Aqueous solution for clathrate hydrate formation, heat-storage agent, process for producing clathrate hydrate or slurry thereof, method for storing/radiating heat, and method for preparing aqueous solution for forming latent-heat-storage agent or major component thereof

A technology of clathrate hydrate and aqueous solution, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of time-consuming, separation, and inability to obtain supercooling inhibition effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0116] Best Mode for Carrying Out the Invention

[0117] Hereinafter, the present invention will be described in detail through embodiments. The following will explain one by one:

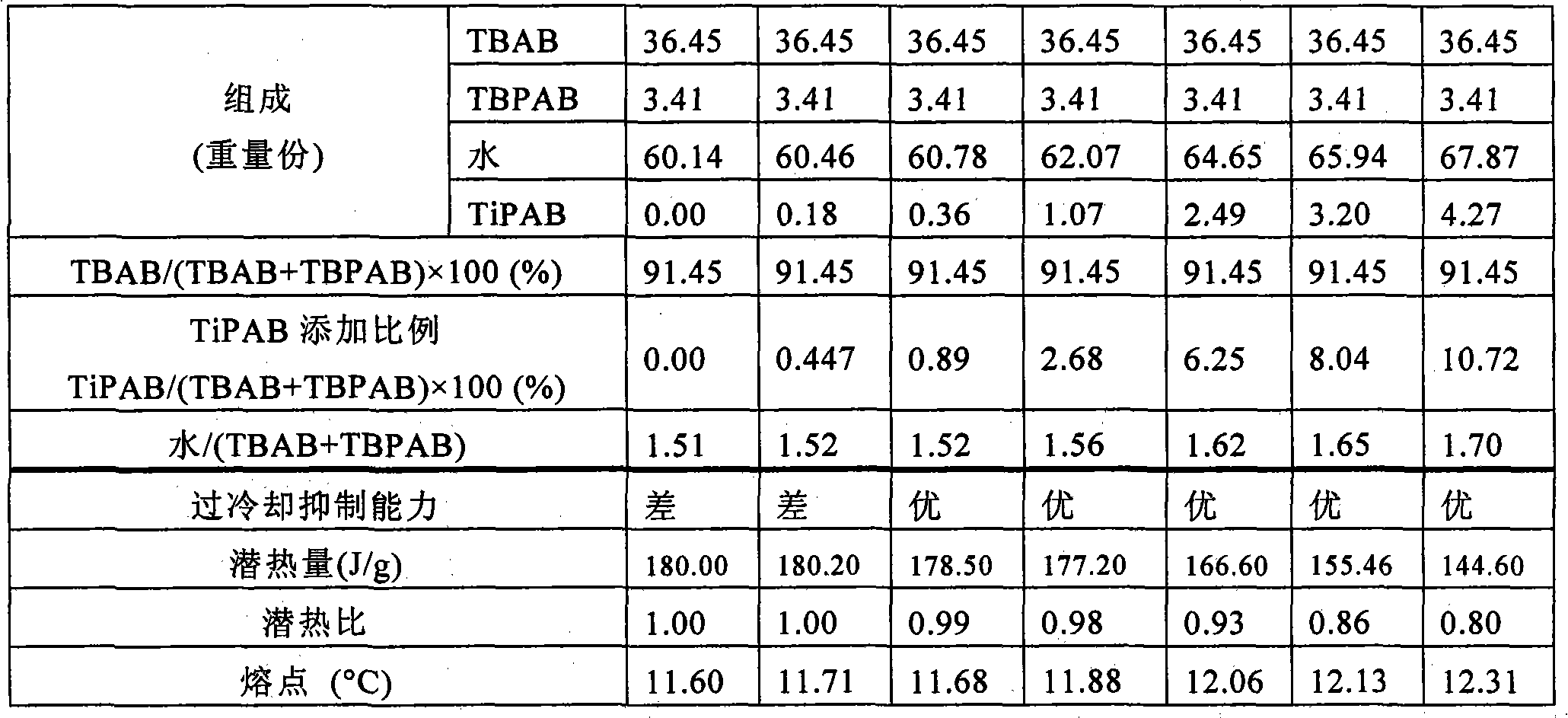

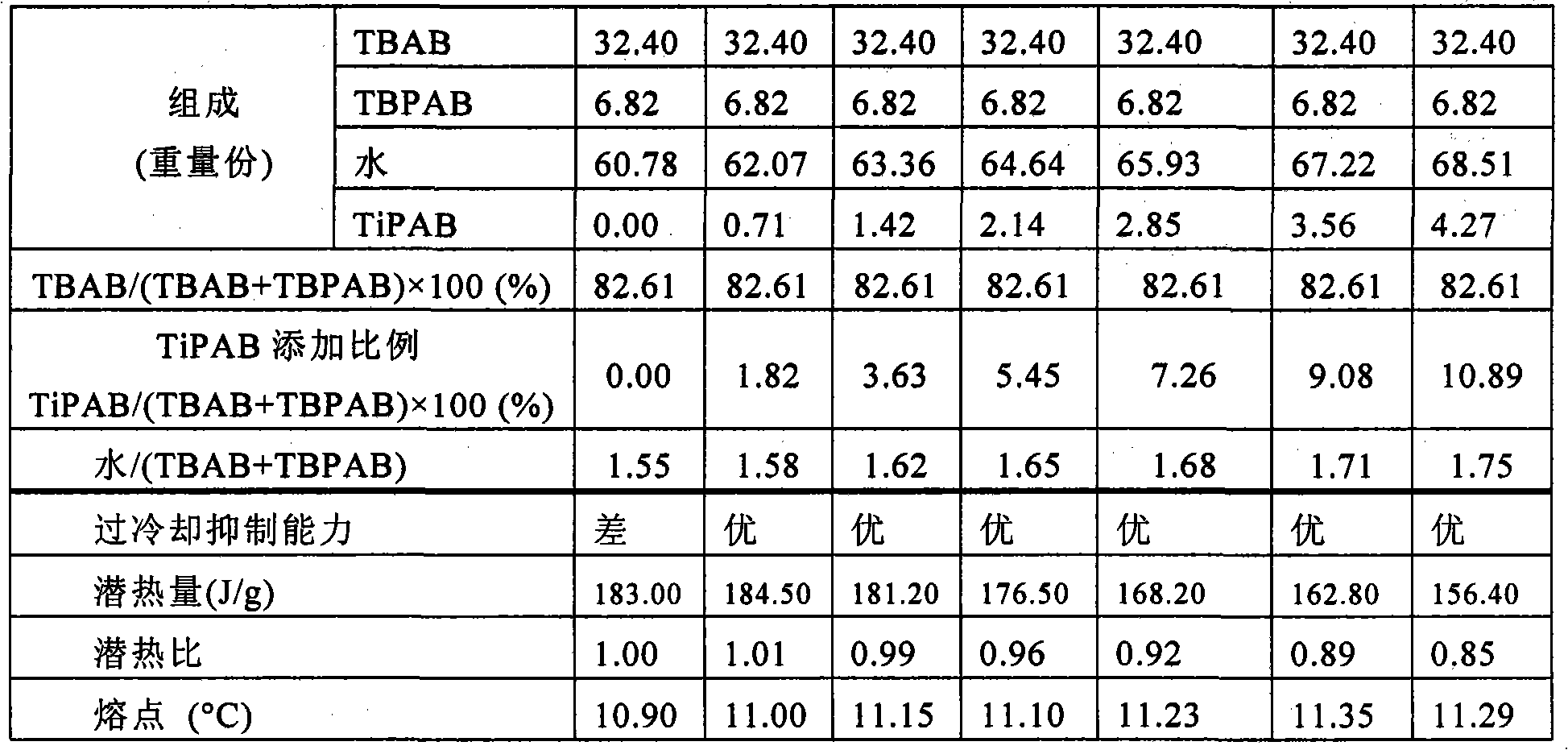

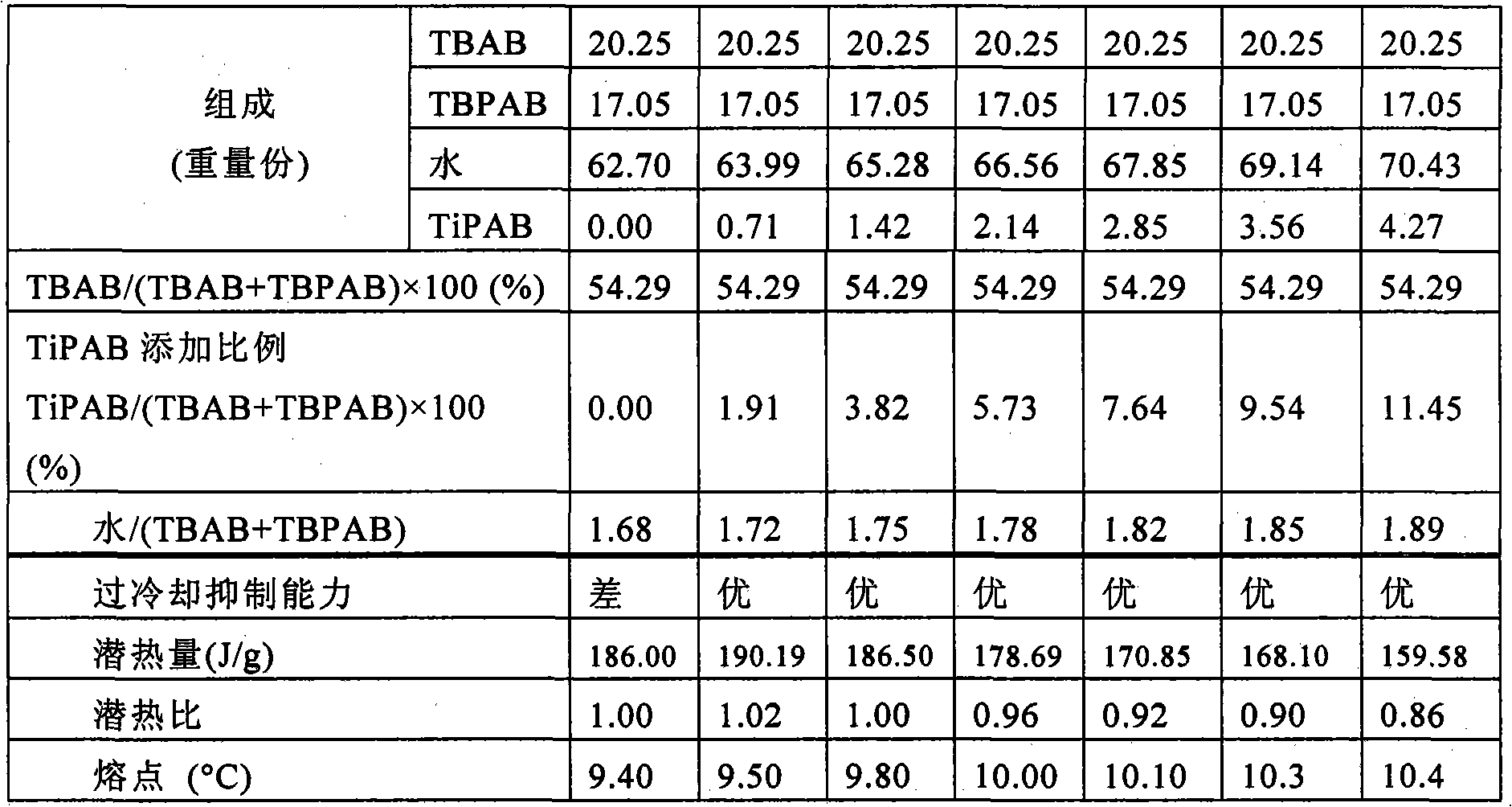

[0118] (A) heat storage agent containing tetra-n-butylammonium bromide, tetra-isopentylammonium bromide and water, (B) containing tri-n-butyl-n-pentylammonium bromide and tetra-isopentylammonium bromide and A heat storage agent of water, and (C) a heat storage agent comprising tetra-n-butylammonium bromide, tri-n-butyl-n-pentylammonium bromide, tetra-isopentylammonium bromide and water.

[0119] Hereinafter, for convenience, tetra-n-butylammonium bromide is sometimes abbreviated as "TBAB", tri-n-butyl-n-pentylammonium bromide is abbreviated as "TBPAB", and tetra-isopentylammonium bromide Abbreviated as "TiPAB".

[0120] (A) Heat storage agent containing tetra-n-butylammonium bromide, tetra-isopentylammonium bromide and water

[0121] 1. The new findings of the present invention will be describe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com