Interactive shearing type cutter structure for food processor

A technology for food processors and crushing knives, which is applied in grain processing, household appliances, kitchen appliances, etc., and can solve the problems of rough food residue, inability to grind, and flow of food liquid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] The present invention is further described below in conjunction with the examples.

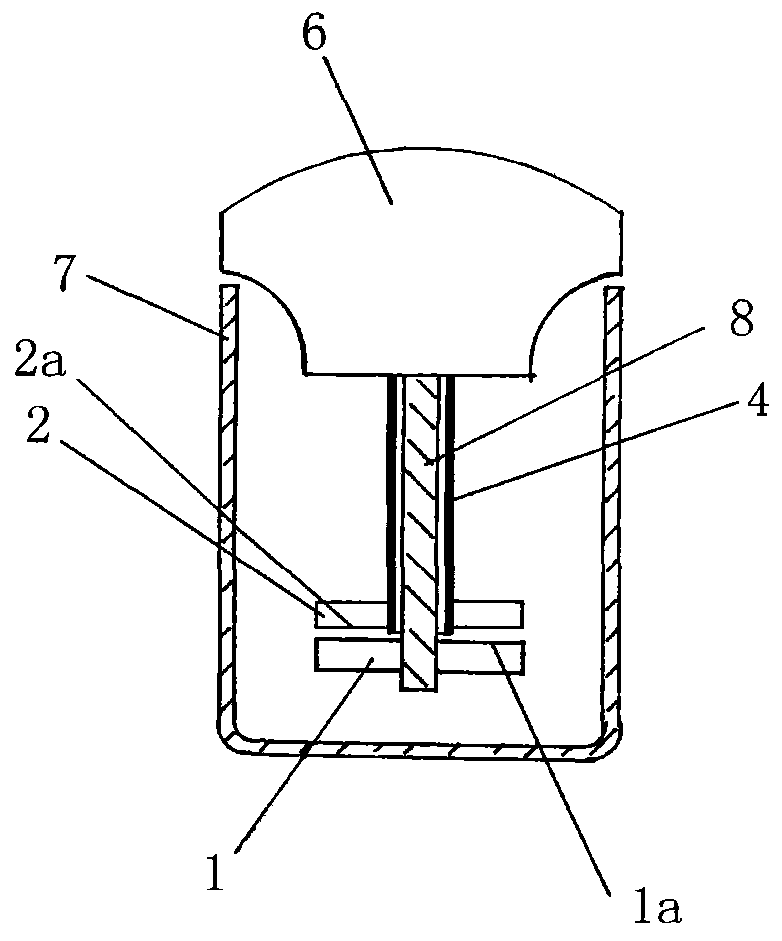

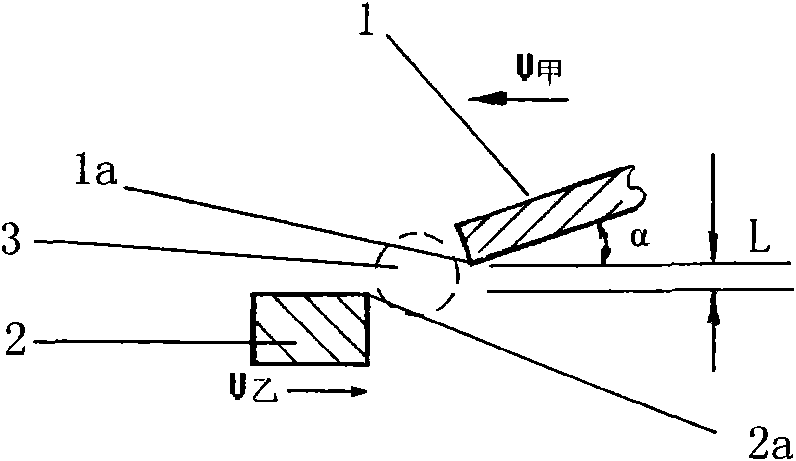

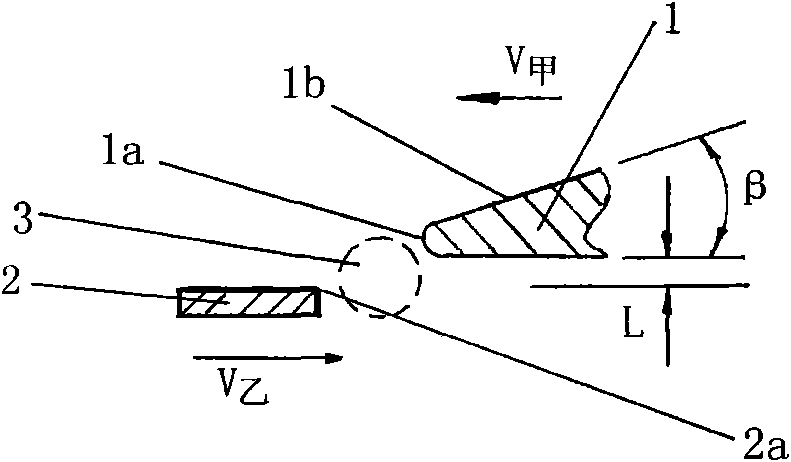

[0085] As shown in the figure, first scissors cutter body 1; second scissors cutter body 2; food material 3 (dotted line ball); second power shaft 4; machine head 6; barrel body 7; first power shaft 8; guide tube 9; barrel Bottom 13; base 66;

[0086] The edge 1a of the first scissors blade body 1; the rake face 1b of the first scissors blade body 1; the upper cover 1c of the first scissors blade body 1; the working hole 1f of the first scissors blade body 1;

[0087] The knife edge 2a of the second scissors knife body 2; the upper cover 2c of the second scissors knife body 2; the working hole 2f of the second scissors knife body 2;

[0088] The lower end face 9a of the guide tube 9; the upper end face 9b of the guide tube 9.

[0089] The parameters of the present invention are defined as follows:

[0090] α: Angle between the body (wing) of the first scissors and the rotating surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com