Gear transmission device

A technology of gear transmission and gears, which is applied in gear transmissions, transmissions, belts/chains/gears, etc., can solve the problems of temporary solutions, increased gear manufacturing costs, and the inability to overcome the increase in inter-tooth gaps, so as to improve transmission Accuracy, convenient adjustment and precision control, effect of relaxing precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

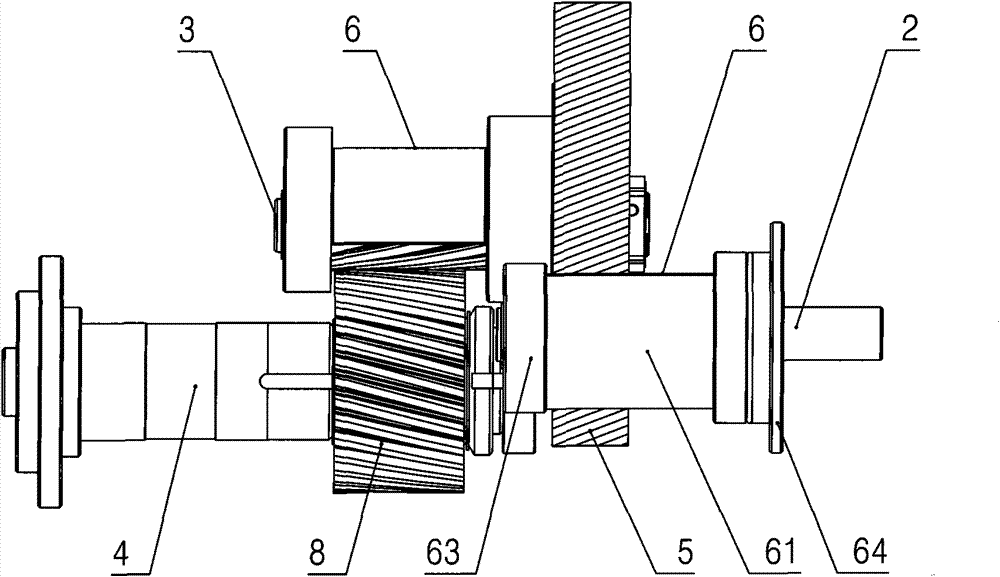

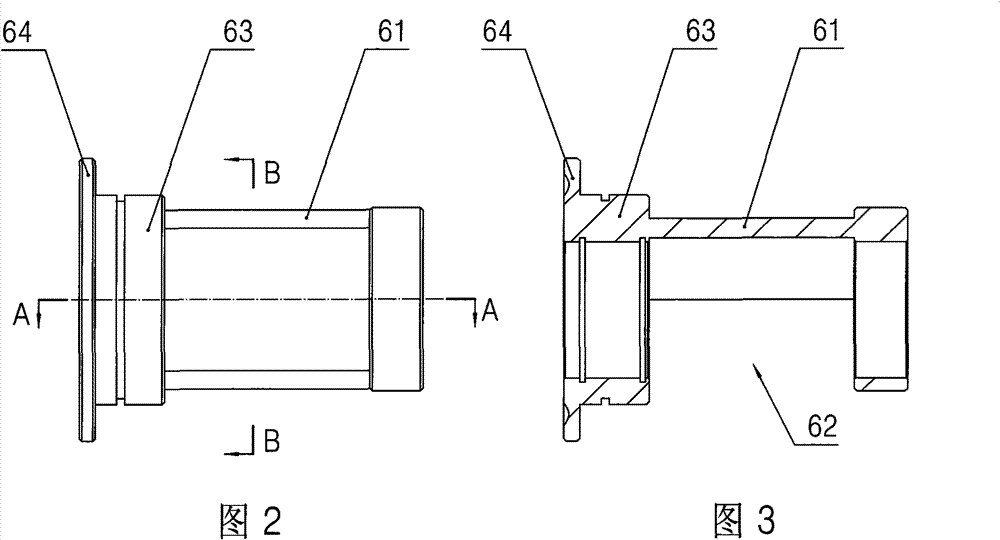

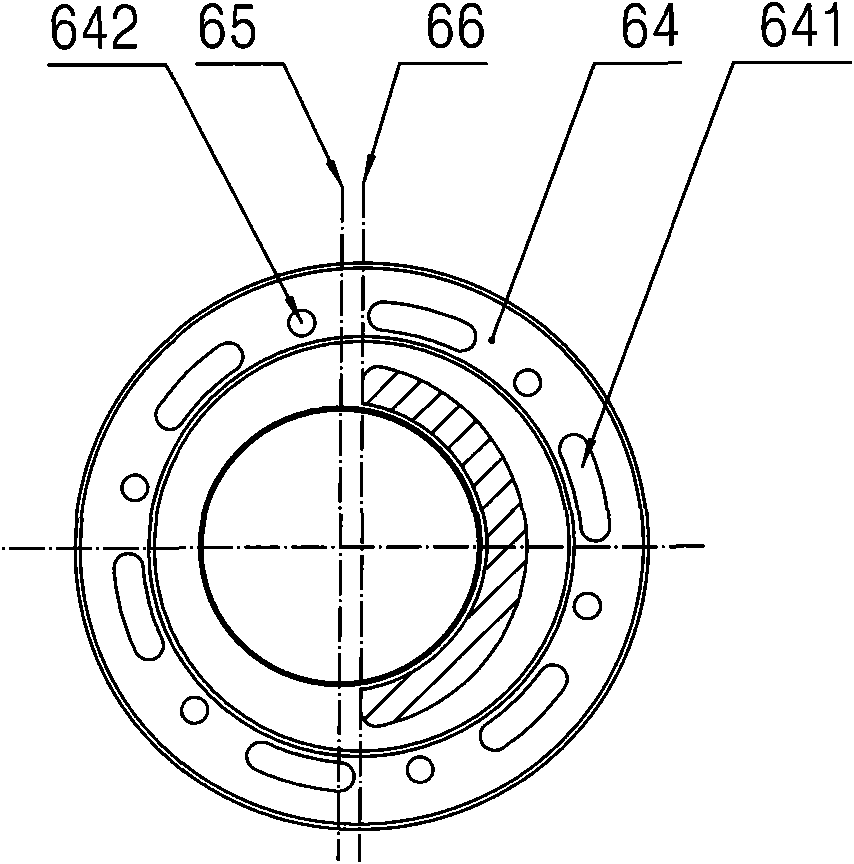

[0015] like figure 1 , Image 6 As shown, the gear transmission device of the present invention includes: a pair of eccentric sleeves 6 and a gear box, the gear box is provided with an input gear shaft 2, an output shaft 4, an intermediate gear shaft 3, and the input gear shaft 2 is provided with a main body Gear, the intermediate gear shaft 3 is provided with a transmission gear 5 in addition to the body gear, and the output shaft 4 is provided with an output gear 8. In order to more clearly reflect the input gear shaft 2, the intermediate gear shaft 3 and the output shaft 4 The transmission structure between the three, the gearbox is omitted in the figure; such as figure 2 , image 3 , Figure 4 and Figure 5 As shown, the eccentric sleeve 6 includes: an eccentric sleeve body 61—the eccentric axis 65 is eccentric with respect to the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com