Printing image defect detection method

A defect detection and image printing technology, which is applied in image analysis, image data processing, measuring devices, etc., can solve the problems of poor template self-adaptation and missed detection, and achieve high-speed detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

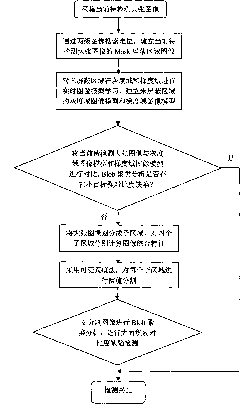

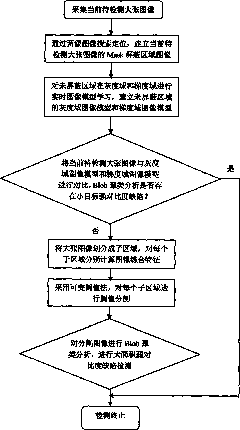

[0020] In a packaging paper printing production line, it is necessary to detect whether there are defects in the printed image. Using the printing image defect detection method of the present invention, such as figure 1 As shown, the specific steps are as follows:

[0021] First, collect the current large image to be detected, perform two-level image search and positioning on the current large image to be detected, select the watermark anti-counterfeiting pattern as the search and positioning template image, and then superimpose the template image on the current large image to be detected, And achieve search and positioning by panning, and search for the template on the large image Figure 1 Consistent specific image blocks, mask out other areas outside the specific image blocks, and create a Mask image.

[0022] The second step is to ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com