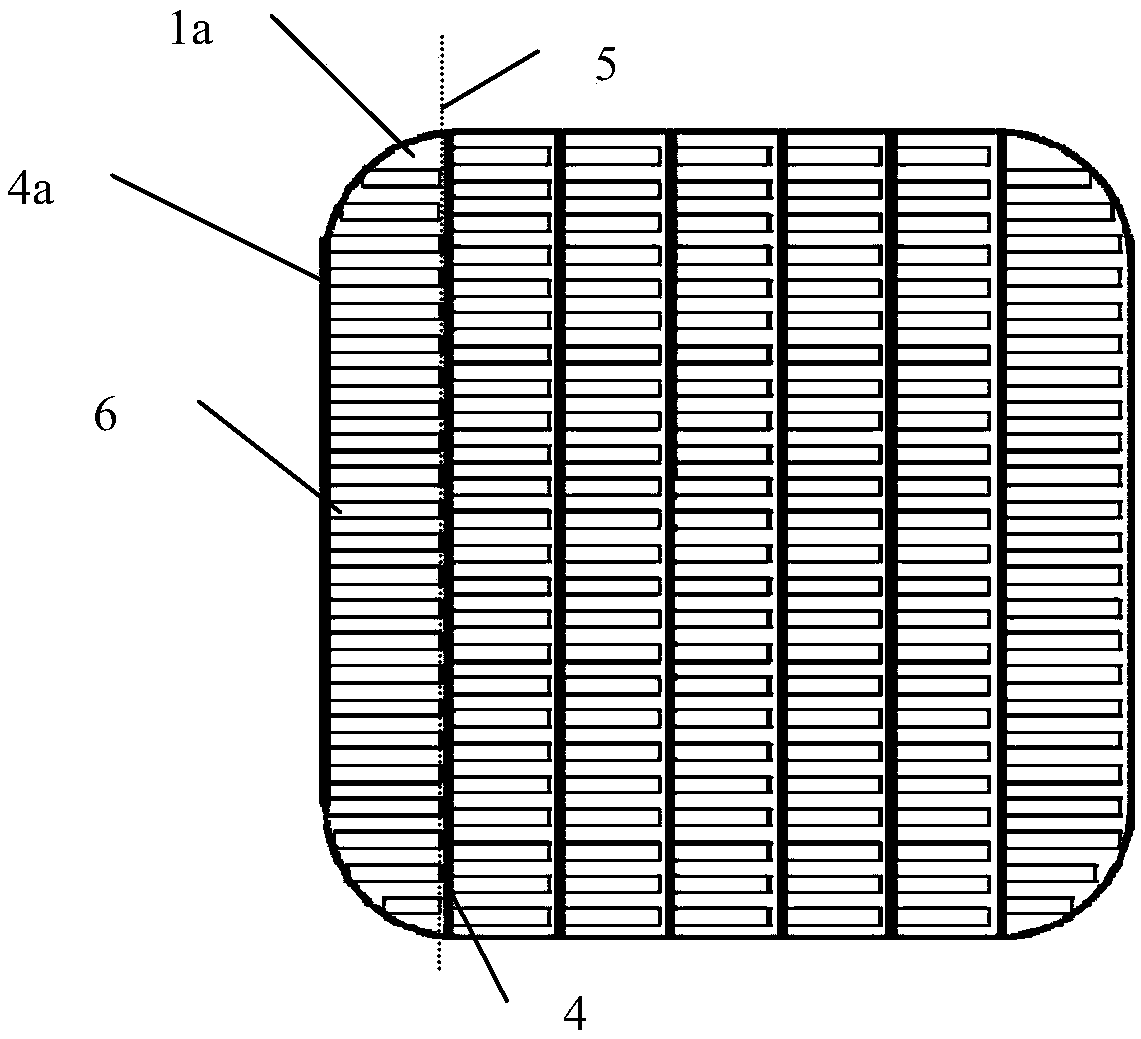

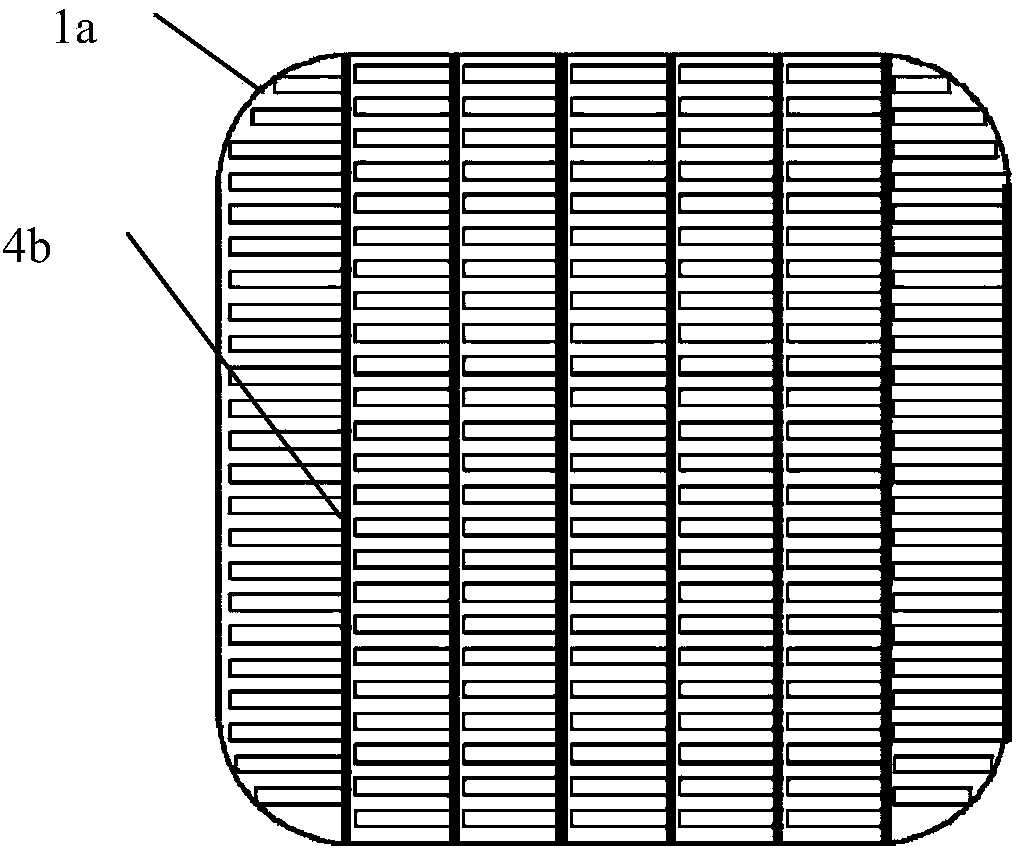

[0038] Such as Figure 1-7 As shown, it is a solar cell module of the present invention, which includes panels, encapsulation materials, battery strings, encapsulation materials and back sheets arranged in sequence from top to bottom, wherein the panel is a glass plate, the encapsulation material is POE, and the back sheet is the back Partially transparent glass panels. The battery string 2 is mainly composed of several small battery pieces 1 connected in series, and the small battery piece 1 is divided into non-right-angle battery pieces 3, that is, after multiple divisions in the horizontal direction along the longitudinal non-deposited metal parts of the non-right-angle battery pieces 3 Each narrow sheet-shaped small battery sheet 1 is formed, and the area of each small battery sheet 1 is equal. The corners of one side of the small battery sheet located at the beginning and end of the non-right-angled battery sheet 3 are chamfered, and the corners of the small battery she...

Embodiment 2

[0048] The difference between this embodiment and Embodiment 1 is that this embodiment uses P-type back passivated cells to make solar cell modules, and the P-type back passivated cells are single-sided power generation cells, and the back is covered with aluminum paste and silver paste. There is basically no power generation under the covered light. The positive and negative electrodes of the battery are distributed on the front and back of the battery. The front and back of the battery are respectively equipped with 3 to 9 busbars. The front and back busbars of the battery are not on the battery. At the corresponding positions up and down, when the P-type back passivated cell is cut into small cells 1, the front busbar on each small cell 1 is on the front side, and the back busbar is on the back side. The other side.

[0049] The manufacturing steps of the solar cell module are as follows:

[0050] (1) Select the target cell: select the P-type back passivated cell. When sor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com