A kind of manufacturing method of wing body fusion honeycomb sandwich composite material skin

A composite material and wing body fusion technology, applied in the field of composite material molding in the aviation industry, can solve the problems of difficult control of honeycomb edges, high cost, complex skin shape, etc., to eliminate honeycomb core offset defects, reduce curing costs, The effect of shortening the curing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is a process method for integral solidification and molding of wing-body fusion honeycomb sandwich composite materials. The process method will be further explained in conjunction with an example of a wing-body fusion skin engineering example of a certain model.

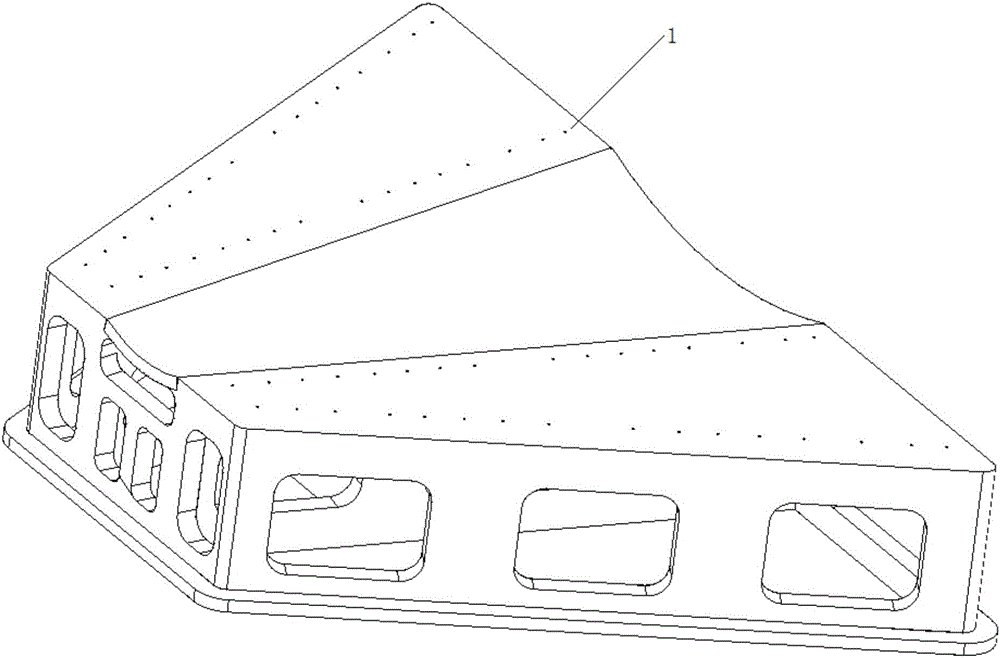

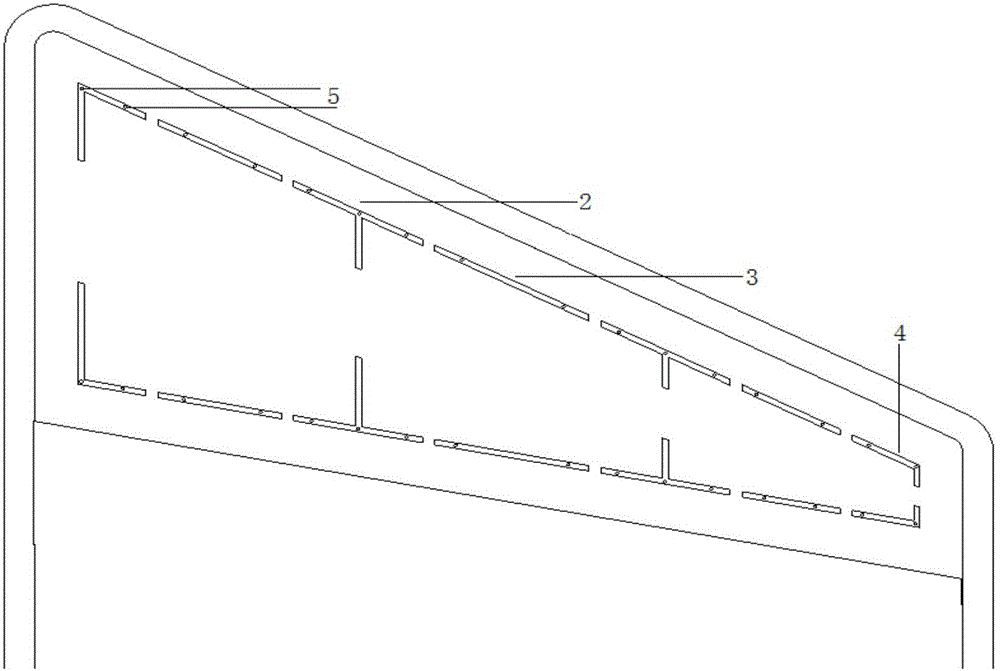

