Pneumatic tire

A technology for pneumatic tires and tires, which is applied in the direction of pneumatic tires, tire parts, tire treads/tread patterns, etc. It can solve the problems of increasing the volume and the inability to fully increase the total groove length, etc., and achieve the purpose of improving the sound absorption effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

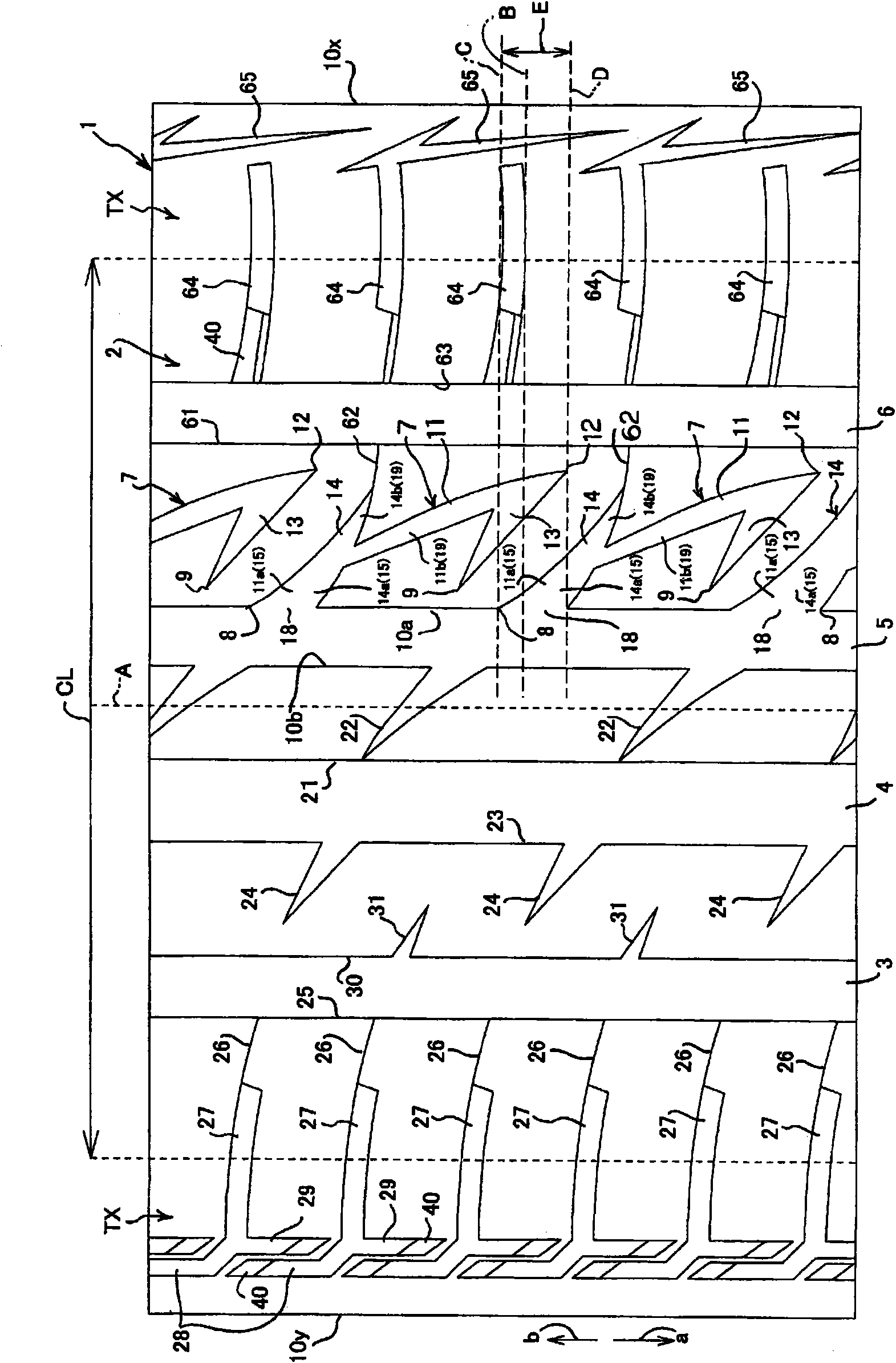

[0029] figure 1 with Figure 5 Indicates Embodiment 1, figure 1 Indicates the groove structure (tread pattern) of the tire contact surface of the pneumatic tire, Figure 5 Indicates the relationship between the turn-back ditch of the horizontal ditch and the other side ditch.

[0030] Such as figure 1 As shown, the tire contact surface (tread portion) 2 of the pneumatic tire 1 (hereinafter simply referred to as the tire 1) has a plurality of circumferential grooves 3, 4, 5, 6 and a plurality of lateral grooves 7, 7 . . . . Each of the circumferential grooves 3 , 4 , 5 , 6 is formed continuously in one circle along the circumferential direction of the tire contact surface 2 . The plurality of lateral grooves 7 are formed extending from one circumferential groove 5 formed at a position closest to the equatorial plane A of the tire 1 . The circumferential groove 5 is formed at a position deviated from the equatorial plane A of the tire 1 toward the one side edge 10x side of ...

