Movable electric furnace coal injection method for replacing coke w anthracite in electrosmelting by fire method

A technology for electric furnace smelting and anthracite, which is applied to furnaces, furnace components, charge control, etc., can solve the problems of large volume, uneven distribution of oxygen content, low reduction reaction efficiency, etc., and achieves the effect of saving electric energy and coke.

Inactive Publication Date: 2010-08-25

牛庆君

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Existing electric furnaces for smelting copper, nickel, iron alloys, calcium carbide, etc. are usually bulky, and three-phase electrodes are inserted in the furnace, which are roughly distributed in an equilateral triangle. The distribution of oxygen content is very inhomogeneous, resulting in inefficient localized reduction reactions

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

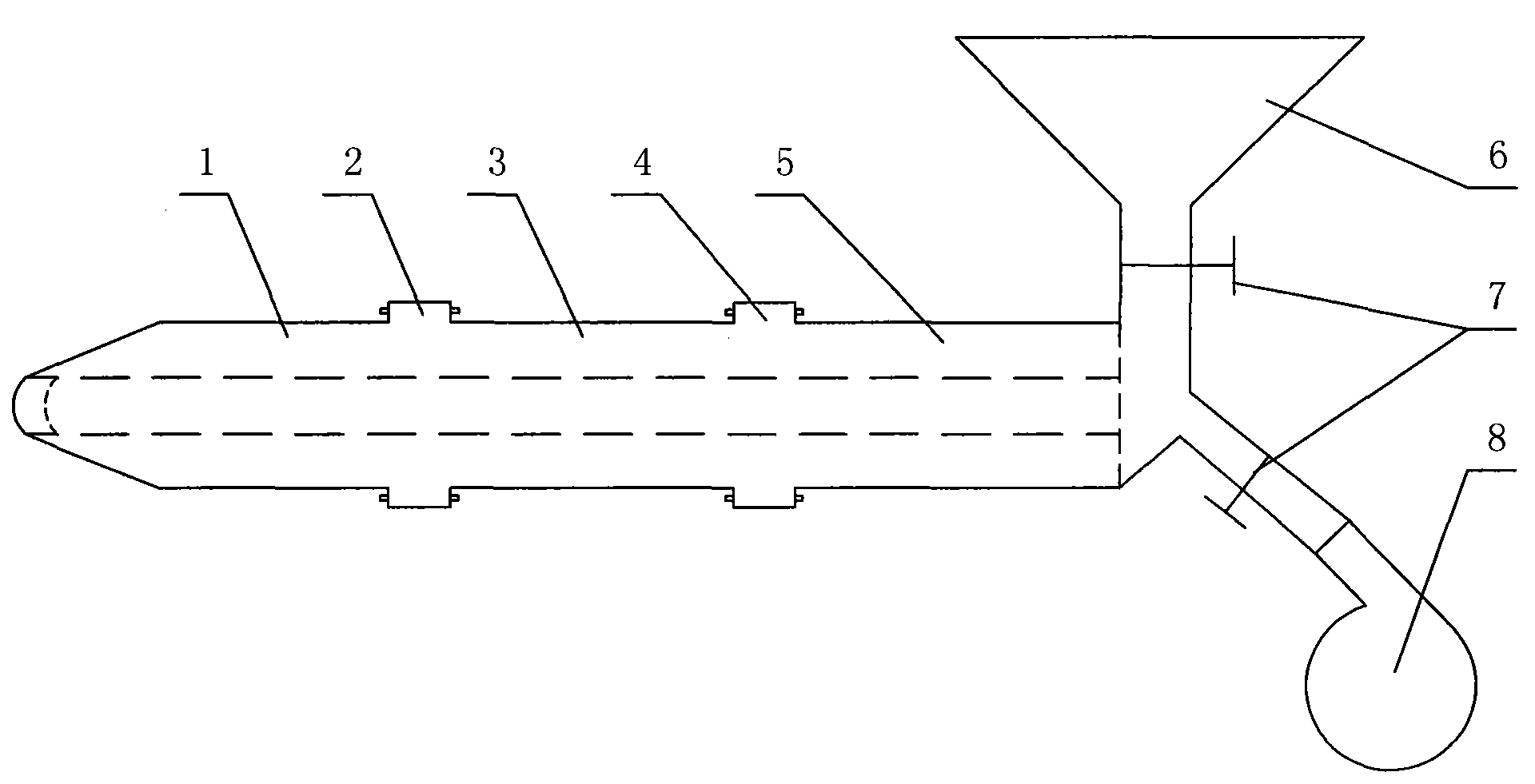

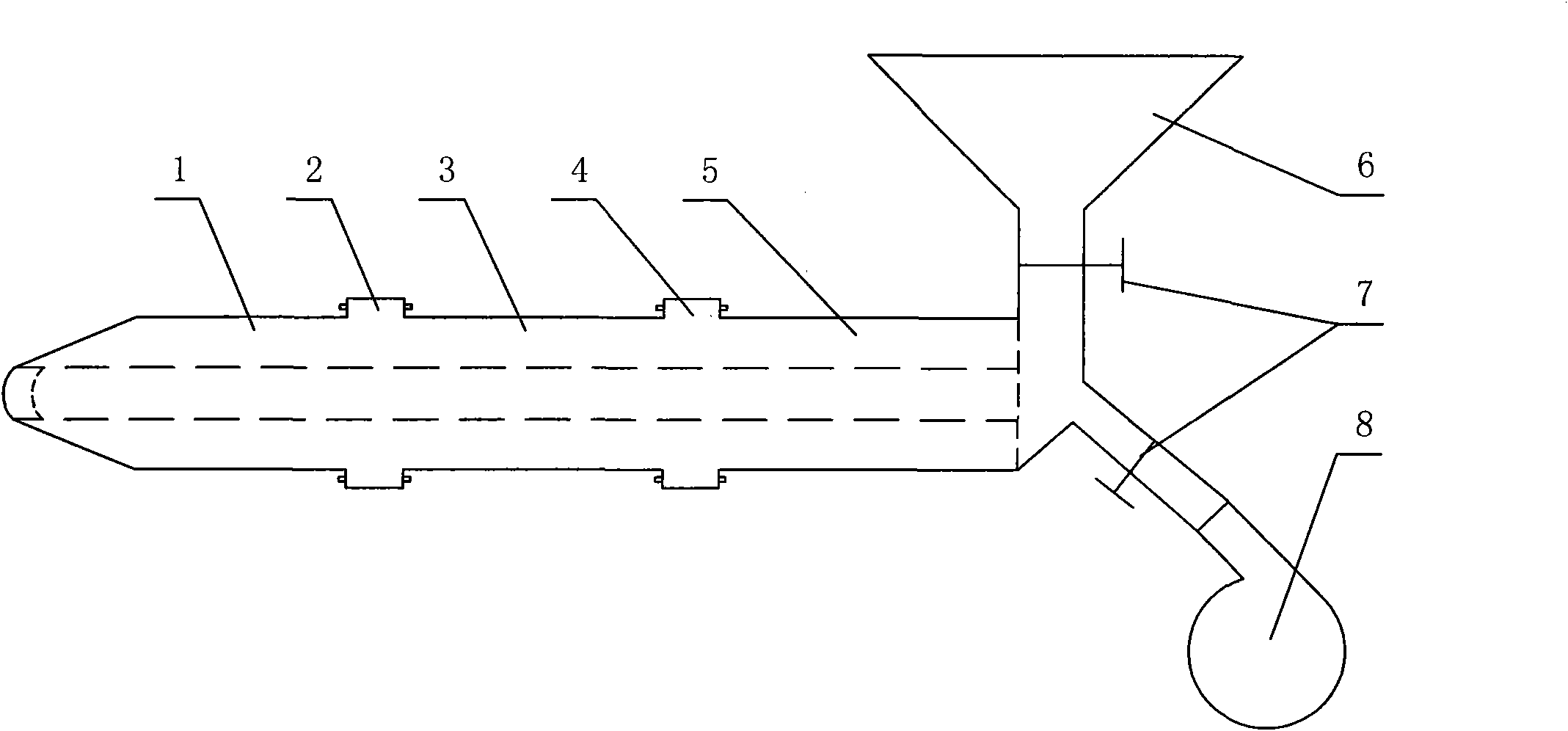

The invention relates to a technology and equipment used in fire ore-smelting electric furnace smelting production, in particular to a movable electric furnace coal injection method for replacing coke by anthracite in electrosmelting by a fire method. The method is characterized in that when raw materials in a smelting furnace is heated to a fusion state, a mixture of anthracite powder and air or a mixture of anthracite powder and oxygen is added below the liquid level in the furnace. The invention is obviously suitable for all production technologies adopting electric furnaces for smelting and needing carbonaceous raw materials, thereby saving electric energy and coke.

Description

Coal injection method of mobile electric furnace using anthracite instead of coke in pyroelectric furnace smelting technical field The invention relates to a technology and equipment in the smelting and production of pyrothermal electric furnaces, in particular to a coal injection method for a mobile electric furnace in which anthracite is used instead of coke in the pyroelectric furnace smelting. Background technique Pyrometallurgy refers to various operations that use fuel, electric energy or other energy sources to generate high temperatures, and use metallurgical furnaces at high temperatures to separate valuable metals from a large number of gangues in concentrates. Also known as pyrometallurgy, it is a metallurgical process that uses high temperature to extract metals or metal compounds from ores, and is the main method of metallurgy. In this process, no aqueous solution participates in the reaction, so it is also called dry metallurgy. It is mainly used in iron and...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F27D3/18

Inventor 牛庆君

Owner 牛庆君

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com