Conveying device

A technology for conveying devices and transmission belts, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., which can solve problems such as excessive time spent, wear of conveying rollers, damage to glass substrates, etc., to reduce maintenance costs and time, and increase conveying speed , Reduce the effect of rolling friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

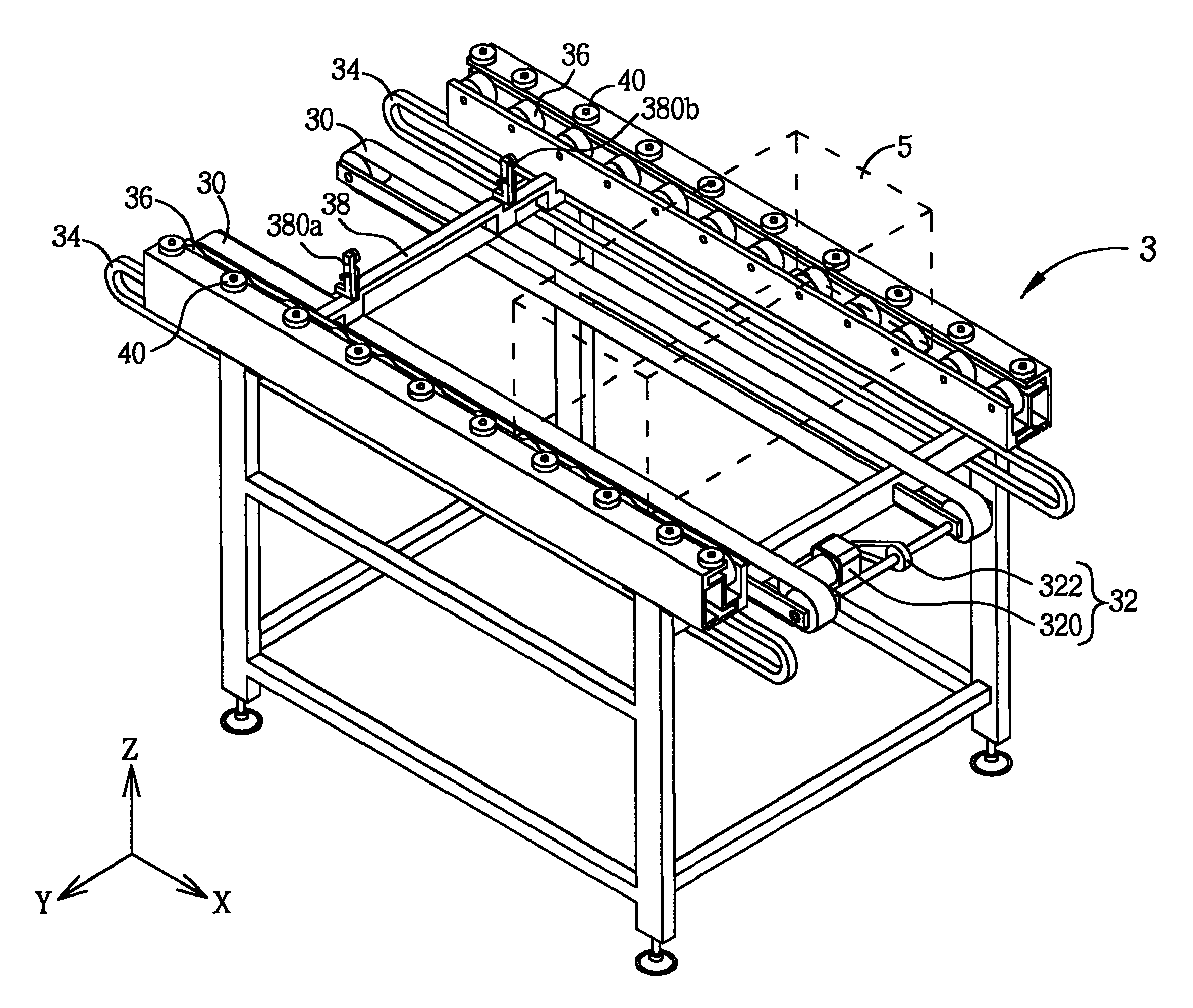

