Detection device for load of rolling bearing and detection method thereof

A rolling bearing and testing device technology, applied in the direction of mechanical bearing testing, etc., can solve the problem of no rolling bearing dynamic load testing, etc., to save testing time, improve testing efficiency, and facilitate installation and disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

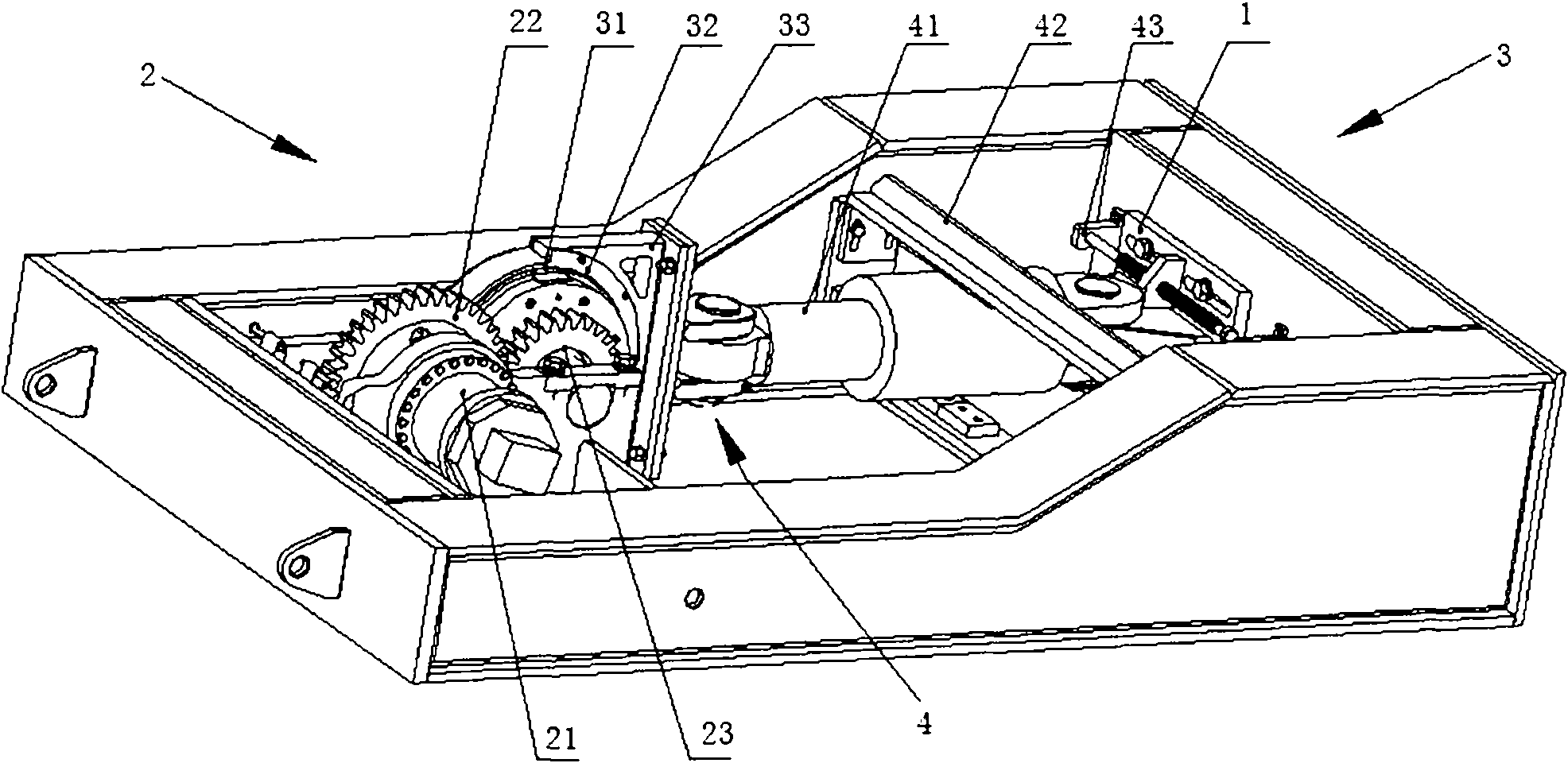

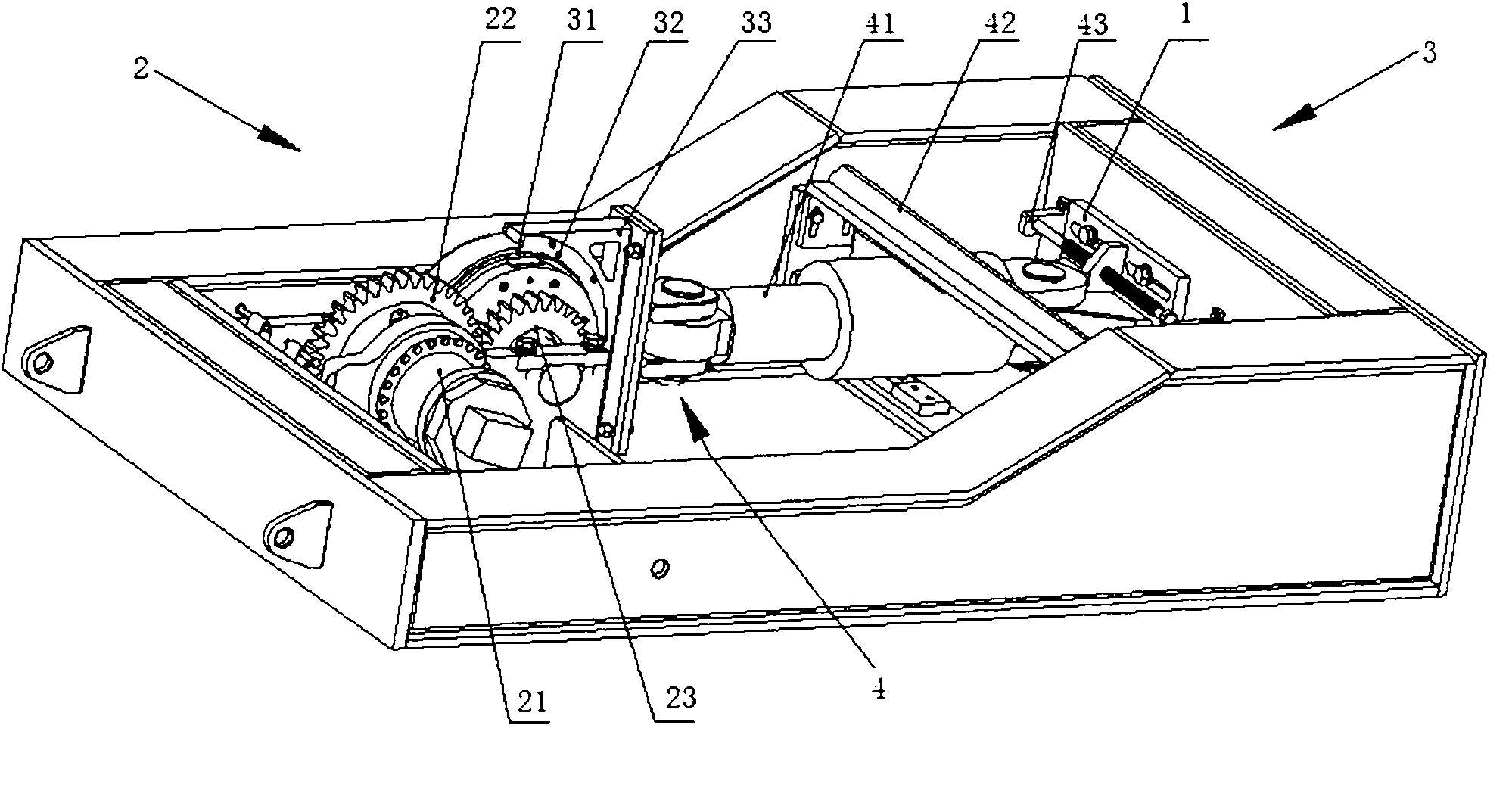

[0034] Embodiment 1: Please refer to Fig. 1, a rolling bearing load detection device, including a base 1, a power transmission mechanism 2 arranged at the front end of the base 1, a connection connected to the power transmission mechanism 2 and arranged behind the power transmission mechanism 2 The mechanism 3 and the loading mechanism 4; The power transmission mechanism 2 includes a hydraulic motor 21, a large gear 22 and a small gear 23; the rotating shaft of the hydraulic motor 21 is connected with the large gear 22 to drive the large gear 22 to rotate; the large gear 22 and the small gear 23 are meshed and connected, and the large gear 22 drives the small gear 23 turns. The connection mechanism 3 includes a bearing sleeve 31 , a copper lining 32 arranged above the bearing sleeve 31 and moving relative to the bearing sleeve 31 , and a pressing plate 33 connected with the copper lining 23 . The pinion 23 is connected with the bearing sleeve 31 by a key, and the pinion 23 dr...

Embodiment 2

[0046] Embodiment 2: As shown in Figure 1, the hydraulic motor 21 installed on the base 1 is driven to rotate by the hydraulic pump station, driving the large gear 22, and then pushing the pinion 23 to rotate; the pinion 23 is rigidly connected with the bearing sleeve 31, thereby driving Bearing sleeve 31 rotates. The bearing sleeve 31 will rotate synchronously with the outer ring of the bearing, and its speed is equal to that of the pinion 23 .

[0047] While the bearing is rotating, the oil cylinder 41 also applies a radial load to the bearing. The load applied by the oil cylinder 41 acts on the copper lining 32 that rotates relative to the outer ring of the bearing sleeve 31 through the pressure block 33. The overall structure is similar to a sliding bearing, and the static load of the oil cylinder 41 is transmitted and evenly distributed and acts on the outer ring of the bearing. On the ring, instead of point contact and line contact, it can not only apply a unidirectiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com