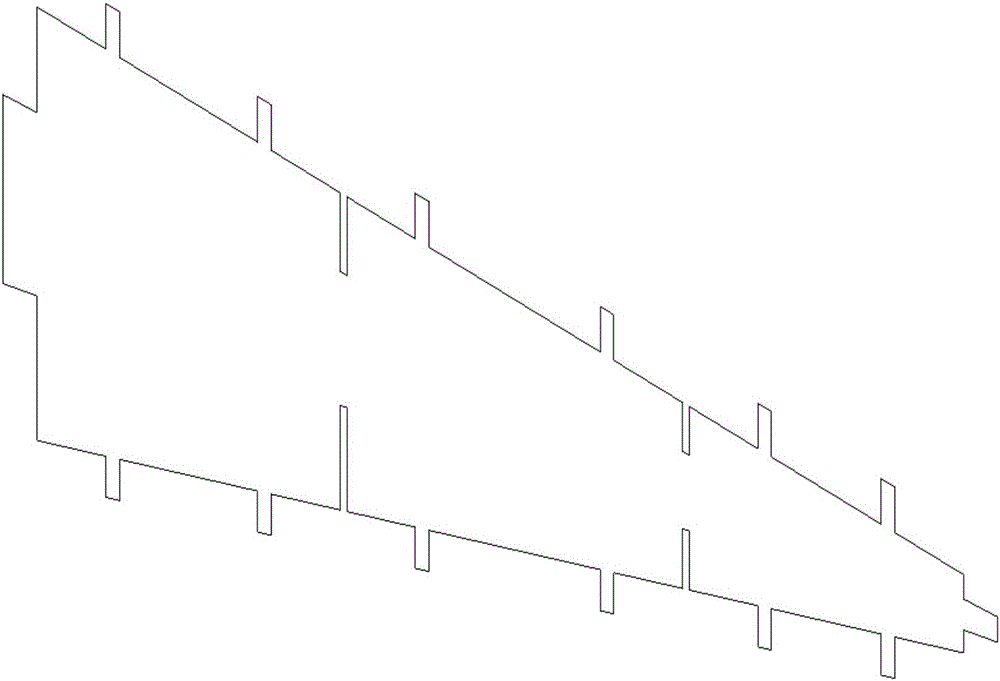

[0031] Step 1: Prepare a hot-pressing mold for the skin of the wing-body fused honeycomb sandwich composite material, and the mold includes a frame-type support structure and a mold surface. In practical engineering applications, before the hot-pressing mold is prepared, the design of the mold, the honeycomb anti-slip rib and the stiffness and strength analysis of the mold are carried out by CAD three-dimensional software and CAE finite element software: the honeycomb sandwich composite skin is designed by UG software parts mold, such as figure 1 As shown, 32 anti-slip positioning holes 1 with a diameter of 0.5 mm are designed on the mold surface. The frame structure is mainly to meet the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com