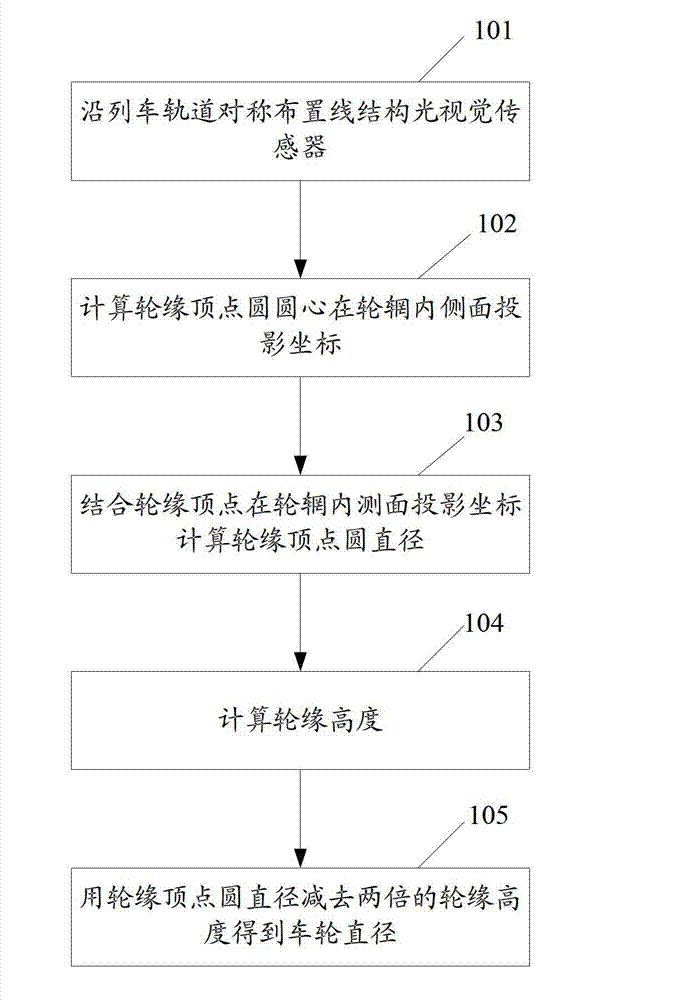

Dynamic measurement method and system for train wheel diameter

A wheel and profile technology, applied in the field of measurement, can solve the problems of high requirements for on-site installation, great influence on measurement accuracy, low dynamics, etc., to avoid difficult positioning of measuring points, reduce machining costs, and on-site installation requirements. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

