Full fiber ceramic body glue discharging method and kiln

A technology of ceramic body and full fiber, which is applied in the debinding method of full-fiber ceramic body and the field of kiln, which can solve the problems of high cost, unstable performance of the green body, slow debinding speed, etc. Good glue effect and fast glue removal speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below by embodiment, in conjunction with accompanying drawing, technical scheme of the present invention is described further:

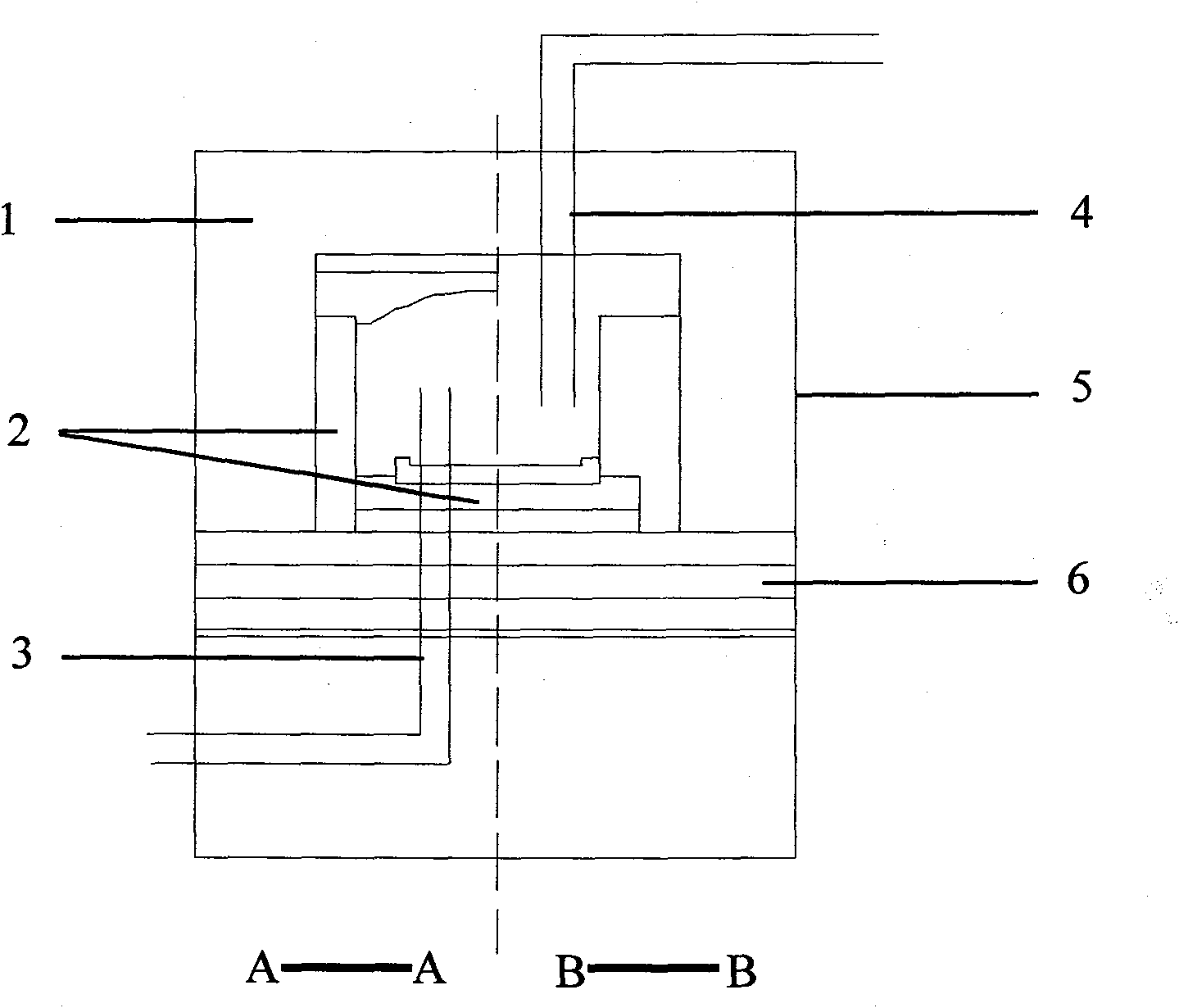

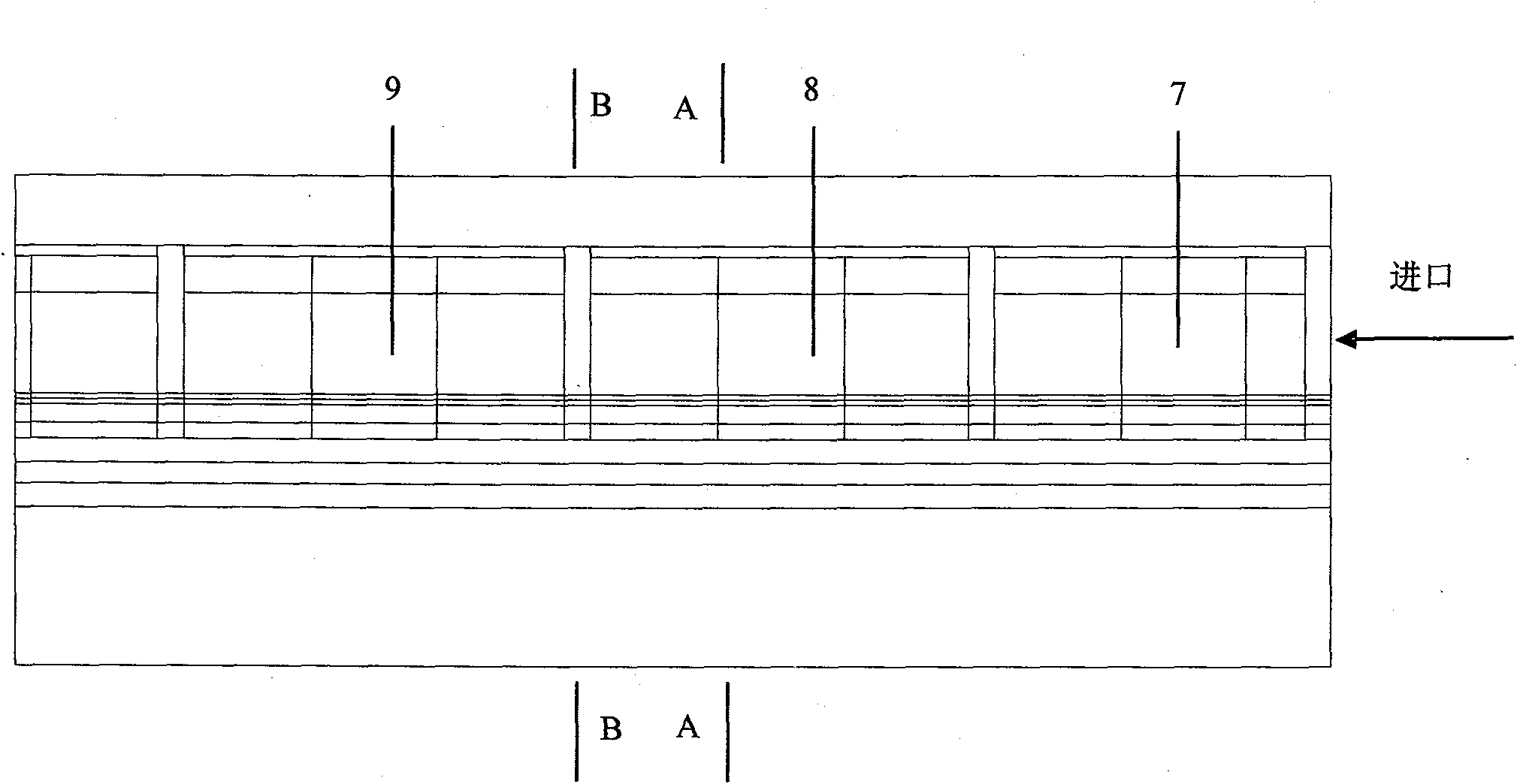

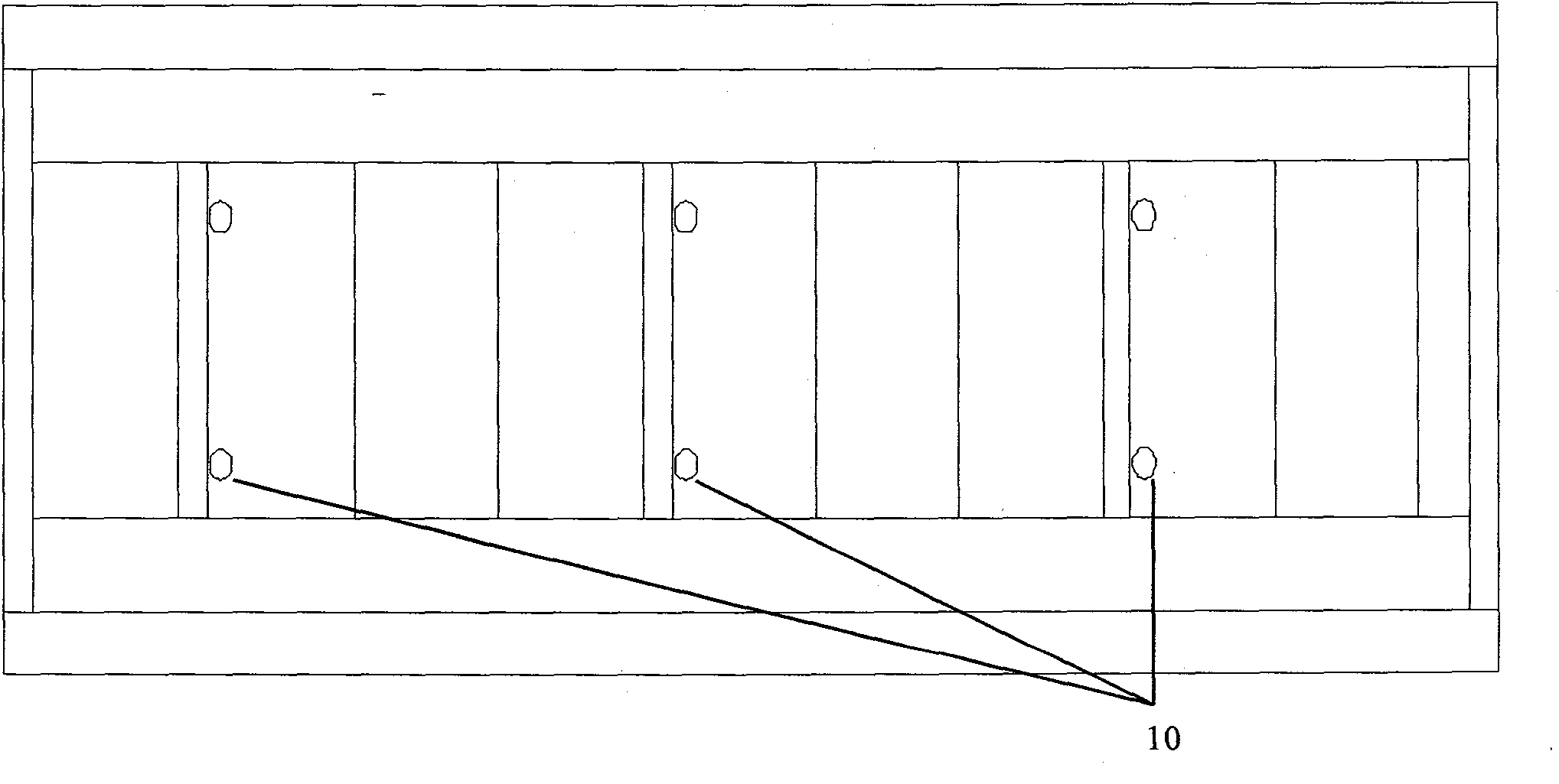

[0020] Implementation example: eg figure 1 , 2 , 3, 4, and 5 show a method for debinding a full-fiber ceramic body. The ceramic green body containing organic matter is heated in a full-fiber ceramic body debinding kiln, and then heated for three times. The organic matter in the green body turns into gas and is discharged, so that the green body forms a porous green body with a certain strength and a dense structure, and at the same time keeps the shape of the green body without obvious bending deformation, so that the green body can form a dense body with a complete shape during the firing process, improving Product yield. The holding temperature for debinding can be 600-1000°C.

[0021] A full-fiber ceramic body debinding kiln implementing the above method mainly includes a kiln body, a heating element, an internal structure, refractory ma...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap