Rotating-shaft lip-shaped seal ring framework deviation-resisting compacting mold

A technology for lip seals and pressing molds, which is applied to household appliances, other household appliances, household components, etc. It can solve problems such as misalignment, burning, and unreasonable structure of skeleton oil seal pressing molds, so as to eliminate offset defects, The effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

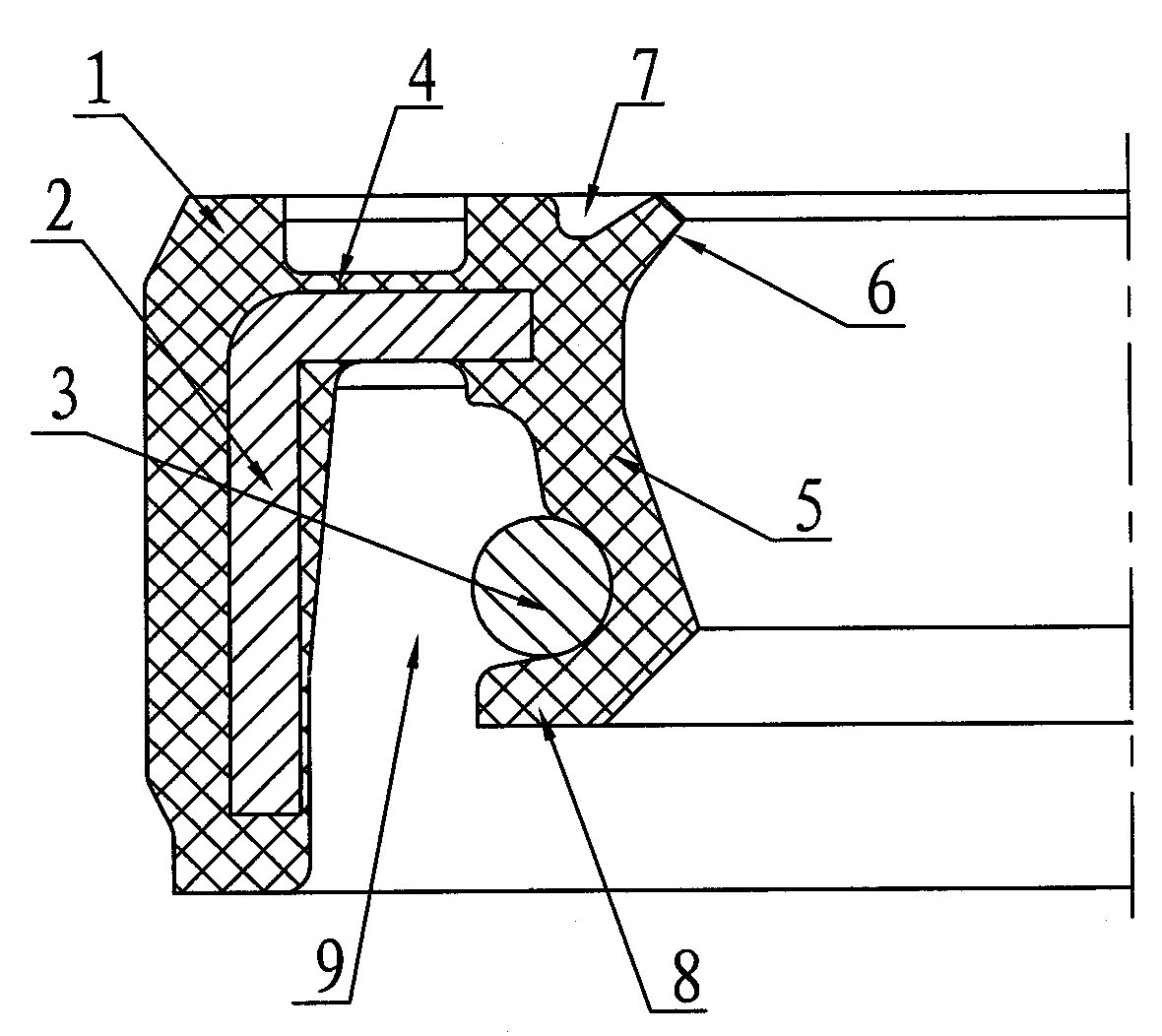

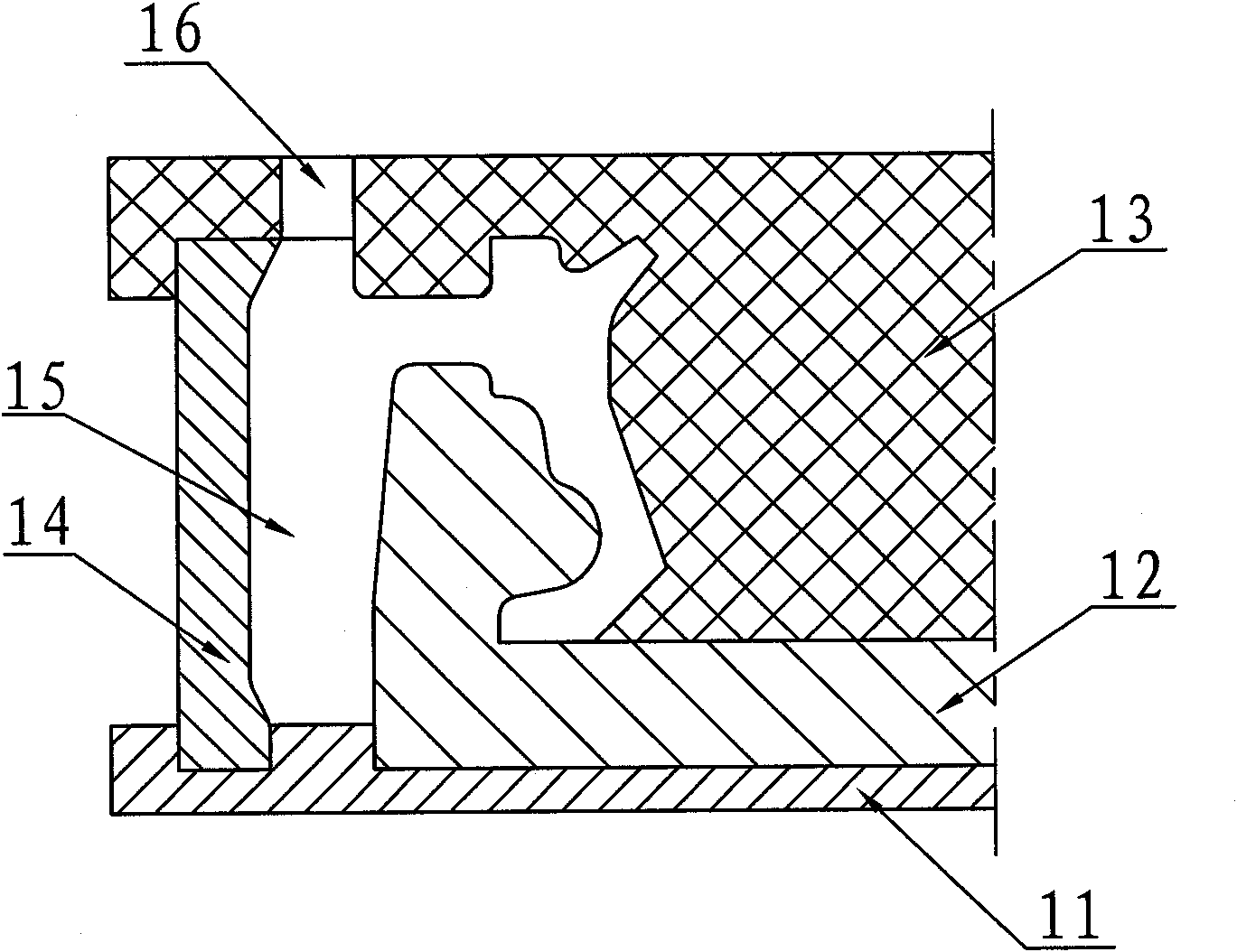

