Protection cover for protecting laser marking machine and laser marking machine cabinet

A laser marking machine and laser marking technology, applied in the field of laser marking, can solve the problems that the laser marking machine cannot be directly applied to the slaughtering site, and cannot implement batch counterfeiting, etc., and achieves the effect of good protection and improved service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the above-mentioned objects, features and advantages of the present invention more obvious and understandable, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

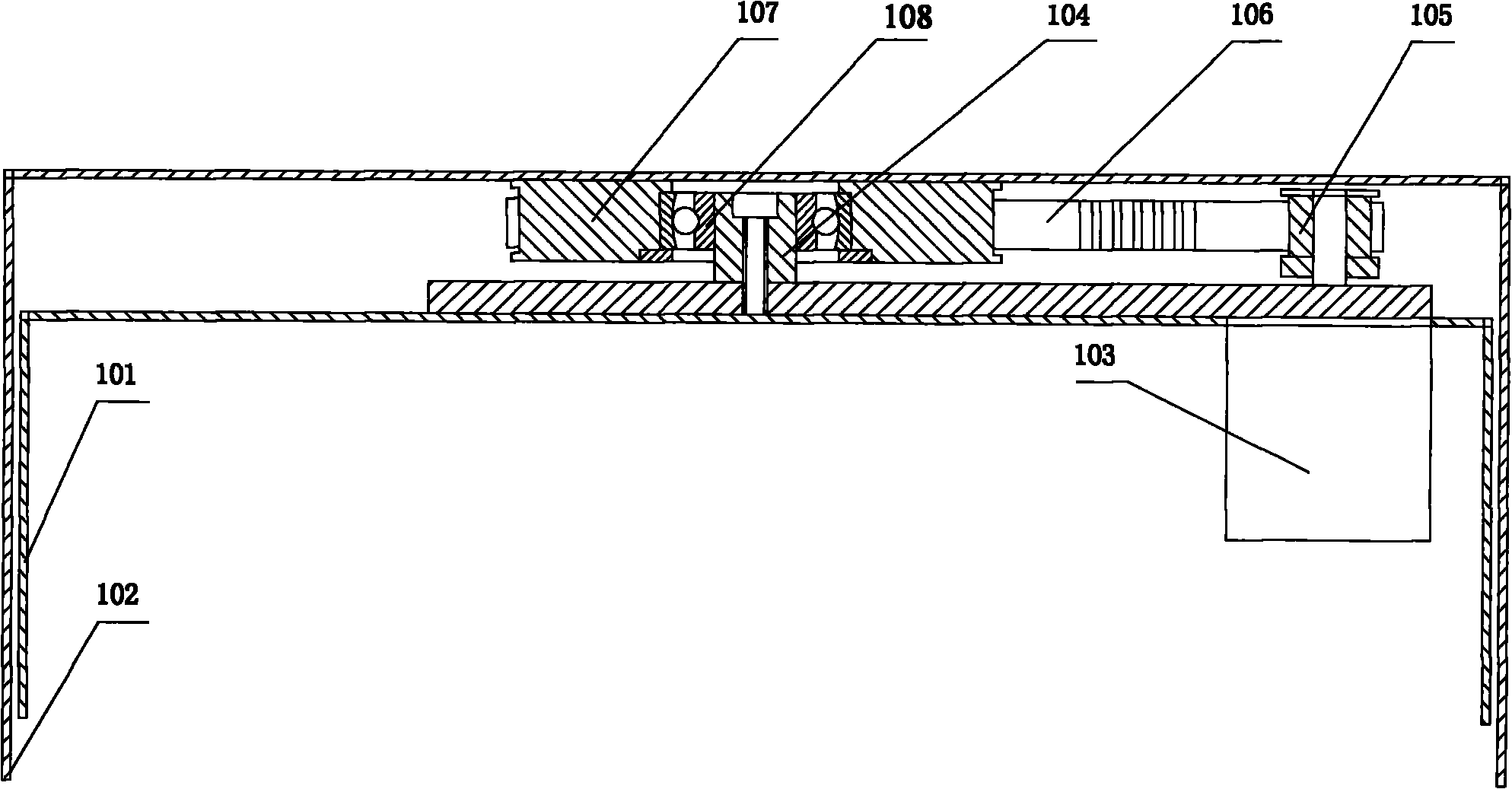

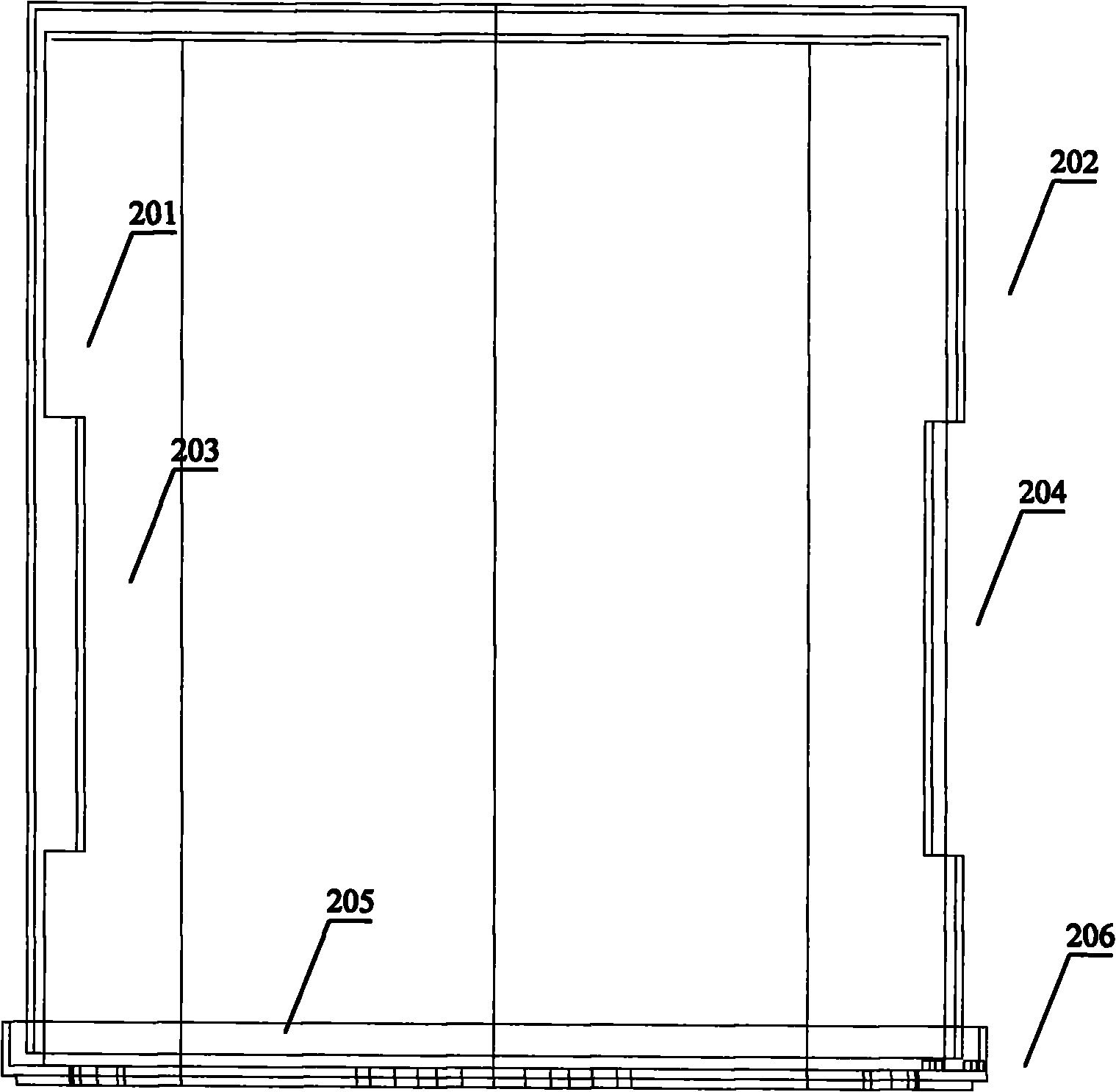

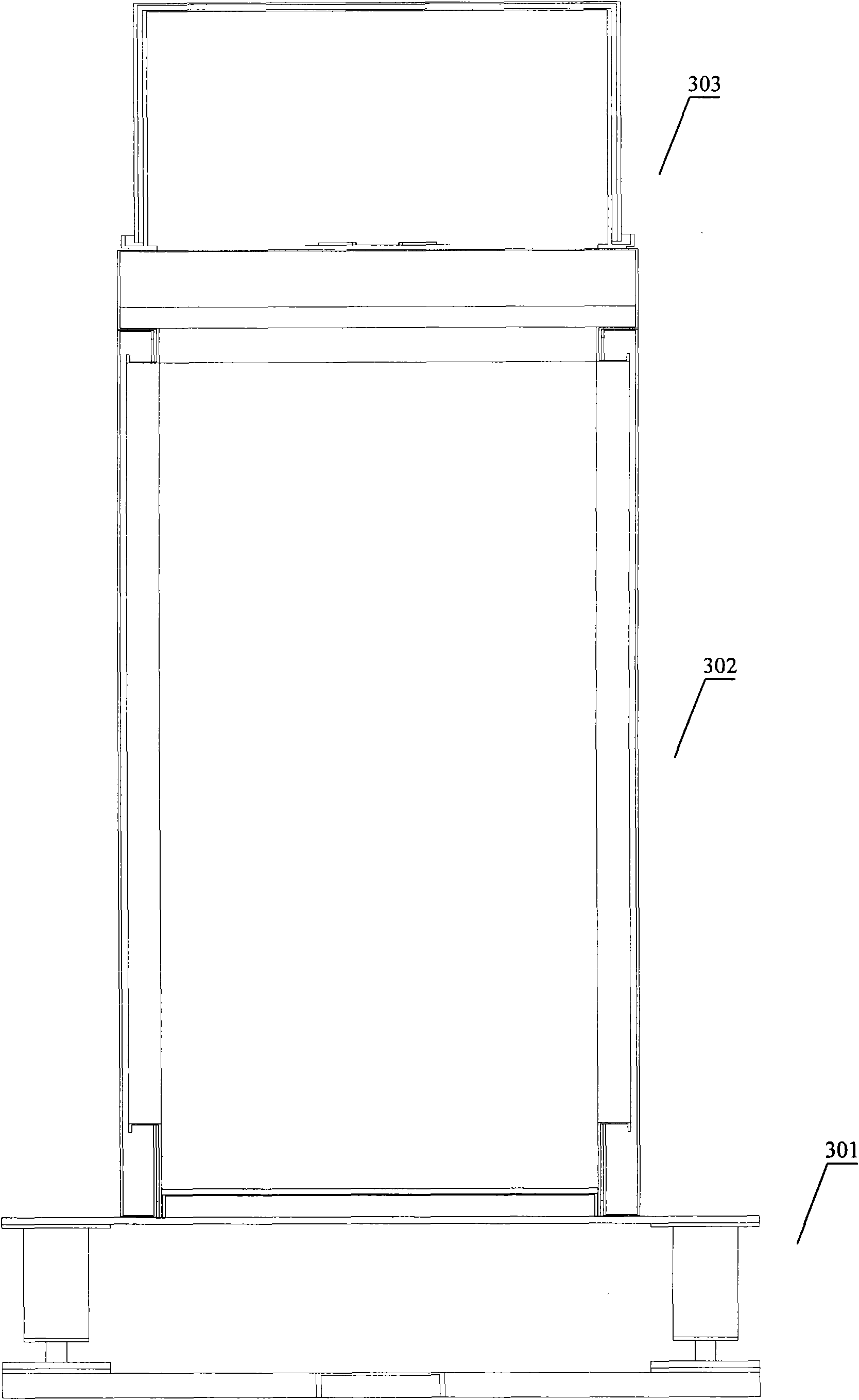

[0034] One of the core concepts of the embodiments of the present invention is to protect the laser beam exit port with a protective cover to prevent the cleaning liquid from splashing and affecting the laser; at the same time, in order to ensure the normal laser emission, a laser exit hole is opened on the protective cover. However, due to the laser light exit hole, liquid will still splash into the laser light exit hole on the protective cover during cleaning, which may affect the laser. Therefore, in the present invention, a double-layer turret inner sleeve and Turret jacket. When the laser exit holes of the two overlap, the laser beam can be emitted to the surface of the poultry to be marked; when the laser e...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap