Double-stage double-acting hydraulic cylinder for lateral dump truck in railway

A double-acting hydraulic cylinder and dump truck technology, applied in the field of double-stage hydraulic cylinders, can solve the problems of energy waste, car box disengagement, small lifting force, etc., and achieve the effects of improving unloading safety, reducing the height of the center of gravity, and ensuring the sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

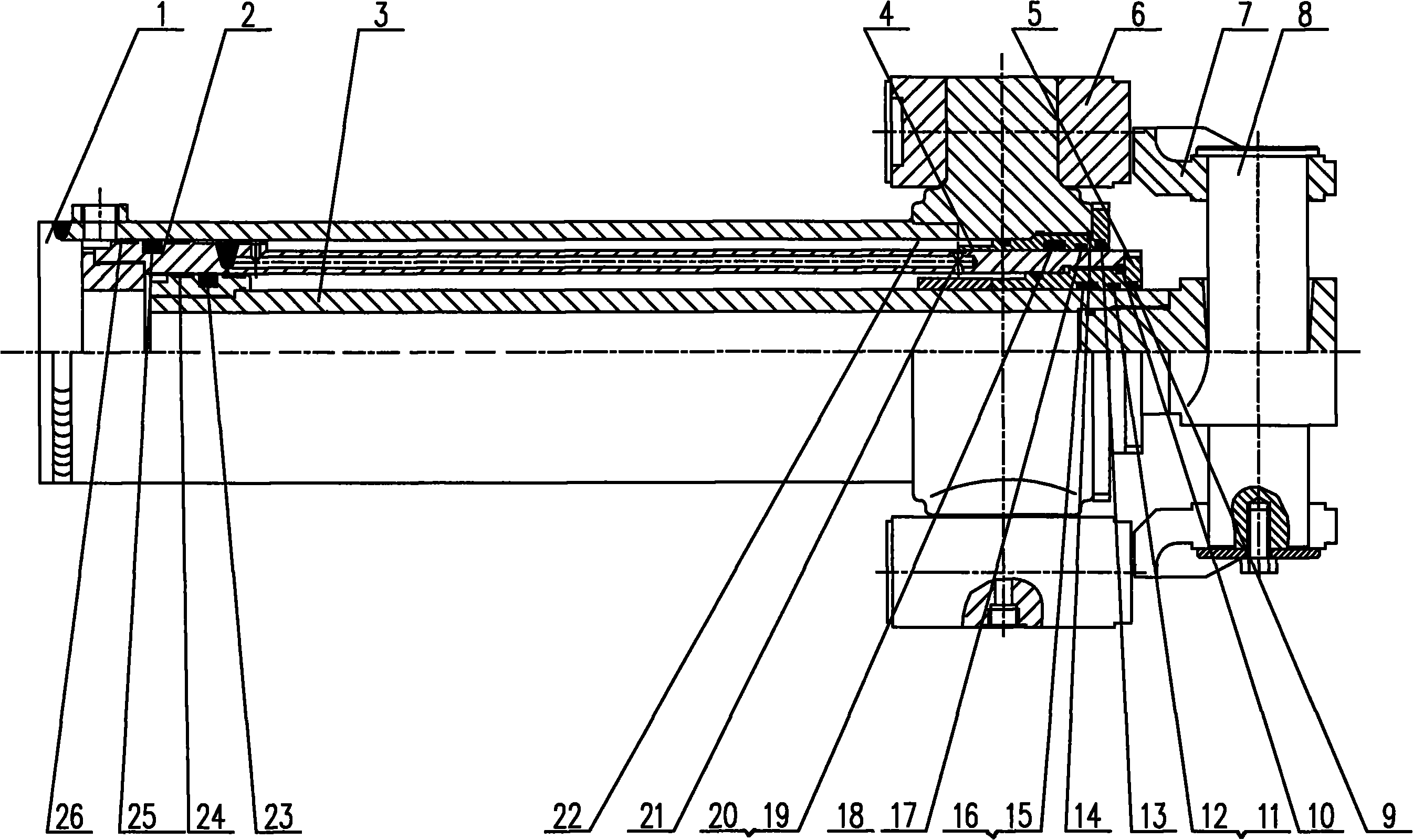

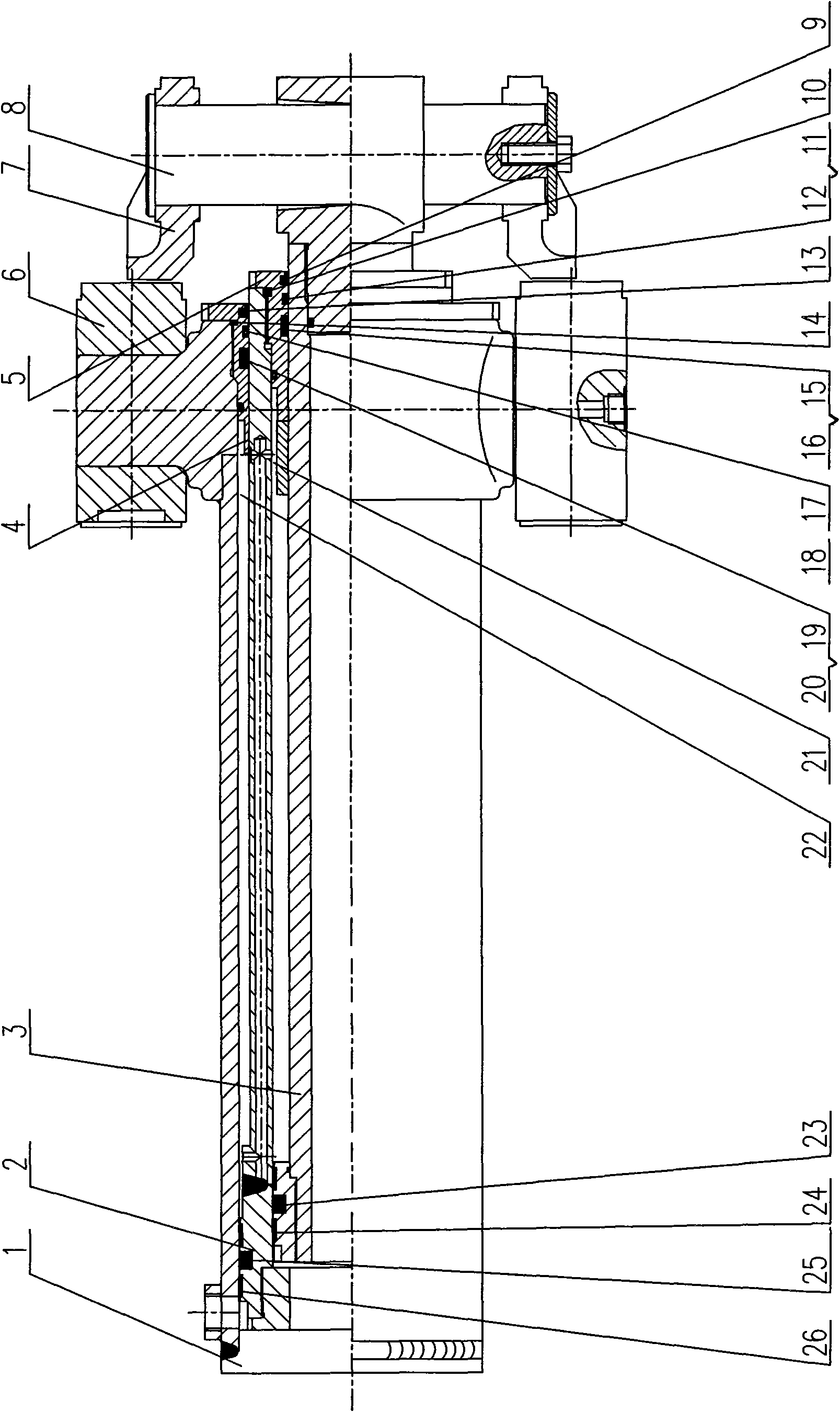

[0017] The double-stage double-acting hydraulic cylinder of the railway side dump truck consists of: an outer cylinder body 1 installed on the oil cylinder bearing seat 6, and the outer cylinder body 1 passes through the outer support ring 26, the outer combined seal 25 and the outer guide The sleeve 4 is connected to the inner cylinder body 2;

[0018] The inner cylinder body 2 is connected to the piston rod 3 through the inner support ring 24, the inner combination seal 23 and the inner guide sleeve 5;

[0019] The other end of the piston rod 3 cooperates with the top iron shaft 8, and the toe iron 7 is housed on the top iron shaft 8.

[0020] The KF-100 100-ton side dump truck is loaded with the above-mentioned products. The top iron shaft is connected to the top iron seat of the side dump truck box, and the oil cylinder bearing seat is connected to the bottom beam of the side dump truck to form a supporting seat. After testing, the vehicle is in good condition for use and...

Embodiment 2

[0022] The double-stage double-acting hydraulic cylinder of the railway side dump truck described in Embodiment 1, wherein the outer combined seal includes: O-ring 17 , back-up ring 18 , sealing ring 19 , back-up ring 20 and dust-proof ring 13 .

[0023] The inner combination seal described therein includes: O-ring 11 , retaining ring 12 , sealing ring 15 , retaining ring 16 and dustproof ring 9 .

Embodiment 3

[0025] In the double-stage double-acting hydraulic cylinder of the railway side dump truck described in embodiment 1 or 2, the outer side of the outer guide sleeve 4 is in contact with the outer cylinder body 1 through the O-ring 14 and the thread, and the inner guide sleeve 5. The outer side is in contact with the inner cylinder body 2 through the O-ring 10 and the thread.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com