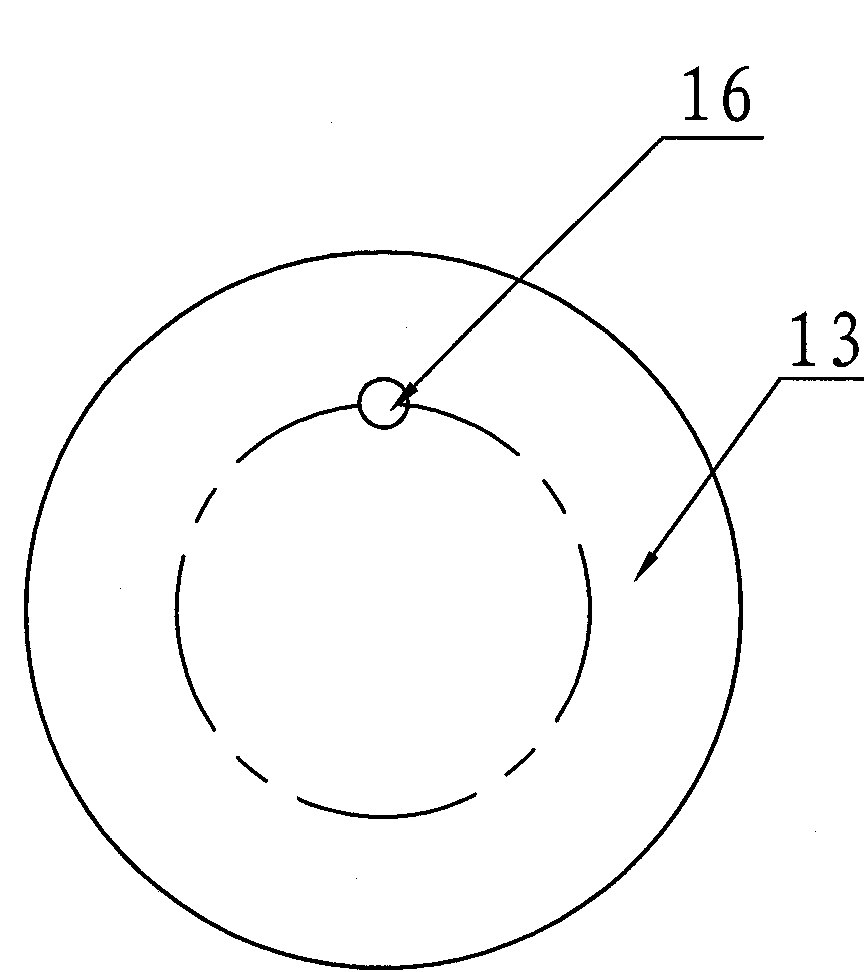

[0017] A rotary shaft lip seal ring skeleton anti-bias pressing mold, which is composed of a lower mold plate 11, a lower mold core 12, an upper mold core 13 and a mold sleeve 14, the lower mold core 12 is fixedly installed on the lower mold plate 11, and the mold sleeve 14 is positioned Fixedly installed on the lower template 11, the upper mold core 13 is located above the lower mold core 12 and the mold sleeve 14, and the upper mold core 13 cooperates with the mold sleeve 14 through the positioning notch to ensure that the lower mold core 12, the upper mold core 13 and the mold sleeve 14 The correctness of the relative position forms an oil seal cavity 15 with the same cross-sectional shape as the skeleton oil seal to be pressed, and three glue injection holes 16 are evenly arranged on the same circumference of the upper end surface of the upper mold core 13, and three glue injection holes 16 are all in communication with the oil seal mold cavity 15; on the outer cylindrical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com