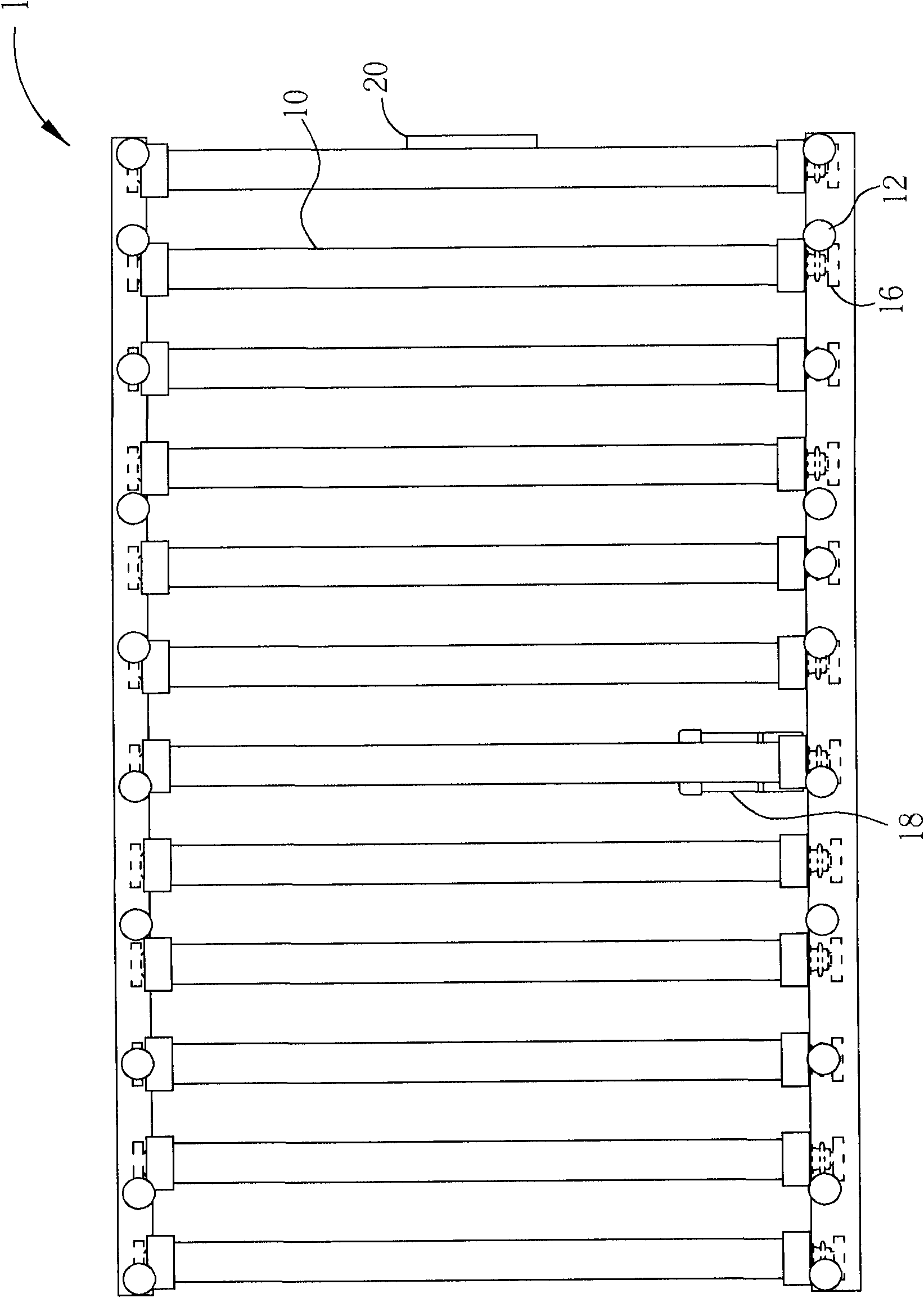

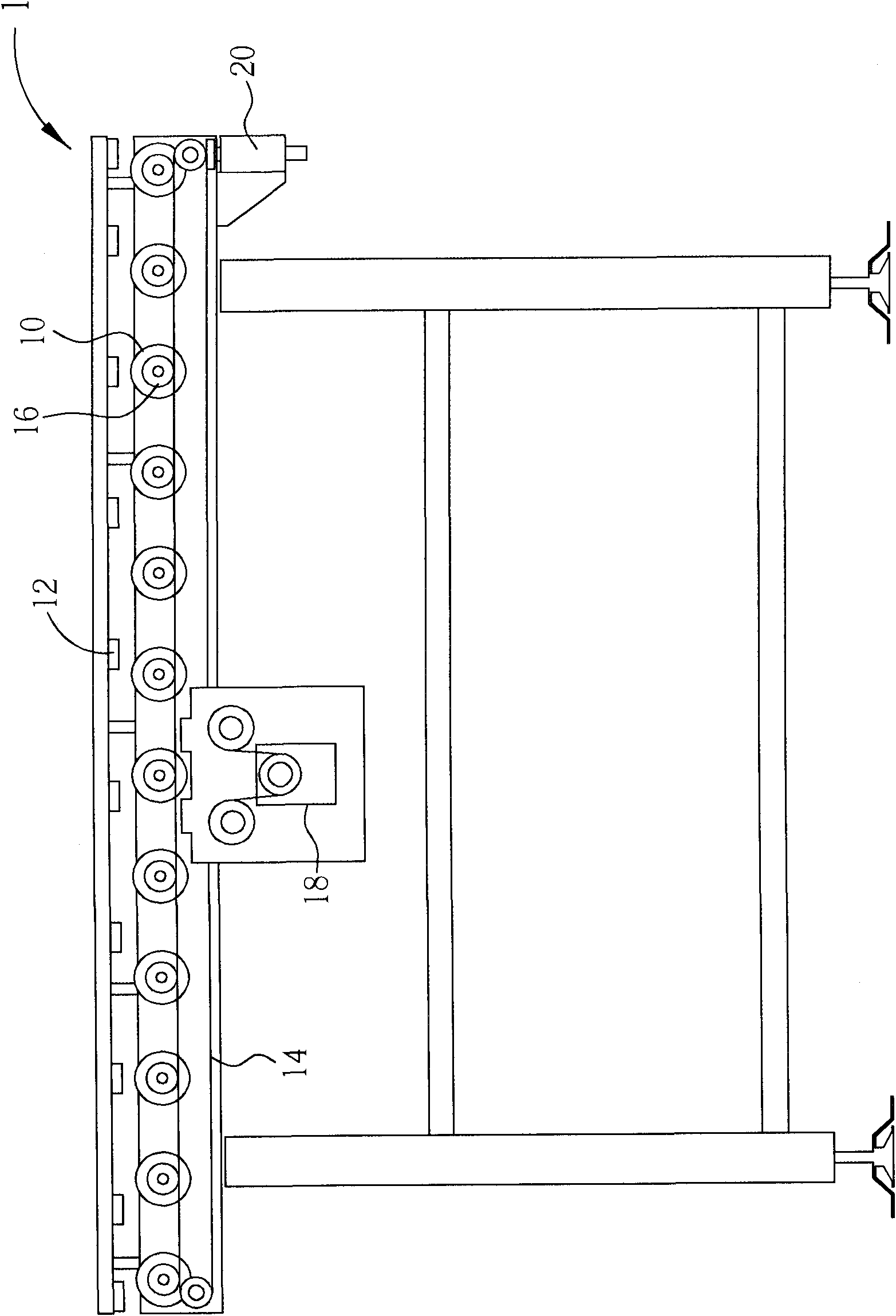

[0043] Please refer to FIG. 3 and FIG. 4 , FIG. 3 is a perspective view of the delivery device 3 according to an embodiment of the present invention, and FIG. 4 is a top view of the delivery device 3 in FIG. 3 . As shown in FIGS. 3 and 4 , the conveying device 3 includes two transmission belts 30 , a driving mechanism 32 , two guide rails 34 , a plurality of first rollers 36 , a first pushing platform 38 and a plurality of second rollers 40 . The driving mechanism 32 is connected to the transmission belt 30 for driving the transmission belt 30 . In this embodiment, the driving mechanism 32 may include a motor 320 and a connecting rod 322 , wherein the connecting rod 322 is connected to one end of the transmission belt 30 , and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com