Pump, particularly for a hydraulic unit of an electronically controlled vehicle brake unit

A technology of electric motors and pump casings, applied to pumps of hydraulic devices, can solve the problems of increased bearing wear, flushing out, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

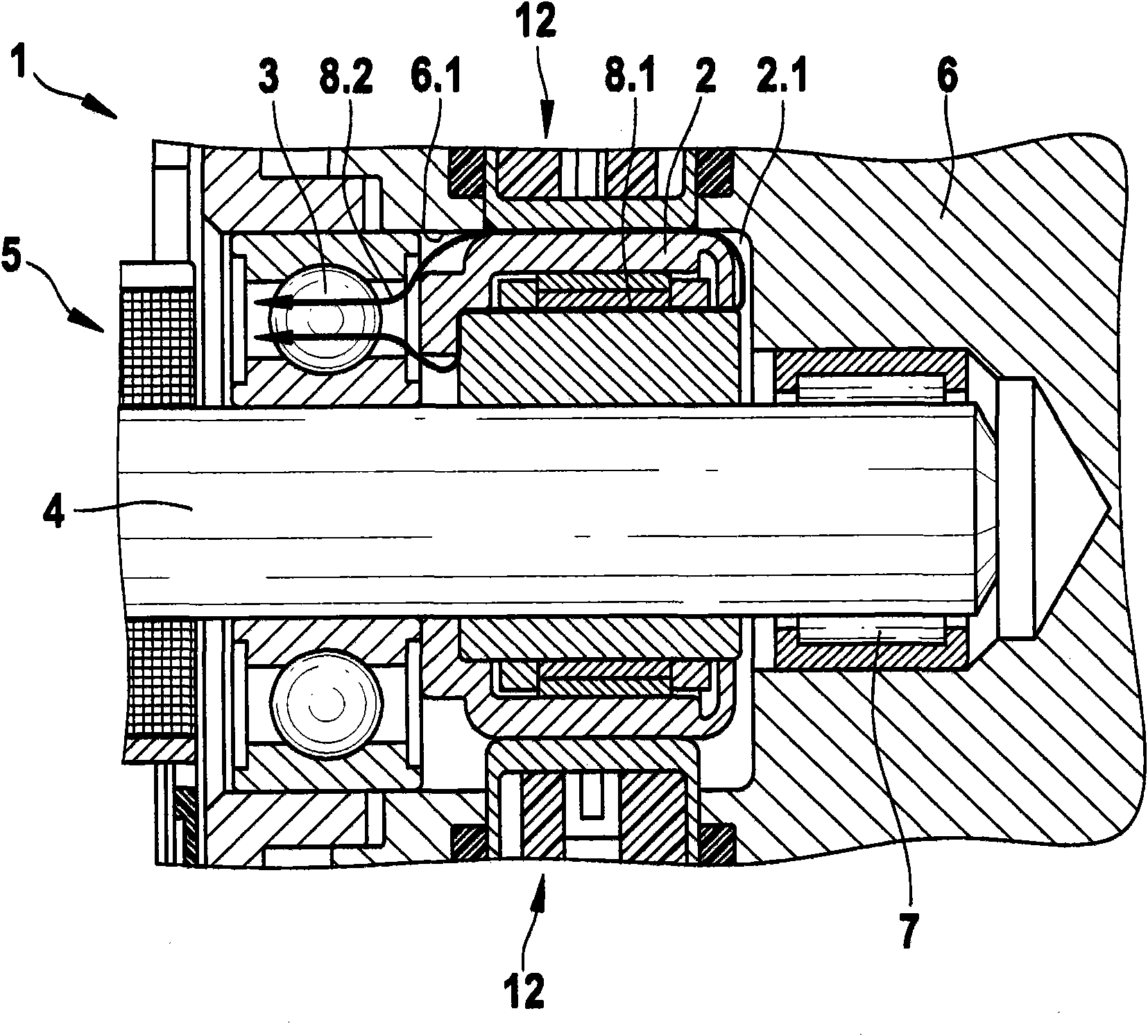

[0018] A conventional pump without compensating section is shown in figure 1 middle. It can be seen that this conventional pump 1 comprises an eccentric bearing 2, a drive bearing 3, a drive shaft 4, a drive motor 5, a pump housing 6 with a motor bore 6.1 and a drive shaft bearing 7. The leakage paths of the pressure medium mentioned at the outset are indicated by arrows 8.1 and 8.2.

