High-alkaline double-alkali simplified desulfuration control method by adding agent at front end of canal

A technology with simplified control and high alkalinity, which is applied in chemical instruments and methods, separation methods, and separation of dispersed particles. It can solve the difficulty of injection volume, and the technical advantages of high efficiency and energy saving of double-alkali desulfurization process are difficult to achieve. There are many changing parameters to achieve the effect of simplifying the control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

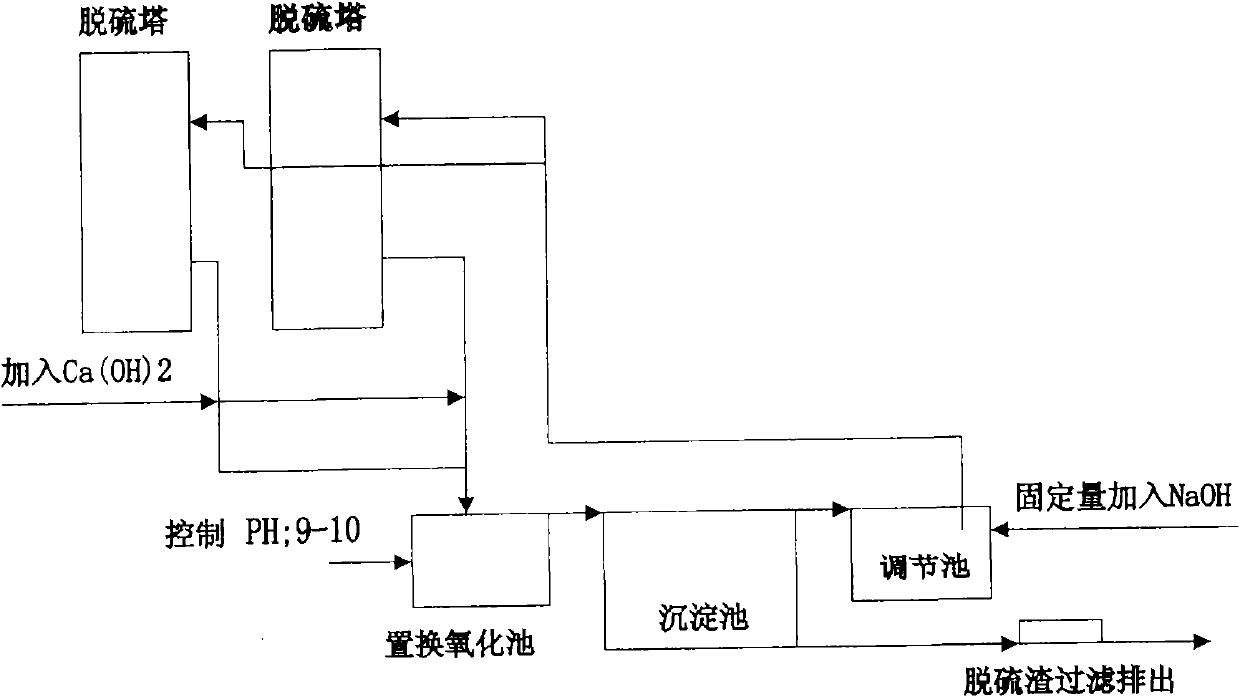

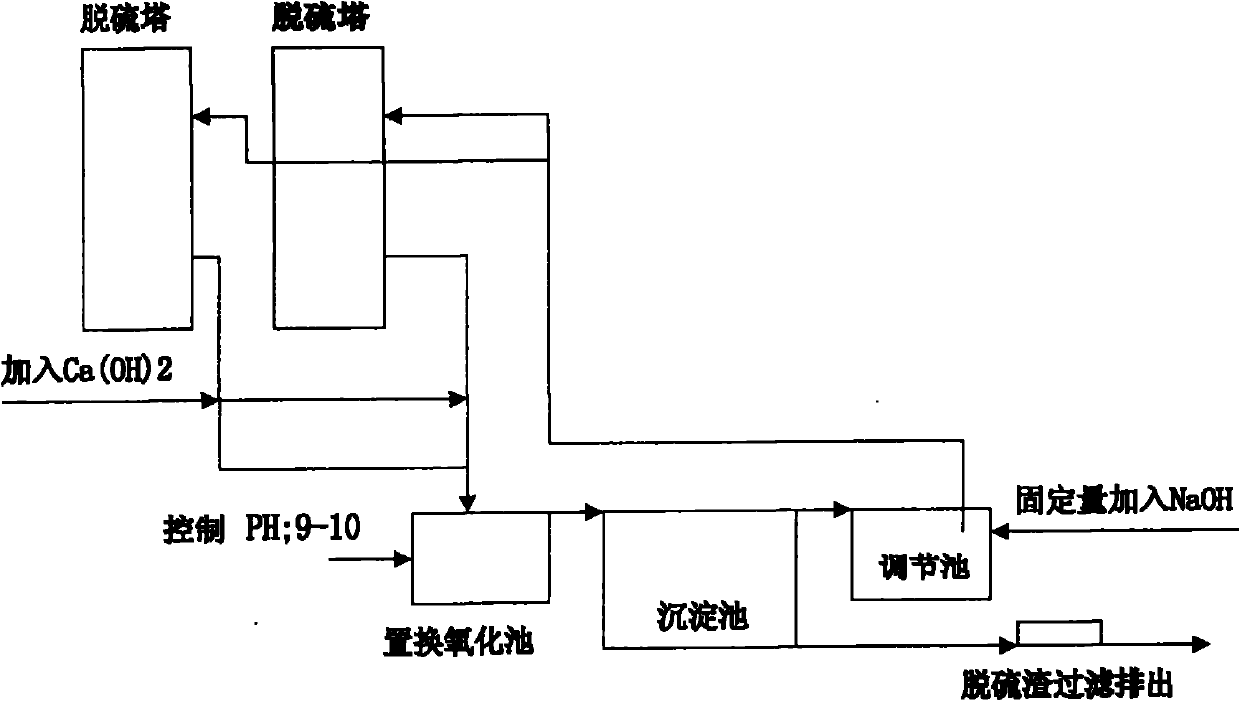

Image

Examples

Embodiment 1

[0012] The technical focus of this method is to control the loss of NaOH during the circulation process and always ensure that a sufficient amount of NaOH participates in the desulfurization reaction.

[0013] There are two ways for the loss of NaOH, one is to be taken away by the desulfurization waste liquid, and the other is to be oxidized into desulfurization sodium (NaOH 2 SO 4 ) and cannot be restored.

[0014] The first loss of NaOH is unavoidable, because the discharged desulfurization slag must contain a certain amount of liquid. This loss does not have to be controlled, it just has to be taken into account when calculating the cost.

[0015] The second loss must take measures to control. The method has two aspects:

[0016] One is to inject Ca(OH) 2 The position of the solution should be as close as possible to the outlet of the desulfurization tower (for multiple desulfurization towers, it can be injected at the outlet of each tower separately), so that it can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com