Scale advanced treatment method for livestock and poultry farming waste water

A technology for advanced treatment of livestock and poultry breeding wastewater, applied in the field of advanced treatment of large-scale livestock and poultry breeding wastewater, can solve problems such as increased treatment costs, and achieve the effects of simple operation, good economic and environmental benefits, and simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

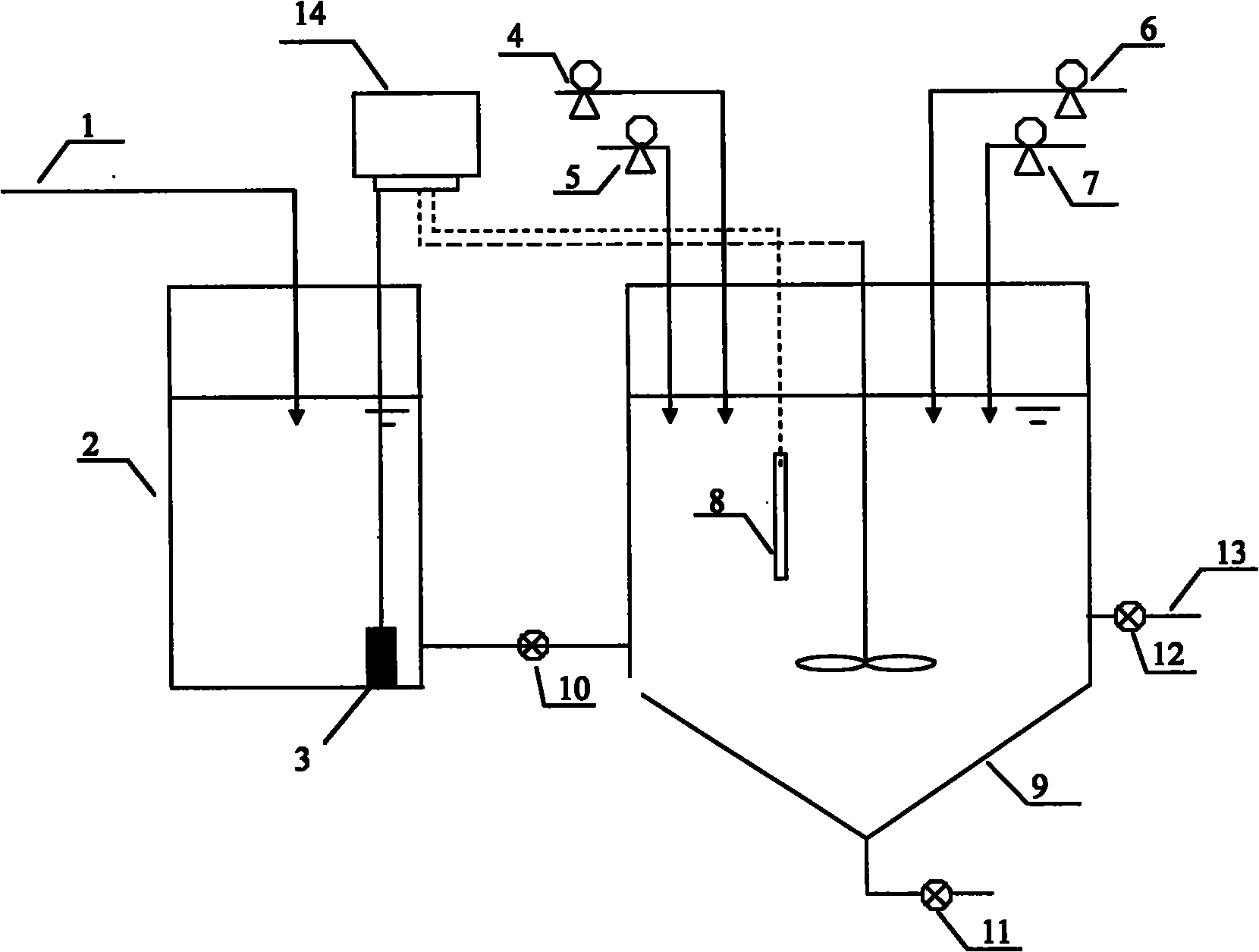

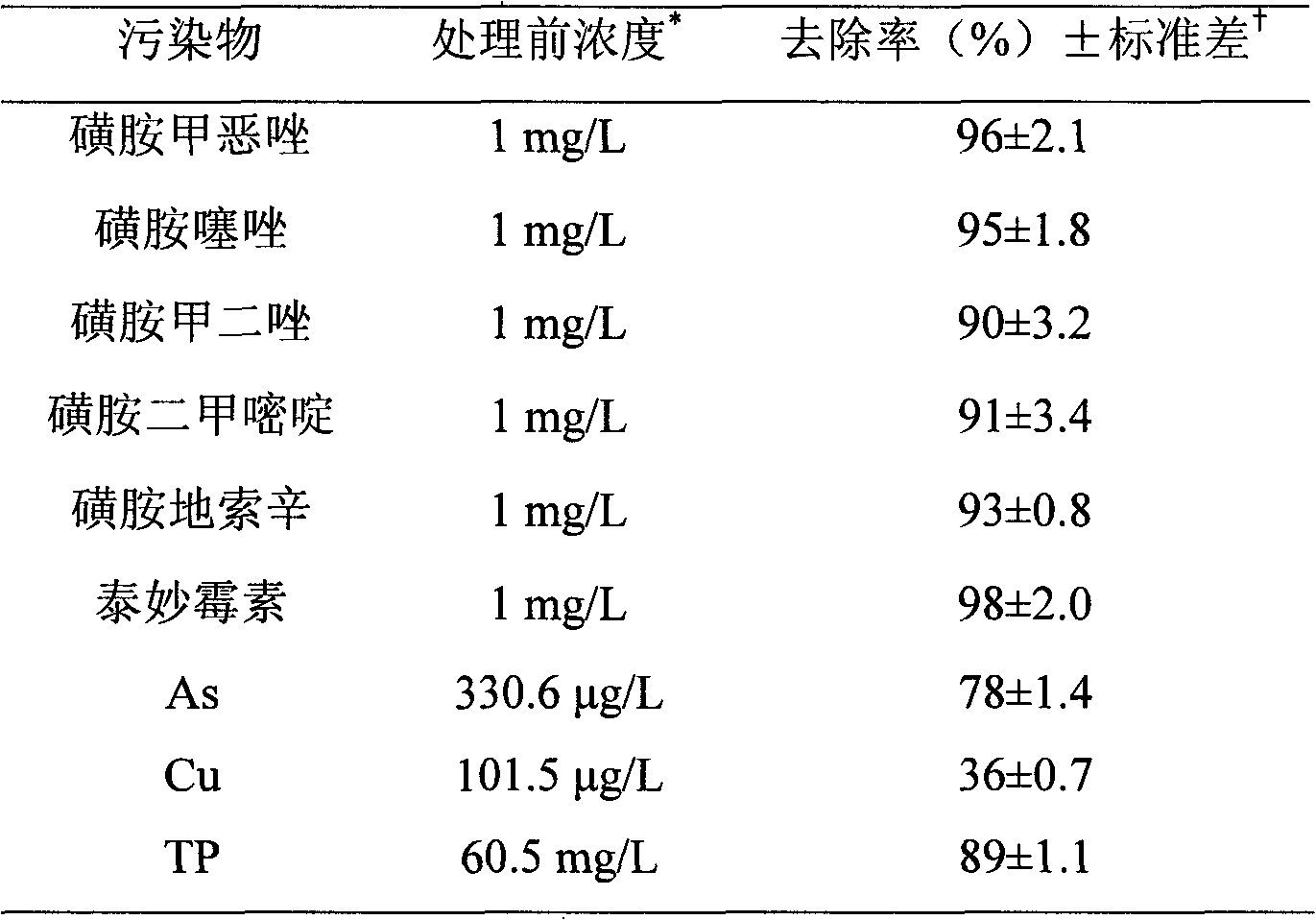

[0027] After the wastewater from an intensive pig farm is treated by the Sequential Batch Activated Sludge Process (SBR), the commonly used antibiotics for livestock in the effluent include sulfonamides (sulfamethoxazole, sulfathiazole, sulfamethizole, sulfamethazine , sulfidesoxine) and tiamulin concentrations were added to 1mg / L. Adopt the method of the present invention, in figure 1 The effluent is treated in the Fenton integrated treatment device. The biological treatment effluent continuously enters the sump, and the water inlet valve is kept open to allow the waste water to enter the main reactor. When the liquid