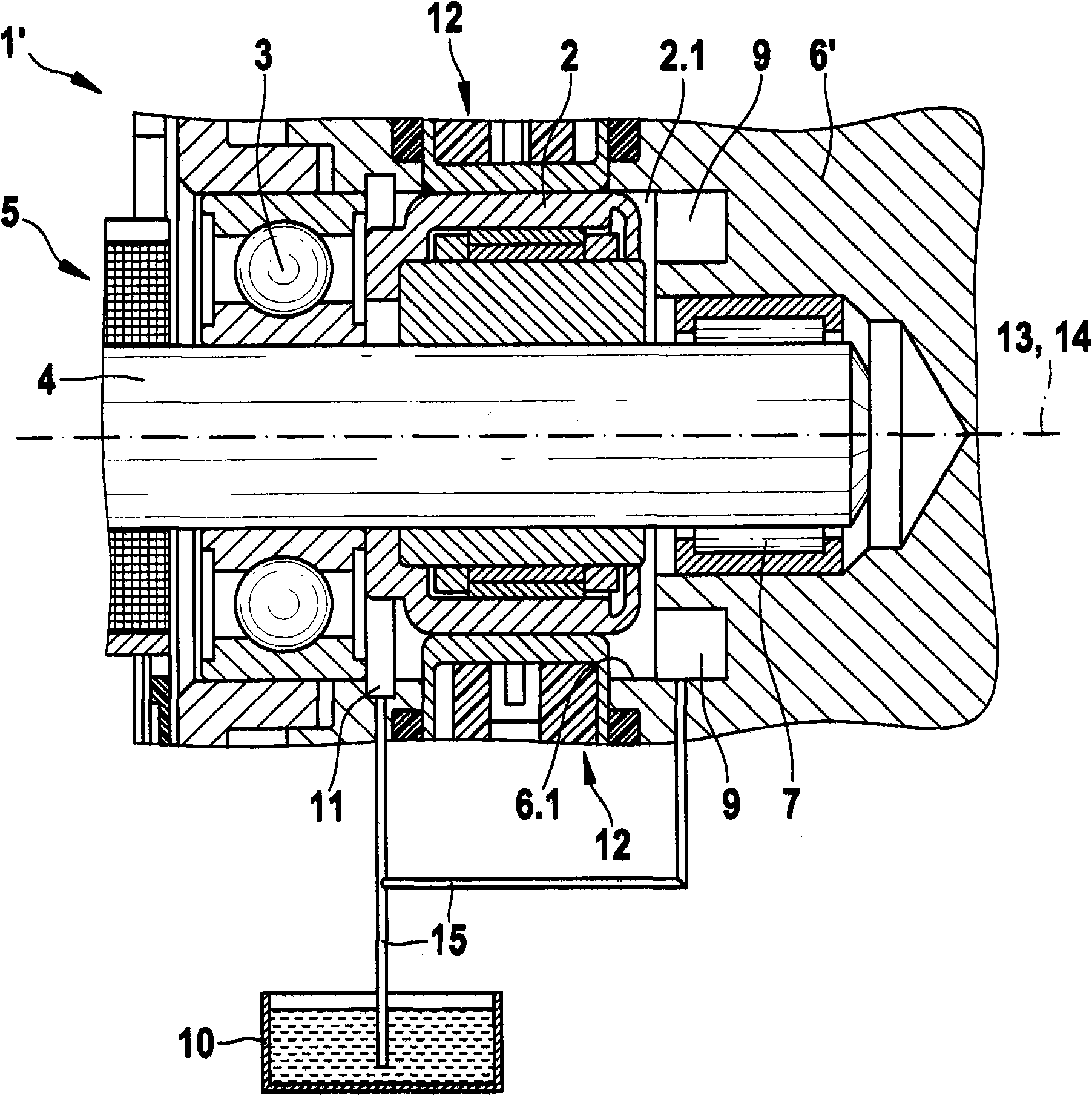

[0019] exist figure 2 Corresponding parts in the same reference numerals are still used. Components improved according to the invention are marked with primes.

[0020] The eccentric bearing 2 and the drive bearing 3 are arranged in the eccentric cavity 2.1 of the pump housing 6'. This eccentric cavity 2.1 is formed by means of a blind hole-shaped motor bore 6.1 on the pump housing 6'. The two pump elements 12 are located in corresponding pump bores of the pump housing 6'. The two pump bores extend radially on both sides of the eccentric cavity 2.1 and lie opposite each other in a straigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com