Arc-extinguishing piece arrangement

A technology of arc extinguishing sheet and switch, which is applied in the direction of electrical components, electric switches, circuits, etc., to achieve good burning resistance and improve the effect of arc extinguishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

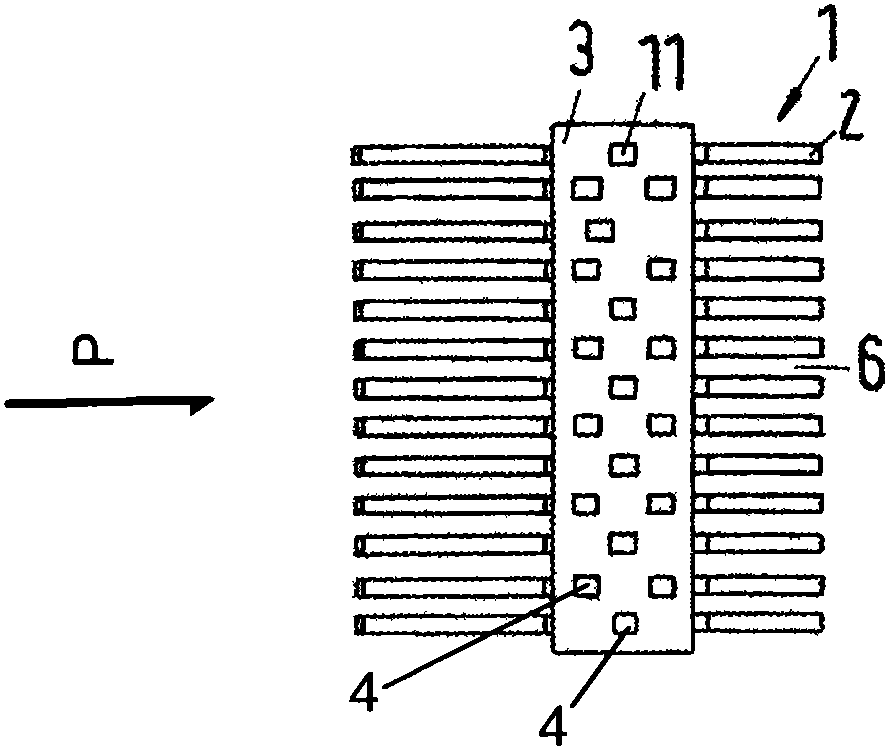

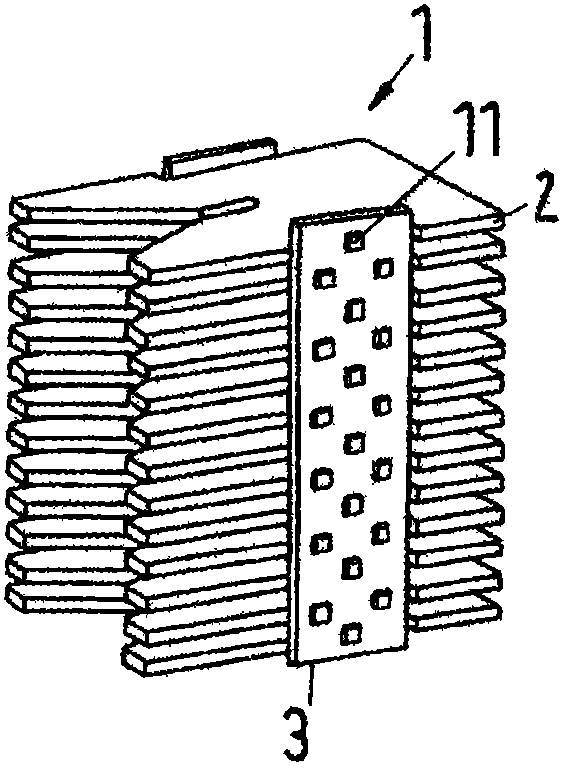

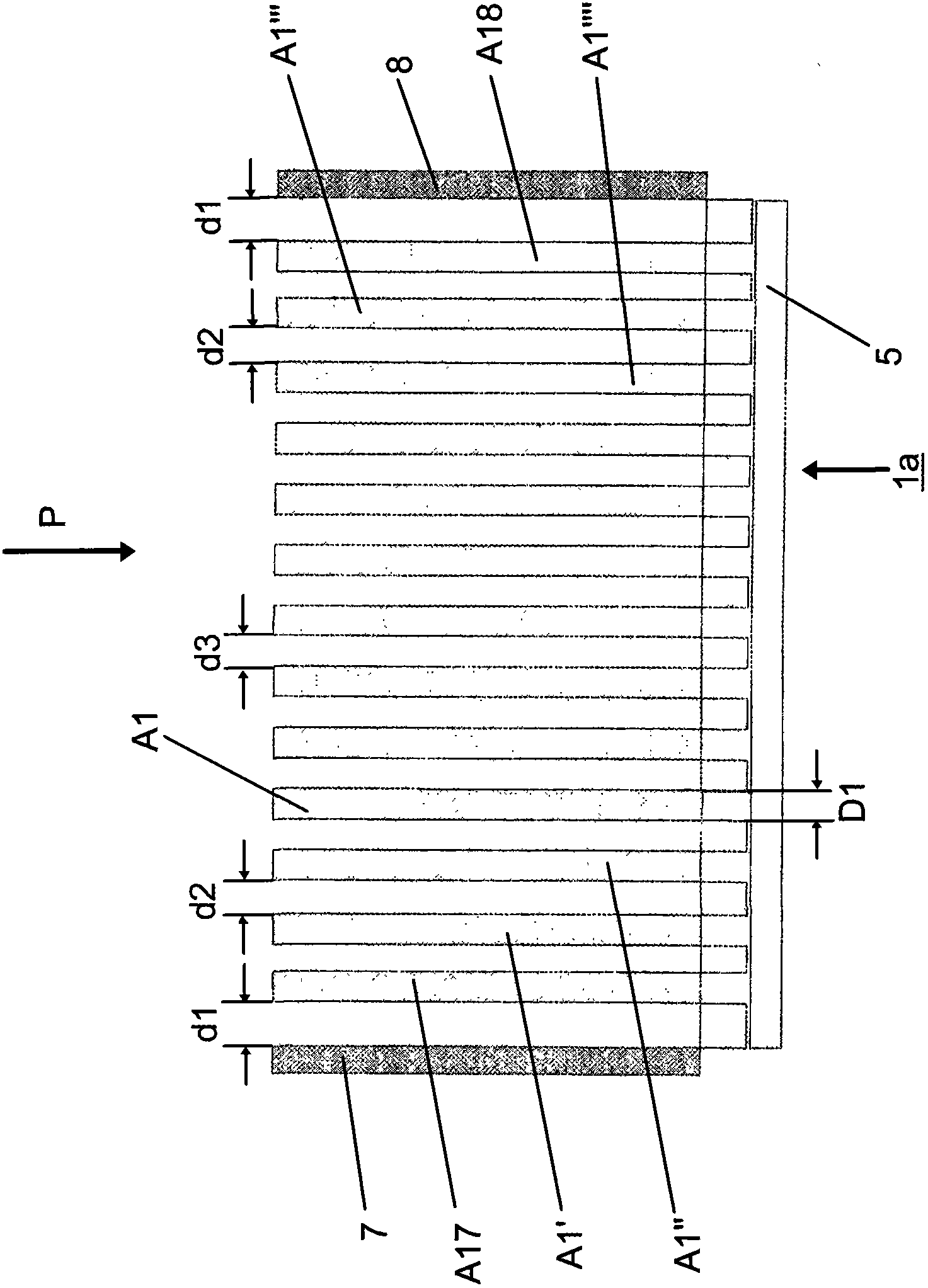

[0040] Figure 1a and Figure 1bA side view and a perspective view of an interrupter arrangement 1 known from the prior art are shown in each case. The individual quenching plates 2 all have the same thickness and the same distance 6 from one another and are connected in the central region by a support means 3 in the form of a support strip 3 . The support strip 3 has a support component 4 in the form of a hole 4 into which a nub-shaped projection 11 engages on the narrow side of the arc extinguisher 2 . As a result, the interrupters 2 are supported by support strips and their mutual spacing is determined. The openings 4 are arranged with a fixed grid size (Rastermass), which is chosen to correspond to the minimum permissible distance between two adjacent quenching plates. Next, alternating one hole and one pair of holes from top to bottom, the arc chute with a single or a pair of existing nubs is applied accordingly. in accordance with Figure 1a and Figure 1b In the emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com