Cleaning machine

A cleaning machine and air compressor technology, applied in the field of cleaning machines, can solve the problems of damage to cleaning objects, large water consumption, small cleaning area, etc., and achieve the effect of saving water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

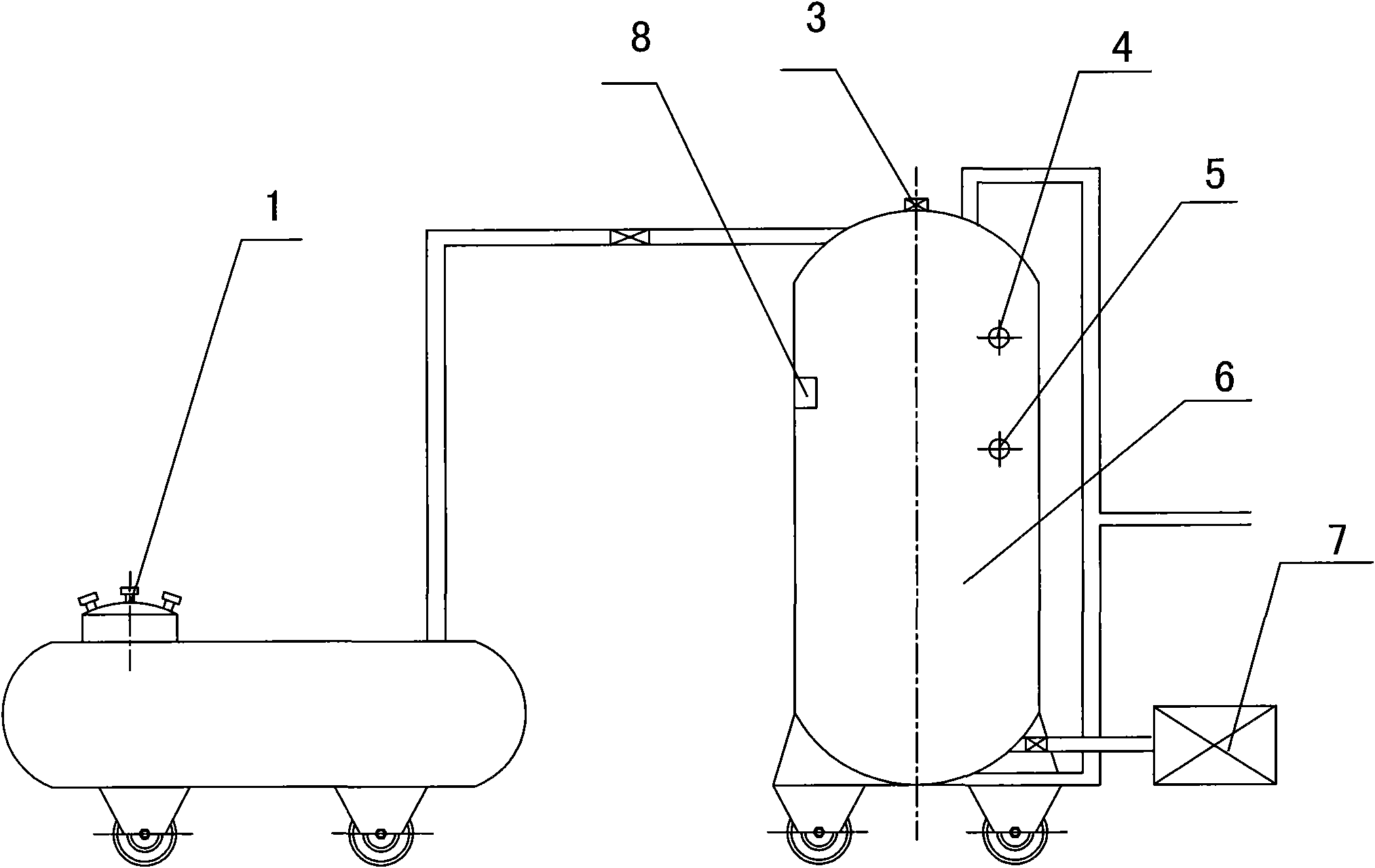

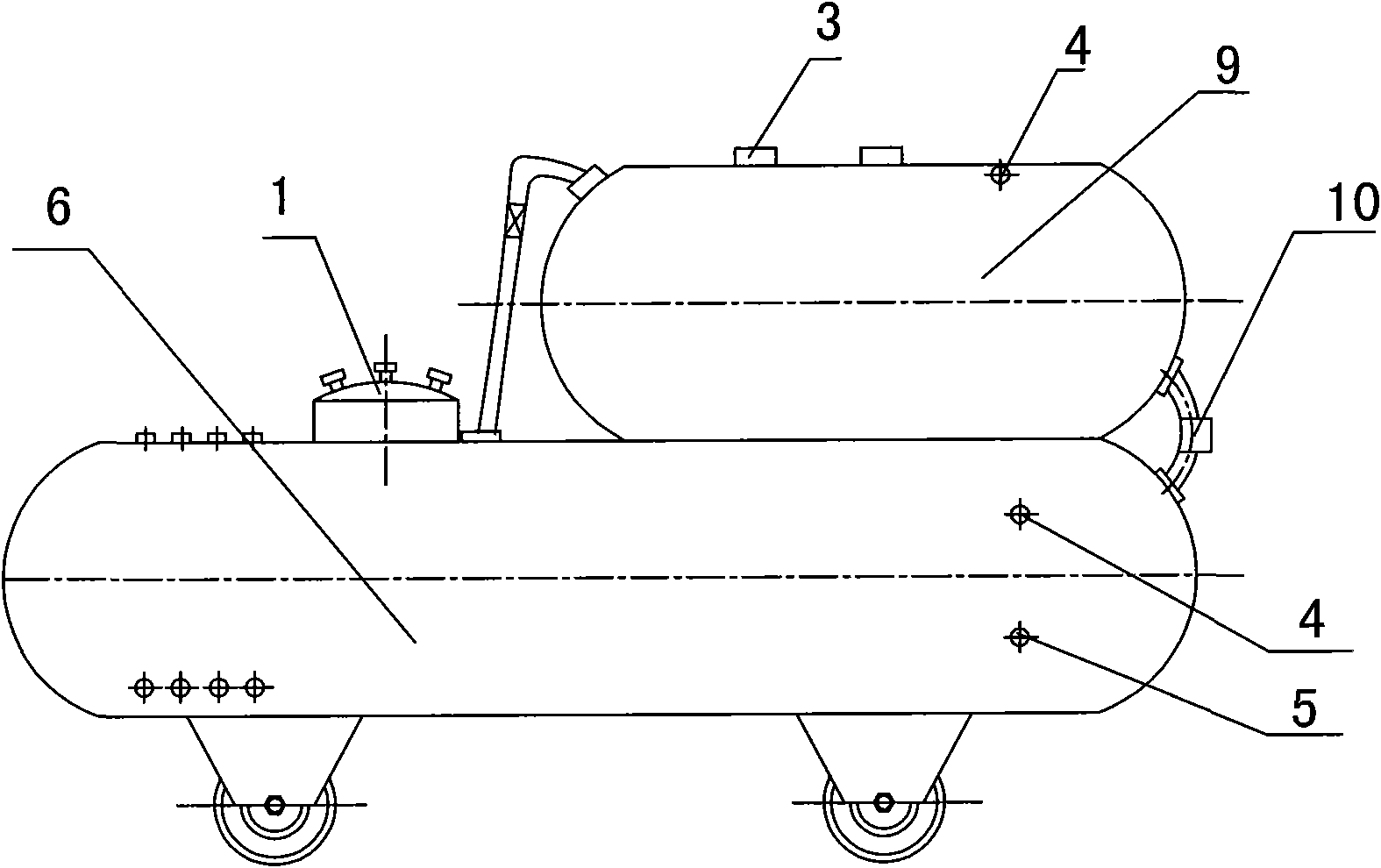

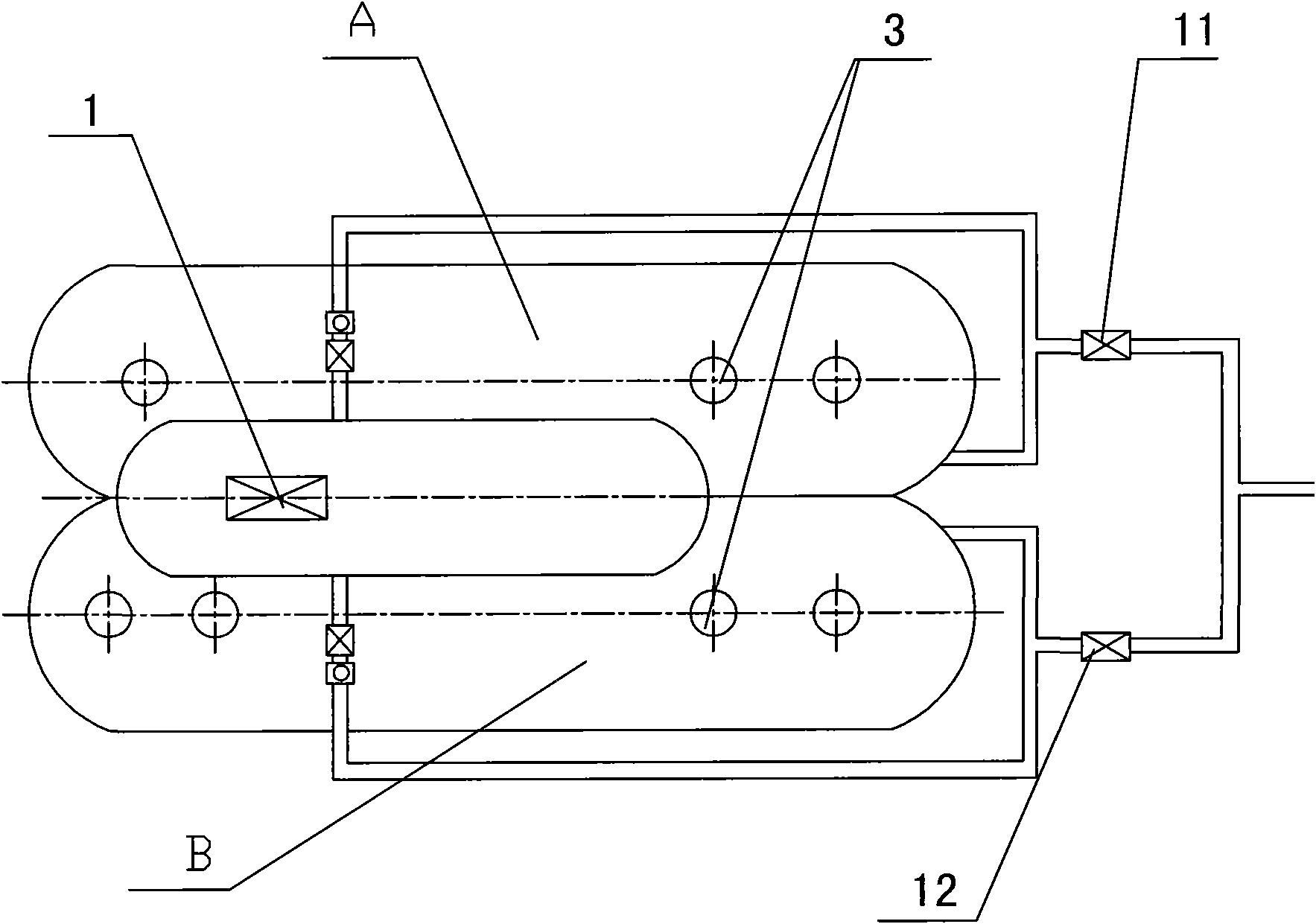

[0010] Accompanying drawing has shown structure of the present invention and embodiment thereof, further describe relevant detail and working principle of its embodiment below in conjunction with accompanying drawing: this kind cleaning machine comprises water storage tank 6, the water inlet of described water storage tank 6 The water outlet of the water storage tank 6 is connected with the water gun through the pipeline through the high-pressure water pump 7, and the water storage tank 6 is also connected with the air compressor 1 through the pipeline, and a control system is provided on the connected pipeline. Valve 2, the water storage tank 6 is provided with an upper water level switch 4, a lower water level switch 5 and an exhaust valve 2, and the upper water level switch 4 and the lower water level switch 5 are all connected with the high pressure water pump 7 and the exhaust valve 3. When the present invention will clean the automobile, if the original water level does n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com