continuous ink supply system

A technology of ink supply and ink, applied in the field of ink supply system, can solve problems such as suspension of printing work, pollution, occupying a large space, etc., and achieve the effect of reducing operation difficulty, avoiding environmental pollution, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The implementation of the present invention will be described in more detail below with reference to the drawings and component symbols, so that those skilled in the art can implement it after studying this specification.

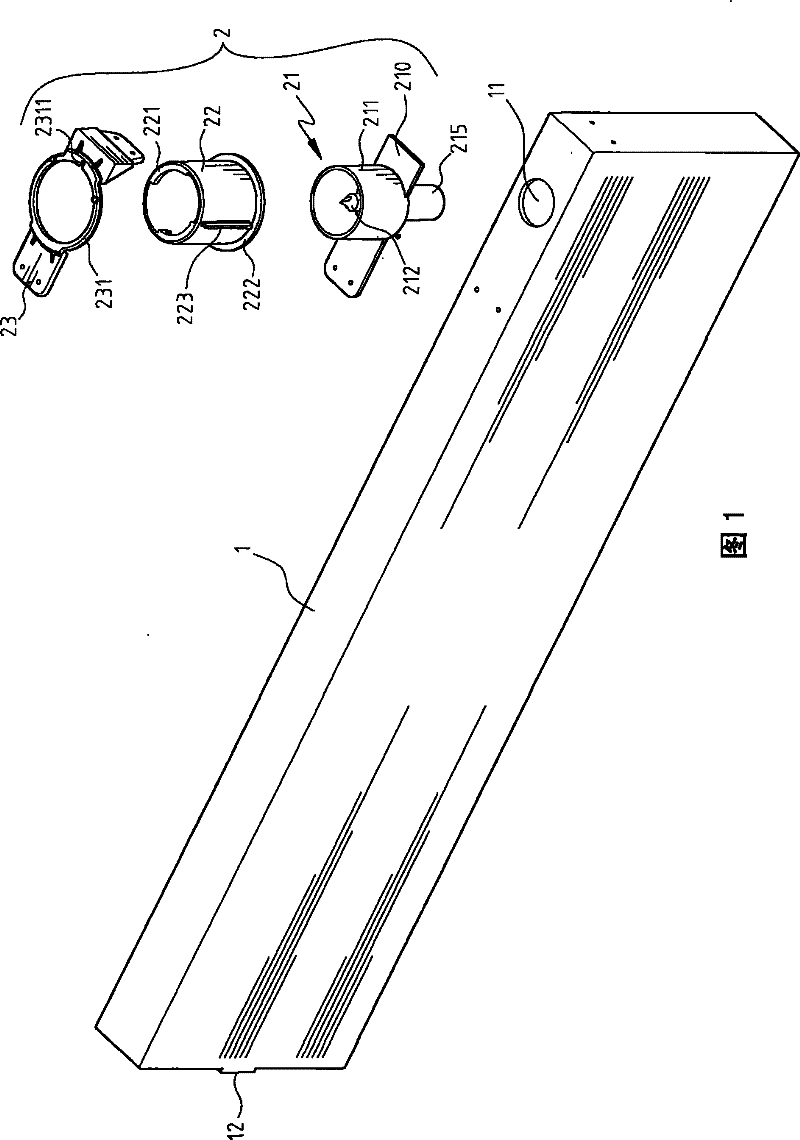

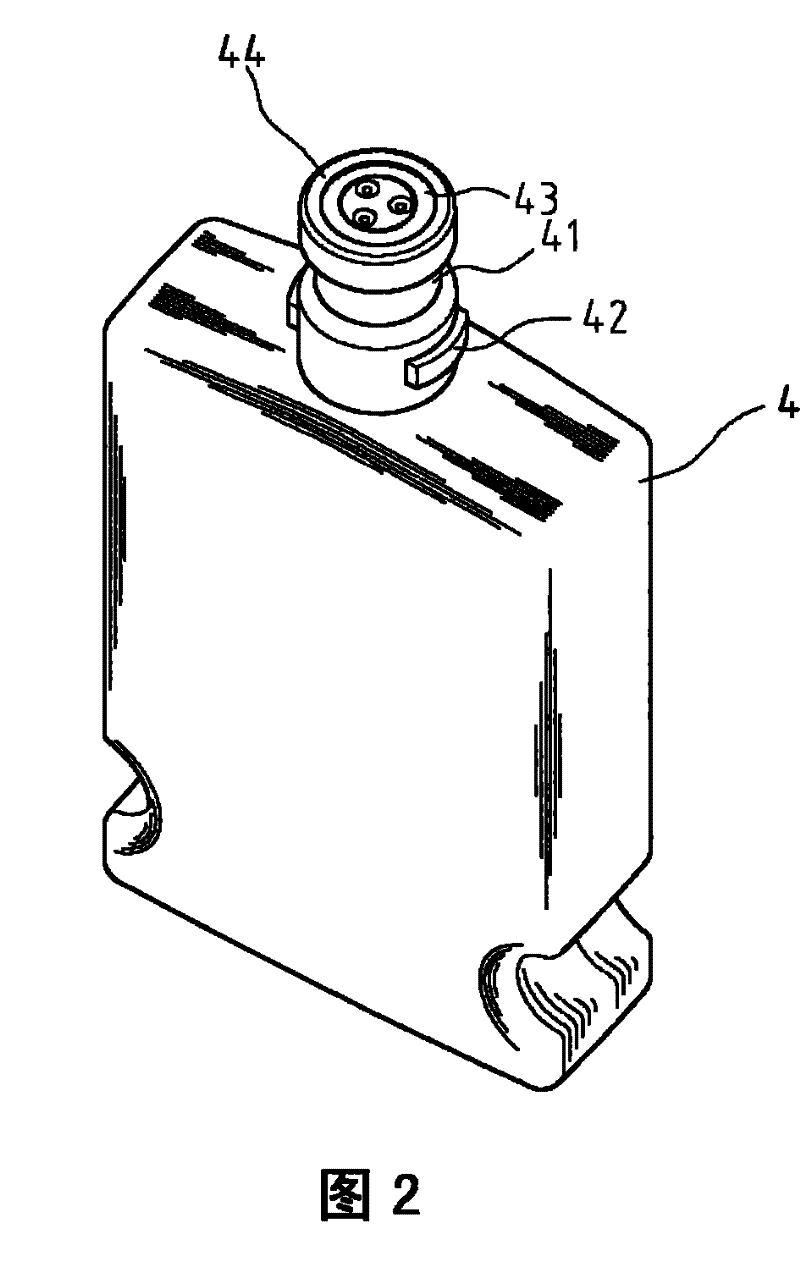

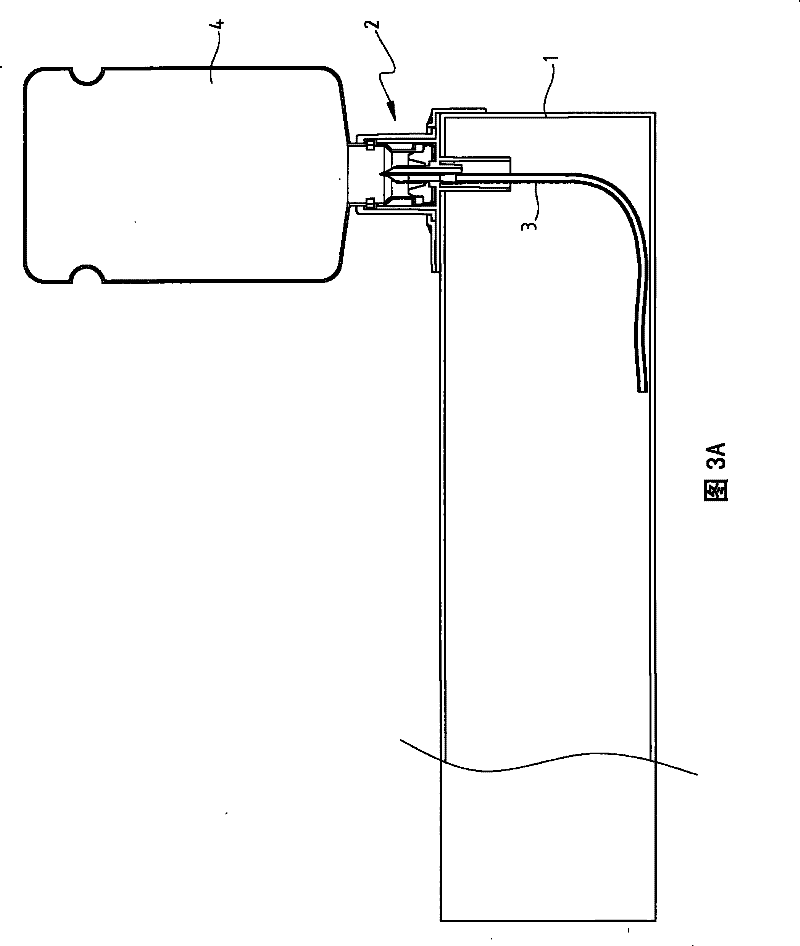

[0022] The continuous ink supply system provided by the present invention includes figure 1 Shown ink cartridge body 1, connecting device 2, and figure 2 The ink replenishment box 4 shown; the connection device 2 is provided on the ink cartridge body 1 as an interface device that the ink replenishment case 4 and the ink cartridge body 1 are connected to each other; the ink cartridge body 1, the connection device 2 and the ink replenishment box 4 The shape system after mutual combination is as follows Figure 3A shown.

[0023] see again figure 1 and Figure 3B , the preferred embodiment of the present invention for the ink cartridge body 1 is that any suitable material can be used to form a container with a cavity, and at least one input port 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com