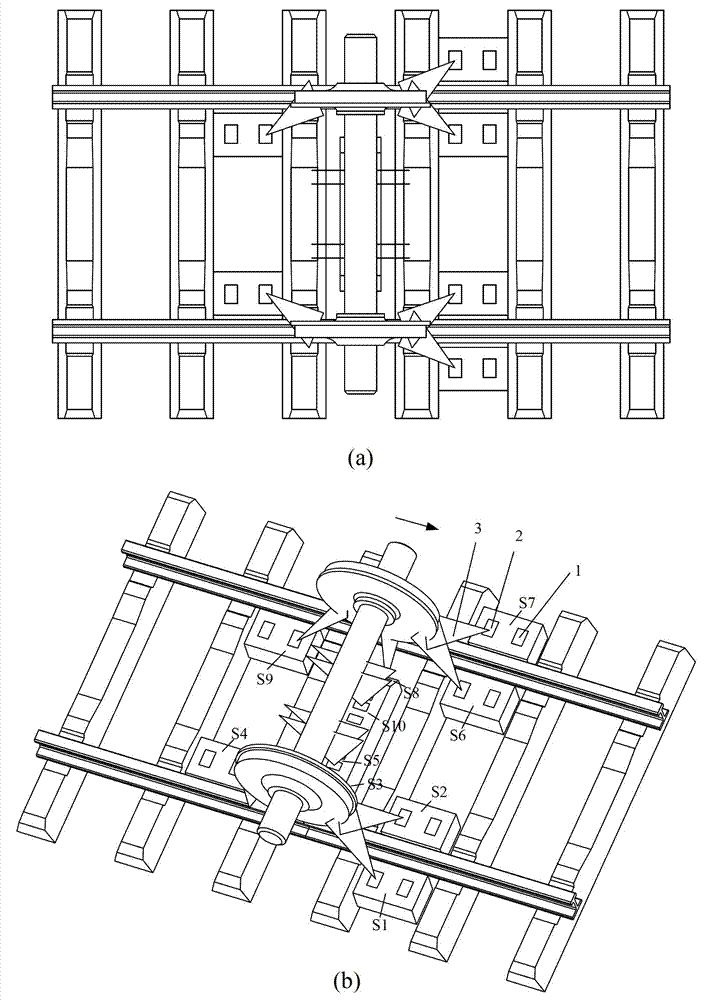

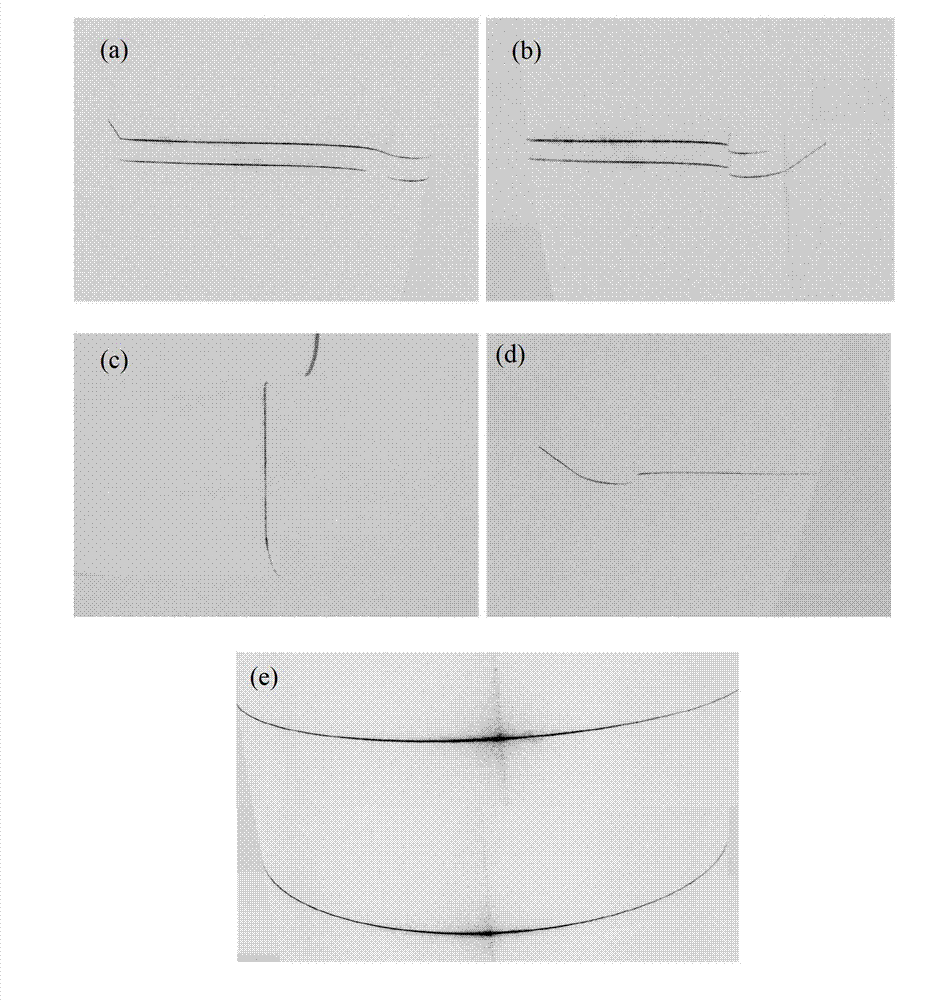

[0059] The invention provides a dynamic measurement system for the diameter of a train wheel, which utilizes the visual measurement principle of line structured light, adopts a line structured light visual sensor to obtain the cross-sectional profile light strip images of the wheel and the axle respectively, and each line structured light visual sensor consists of more than one Composed of a laser projector and a CCD camera; specifically, 2N line structured light vision sensors are symmetrically arranged on both sides of the rail along the track, and every N line structured light vision sensors complete the measurement of the wheel diameter on one side; The measurement of the wheel is observed by M line-structured light vision sensors to form a wheel observation module to obtain light strip images of more than three cross-sectional profiles of the wheel. Among them, 2i line-structured light vision sensors are arranged symmetrically along the rail to form i pairs of wheel tread o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com