Counting and combining device

A conveying body and fast technology, which is applied in counting objects, counting mechanisms/items, counting of items shipped through conveying devices, etc. It can solve problems such as low confluence capacity, reduced capacity, and inability to change the density of materials to be confluent , to achieve the effect of improving utilization rate and confluence ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

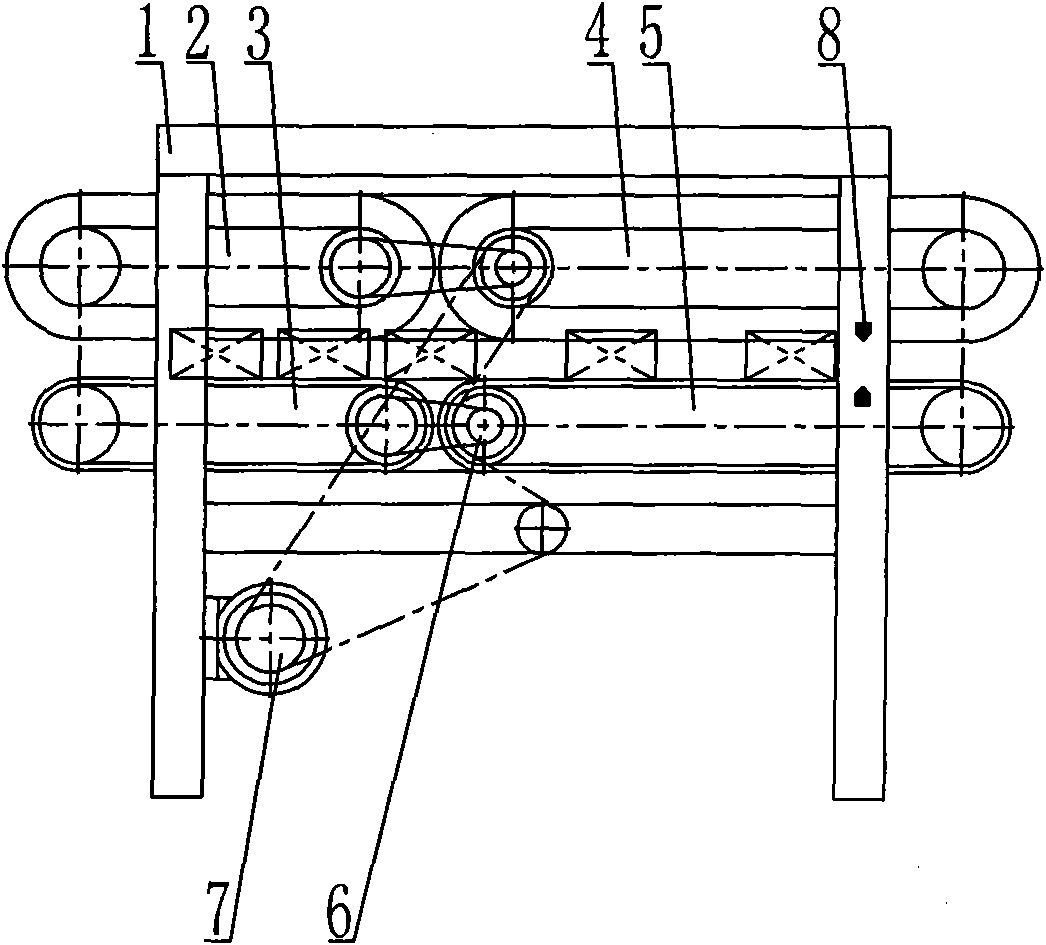

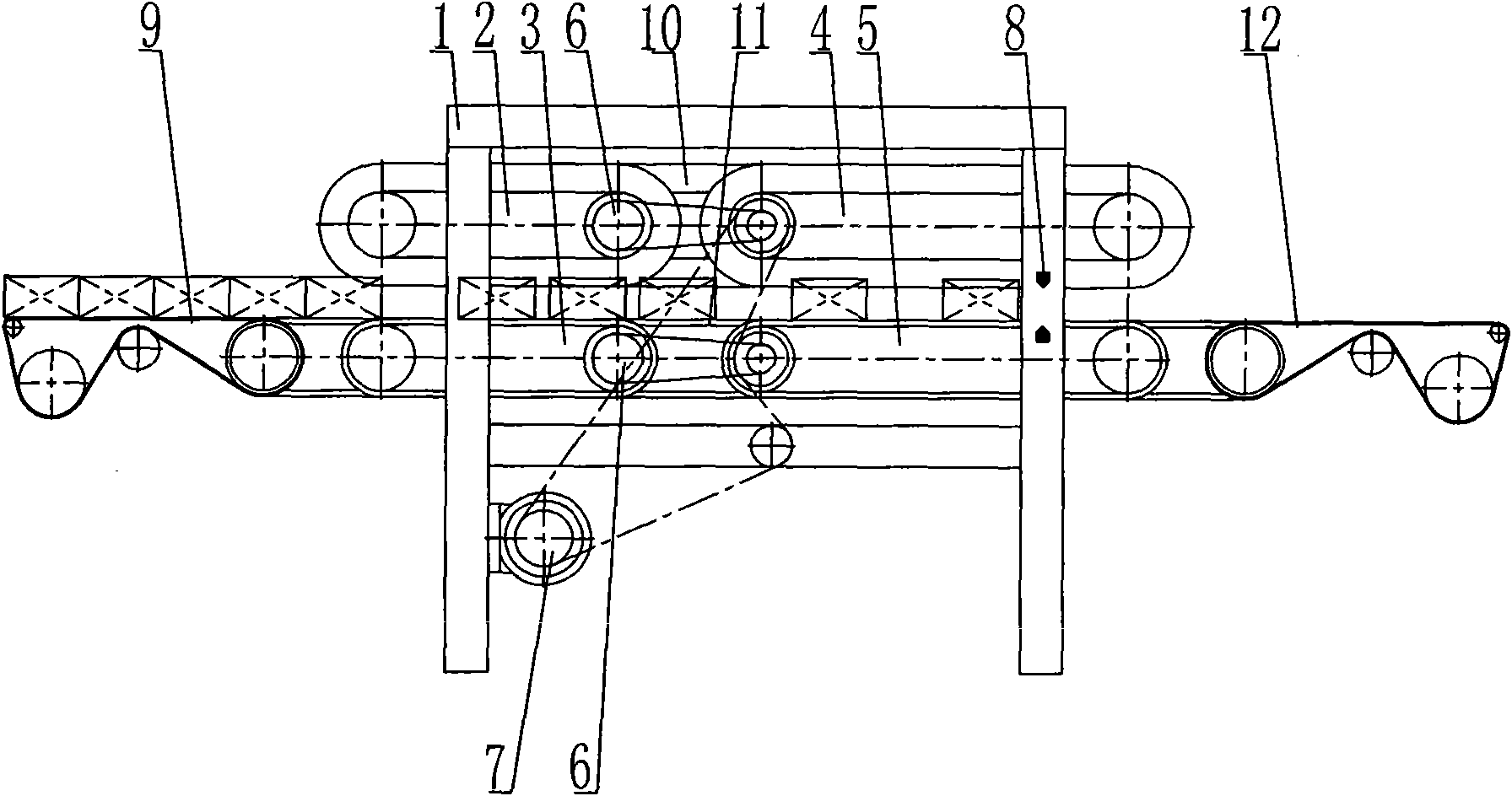

[0013] Such as figure 1 , figure 2 As shown, the counting and merging device described in this embodiment is a counting and merging device for completing cigarette rods. Body 5, speed difference mechanism 6, transmission mechanism 7, detection element 8, front transition conveying body 9, transition upper conveying body 10, transition lower conveying body 11 and rear transition conveying body 12 and other parts constitute.

[0014] The front transition conveying body 9 is a small conveyor, fixedly installed on the frame body 1, composed of driving rollers, passive rollers and steering rollers, etc., driven by independent power, to shape the rods conveyed by the upstream equipment; the slow upper part The conveying body 2, the slow lower conveying body 3, the fast upper conveying body 4, and the fast lower conveying body 5 are respectively composed of driving rollers, passive rollers and conveyor belts. Bearings are installed at both ends of the driving and passive rollers an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com