Embodiment approach 2

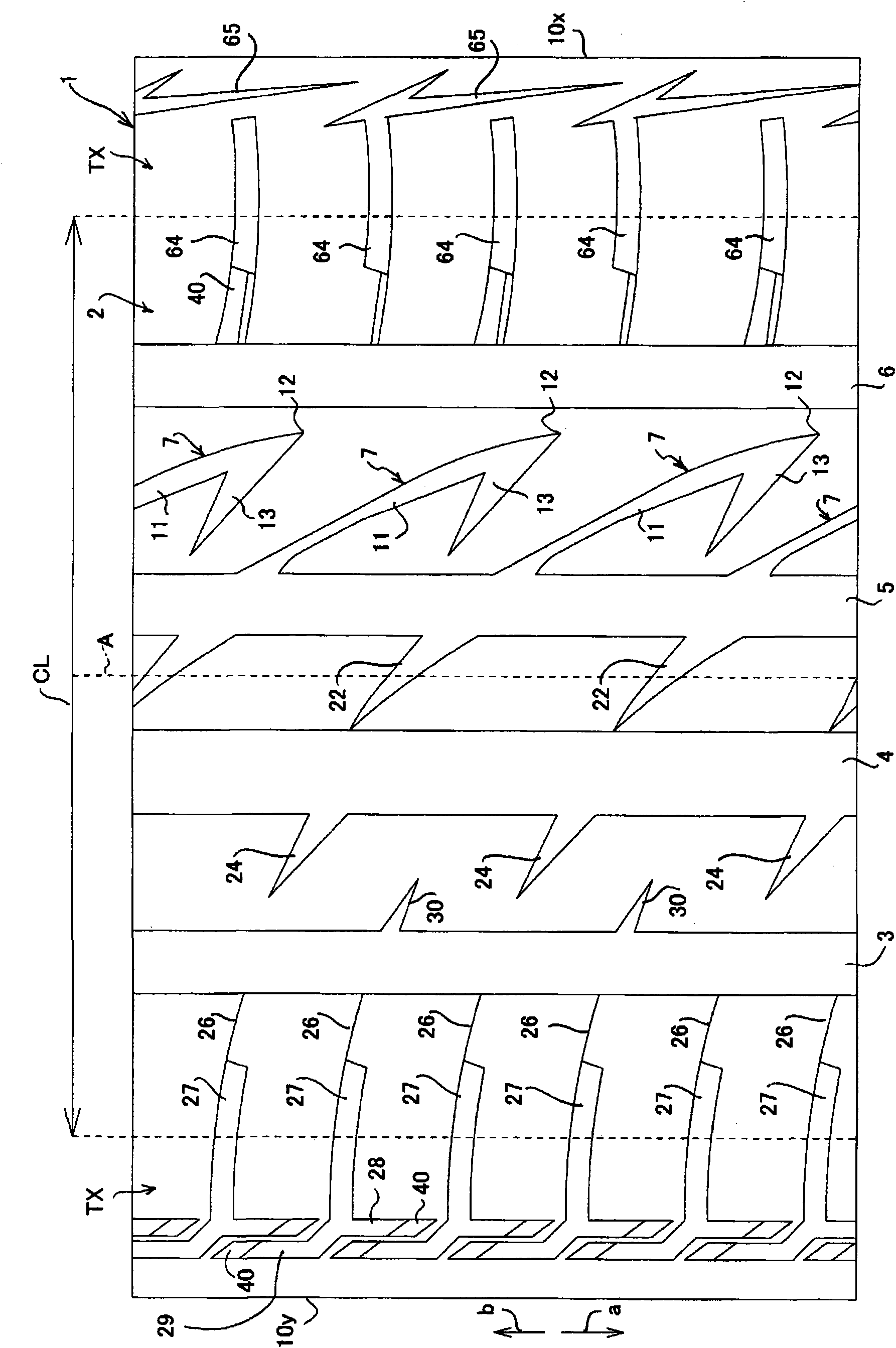

[0048] Such as figure 2 As shown, the lateral groove 7 is formed by the one-way groove 11 and the return groove 13, and other structures may be the pneumatic tire 1 having the tire contact patch 2 formed in the same manner as in the first embodiment.

[0049] According to Embodiment 2, since the lateral groove 7 is formed of the one-way groove 11 and the folded groove 13, the total length of the grooves responsible for the sound absorbing effect can be ensured, and thus the sound absorbing effect can be enhanced by the lateral groove 7. In the case of Embodiment 2, by setting the extension length of the one-way groove 11 to 9 cm and the extension length of the return groove 13 to 4 cm, the total length of the grooves bearing the sound-absorbing effect can be ensured to be relatively long. Compared with the case of the directional groove 11, the effect of absorbing lower frequency sound can be obtained.

Embodiment approach 3

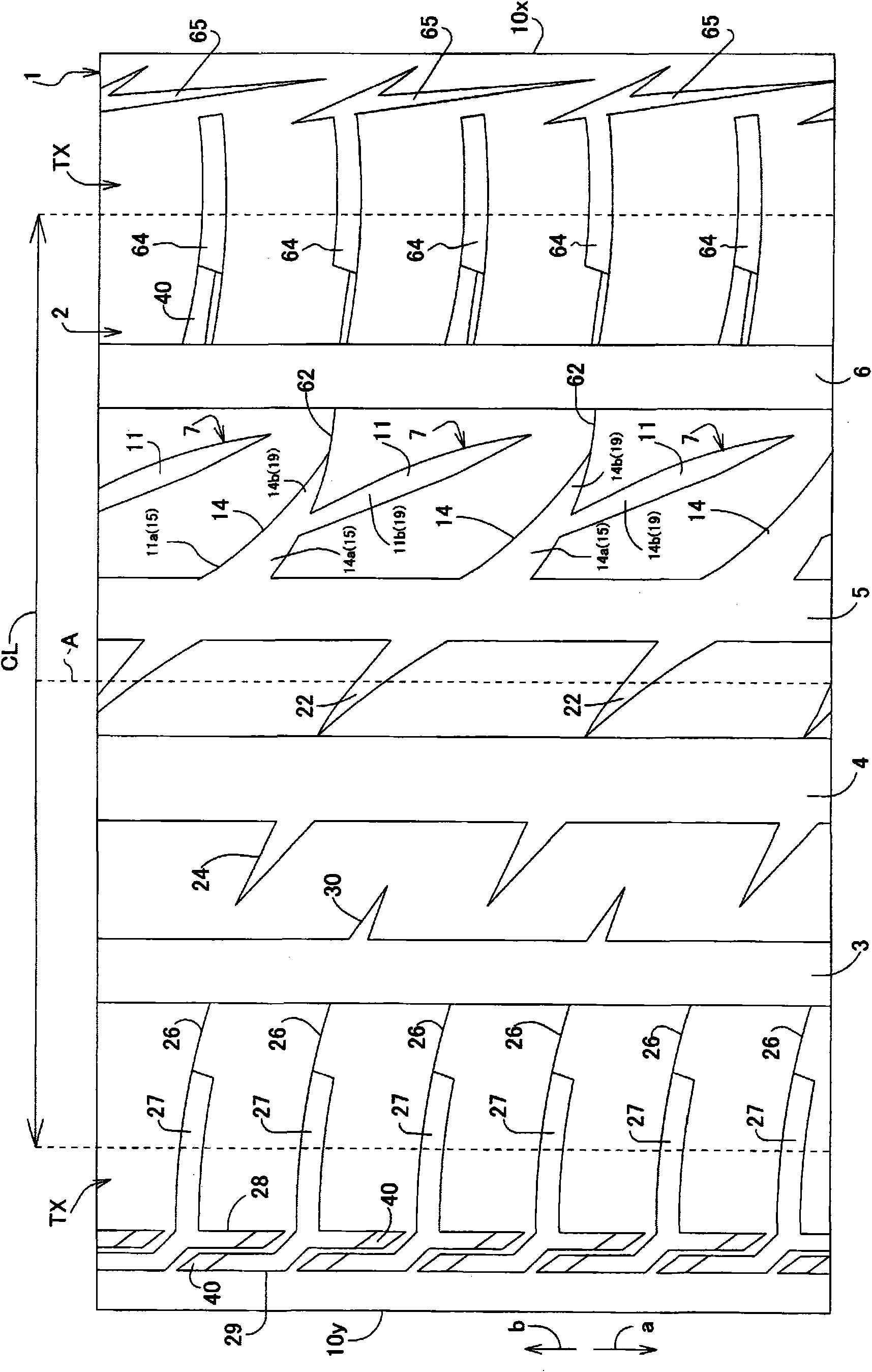

[0051] Such as image 3 As shown, the lateral groove 7 is formed of one directional groove 11 and the other directional groove 14 , and other structures may be the pneumatic tire 1 having the tire contact patch 2 formed in the same manner as in the first embodiment.

[0052] According to Embodiment 3, since the lateral groove 7 is formed by the one direction groove 11 and the other direction groove 14, the one direction groove 11 having a longer groove length bears the effect of absorbing the sound of a specific frequency, and the other direction groove 14 uses the other direction groove. The volume increases the total groove volume of the lateral grooves 7, and therefore, the sound absorbing effect by the lateral grooves 7 can be enhanced. In the case of Embodiment 3, by making the extending length of the one-directional groove 11 9 cm and the extending length of the other-directional groove 14 4 cm, the total groove volume is increased compared to the case where only the one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com