level detector indicates that the set liquid level is reached, the water inlet valve is closed to start the Fenton reaction cycle. Under the condition of sufficient stirring, add acid to the main reactor through the acid pump to reduce the pH value of the system. After the pH reaches 5.0, turn on the H 2 o 2 Dosing pump and FeSO 4 Dosing pump, the opening ti...

Embodiment 2

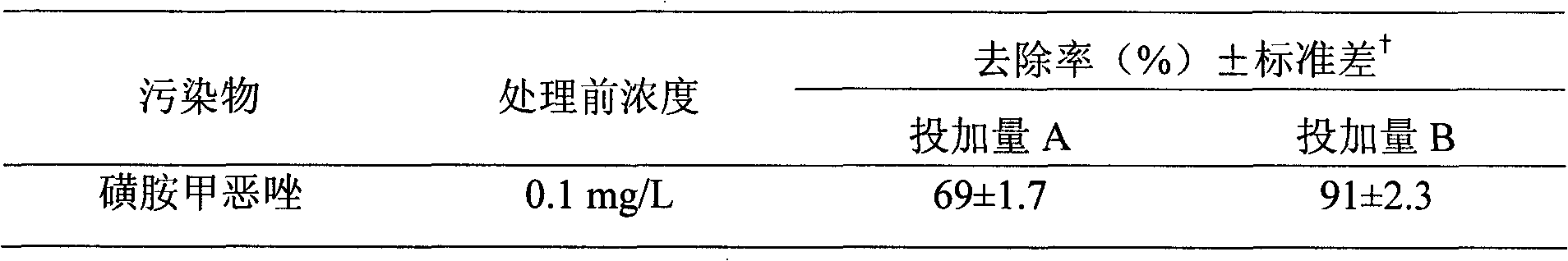

[0033] Due to factors such as seasonal changes and management methods, the water quality of the biological treatment effluent will fluctuate. According to the monitoring results of the type and concentration of antibiotics in the effluent, the dosage of Fenton reagent can be adjusted accordingly. In the biological treatment effluent of an intensive pig farm, sulfonamides (sulfamethoxazole, sulfathiazole, sulfamethizole, sulfamethazine, sulfidexoxine), tetracyclines (tetracycline, oxytetracycline, aureomycin Su) and tiamulin concentrations were added to 0.1mg / L. Adopt the method of the present invention, in figure 1 The effluent is treated in the Fenton integrated treatment device. Two kinds of Fenton reagent dosages are adopted, and the dosage A is [H 2 o 2 ]=1.37mmol / L, [Fe 2+ ]=0.91mmol / L, dosage B is 2 times of A, see Table 2 for the treatment effect of antibiotics and phosphorus. At dosage B, all 9 kinds of antibiotics and phosphorus can be effectively removed. Since ...

Embodiment 3

[0038] In the advanced treatment of wastewater from certain intensive pig farms, through the method of the present invention, two kinds of Fenton reagent dosages are adopted, and the dosage A is [H 2 o 2 ]=1.37mmol / L, [Fe 2+ ]=0.91mmol / L, dosage B is 5 times of A, and the disinfection and sterilization effect of the system is shown in Table 3. Under the dosage A, the total number of bacteria in the wastewater can be from 10 6 The cfu / mL is reduced to 4500cfu / mL to ensure that the number of fecal coliform bacteria in the final effluent reaches the standard specified in GB18596-2001 (10000 / mL). Appropriately increasing the dosage of Fenton's reagent can further improve the disinfection effect.

[0039] Table 3 embodiment 3 processing effect ( Parallel samples n=3)

[0040]

[0041] Total number of bacteria (cfu / mL) *

[0042]

[0043] Biological treatment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com