Precision strip heating element

A technology of heating elements and heating components, which is applied in the manufacture of furnace heating elements, electrical components, semiconductor/solid-state devices, etc., and can solve the problems of high labor of wire-type elements, operating temperature limit of wire-type elements, heating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

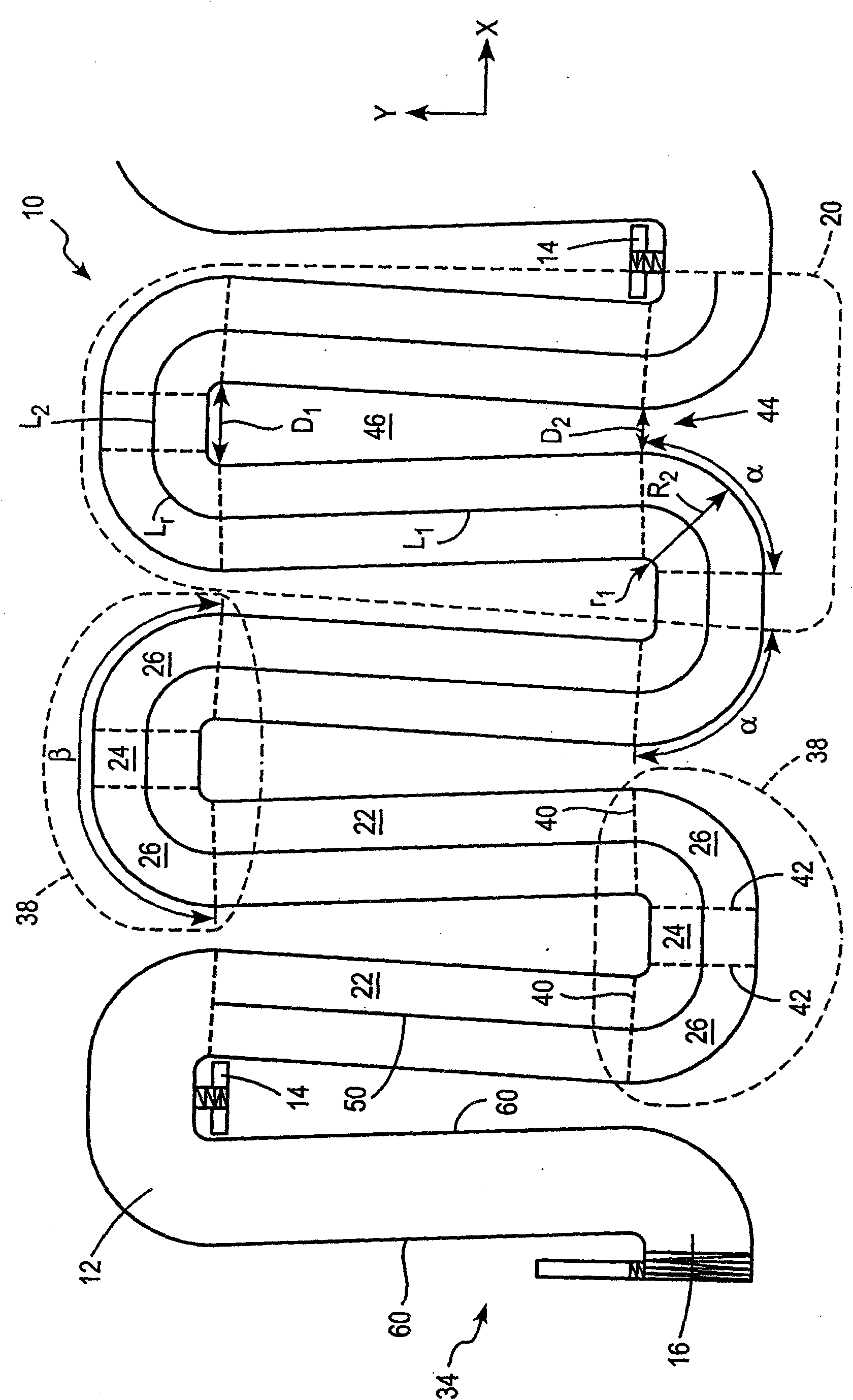

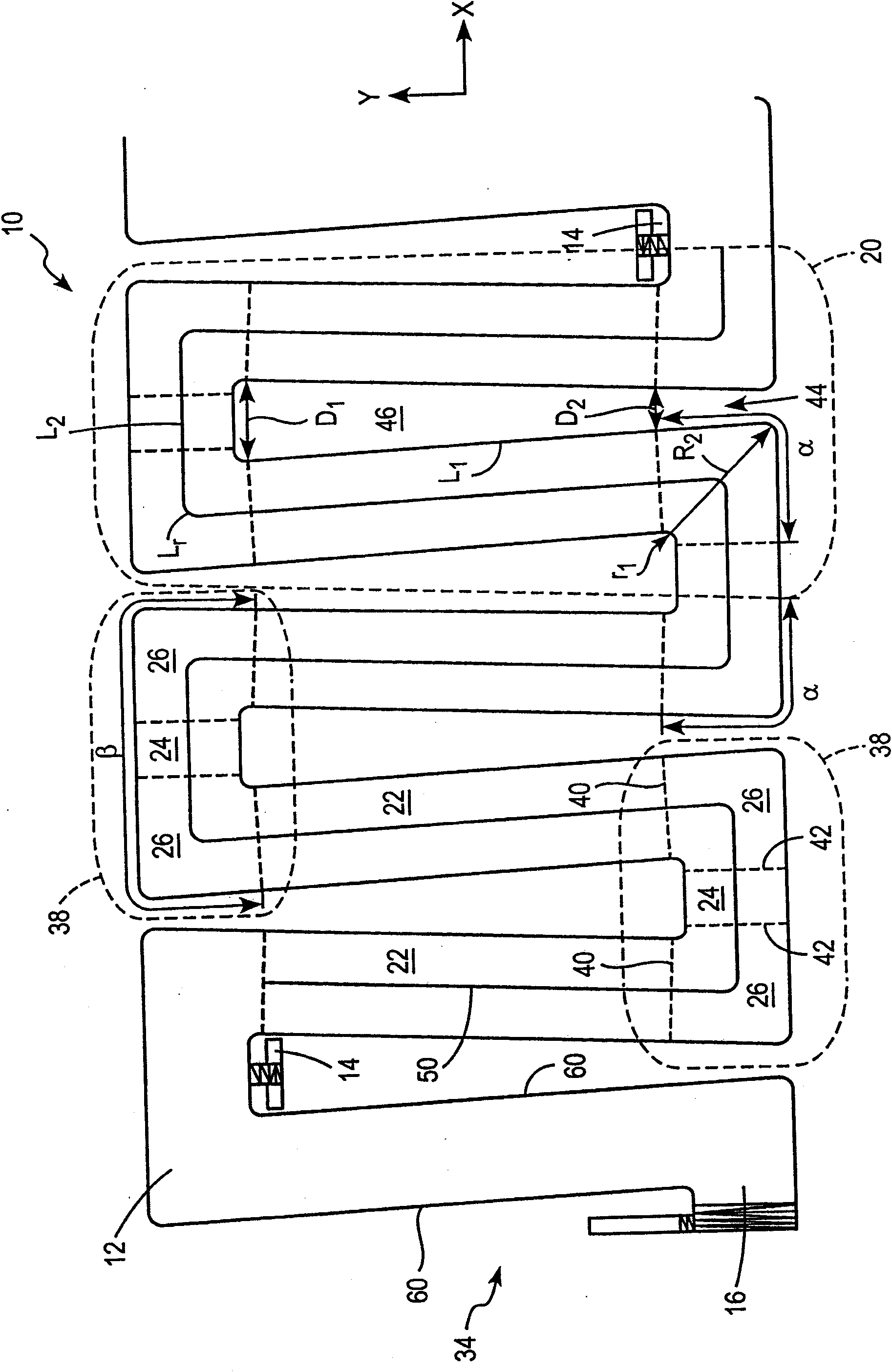

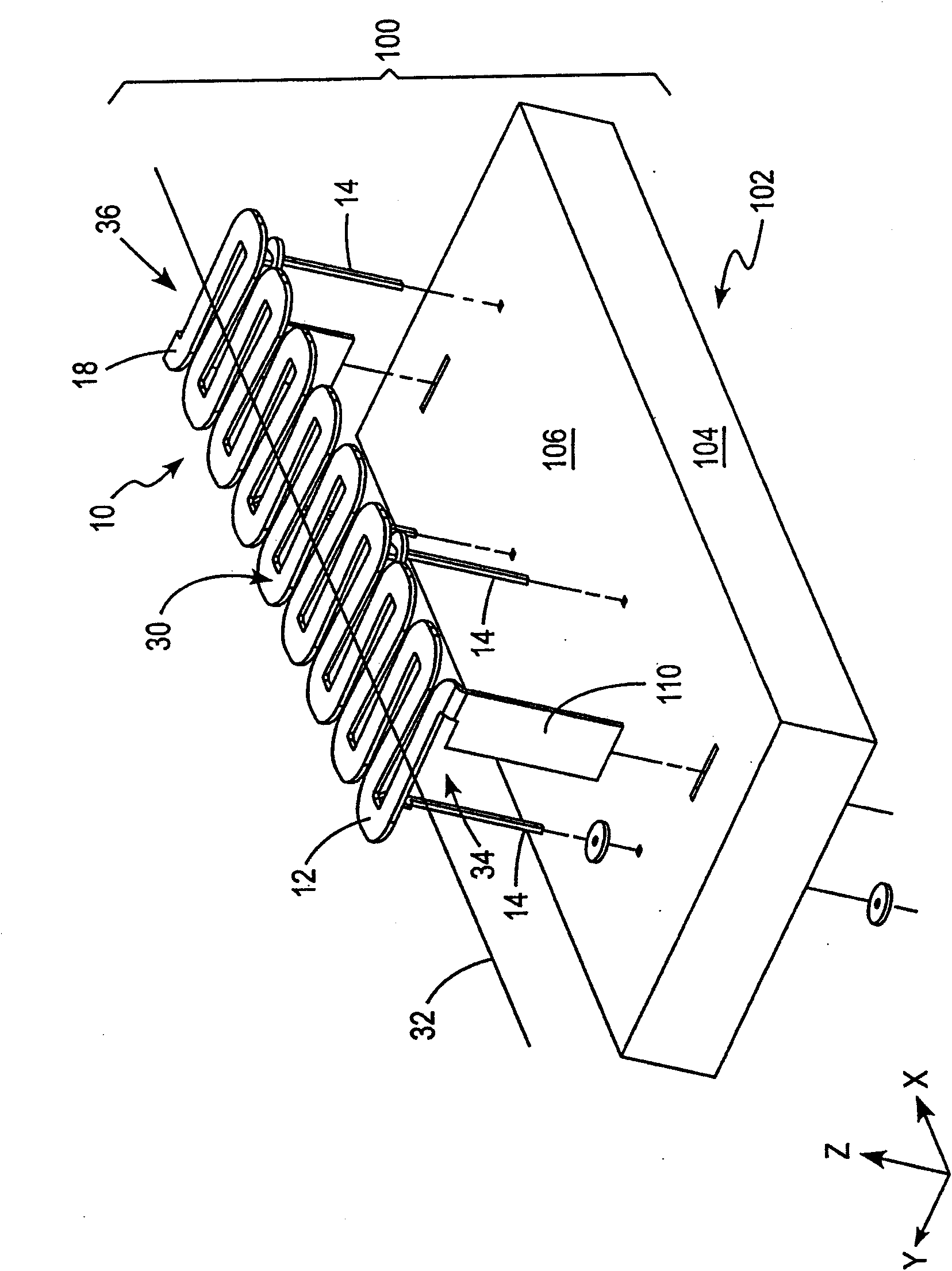

[0024] The exemplary embodiment of the heating element 10 includes a continuous planar strip 12 and a plurality of mounting members 14. The path of the continuous strip 12 from the first end 16 to the second end 18 is circuitous and includes a plurality of repeated loops 20. Each repeating cycle 20 includes a plurality of non-parallel first straight sections 22, a plurality of second straight sections 24, and a plurality of curved sections 26. The angle sum of a single loop of the circuitous path is greater than 360 degrees.

[0025] The heating element 10 has a radiating surface 30 that extends substantially in a first plane and is substantially contained in the first plane. In this first plane, for example within ±15 degrees perpendicular to the axis 32, a plurality of first straight segments 22 are oriented substantially transversely with respect to the axis 32, which extends from the first end of the heating element 10 34 is oriented to the second end 36 of the heating elem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com