Energy-saving and low-noise spun yarn tube suitable for high-speed operation

A spun bobbin, high-speed technology, applied in the field of spun bobbins, can solve the problems of easy tube skipping, many ends breakage, affecting the yarn quality of the spinning frame, etc. The effect of poor contact accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

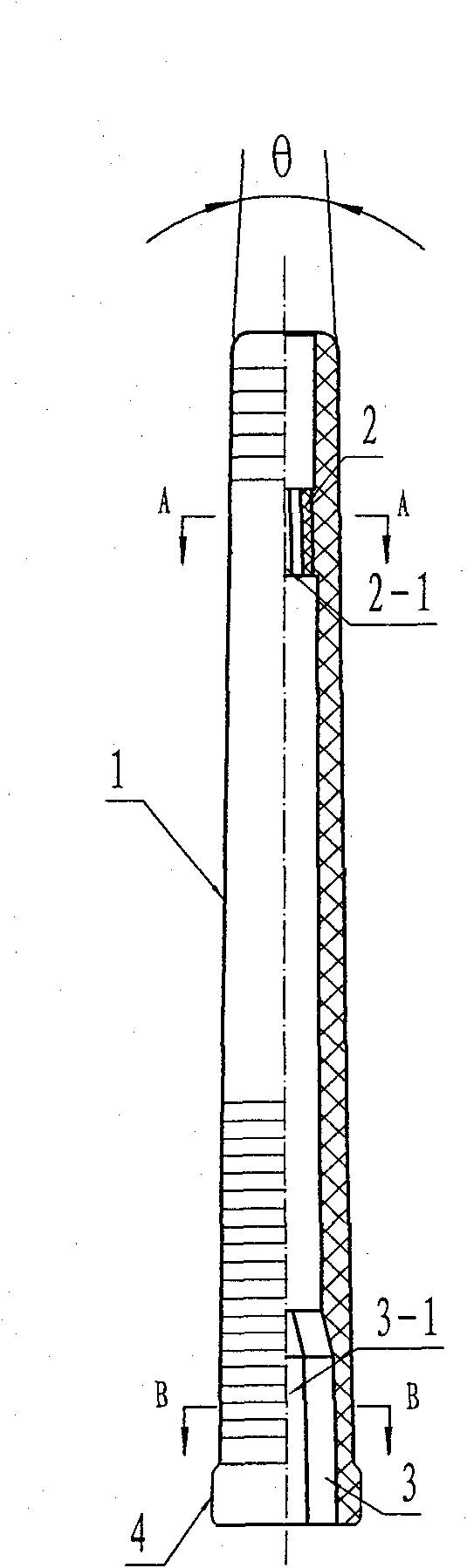

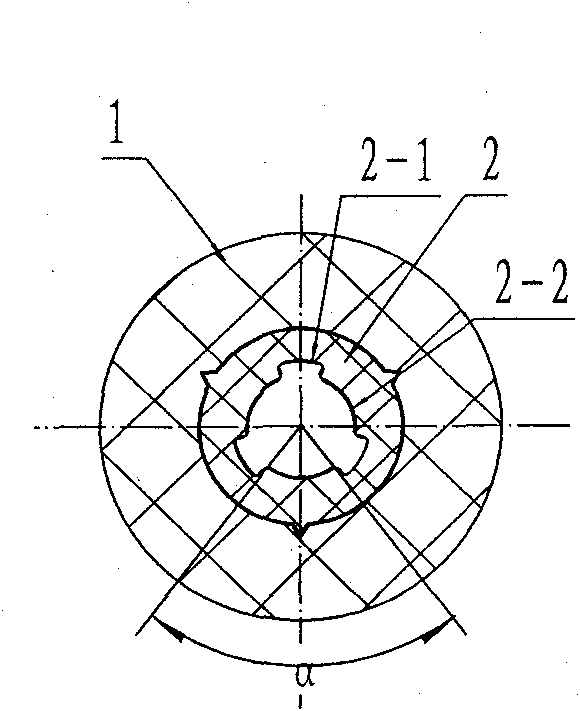

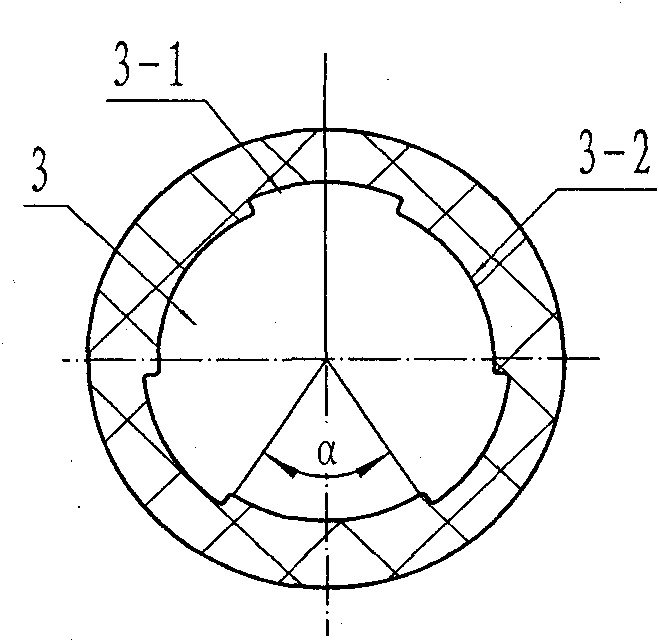

[0015] see Figure 1-3 , the present invention comprises tube body 1 and tube core 2, and tube core is positioned at the top of tube inner hole, and the inner hole of tube body bottom hole 3 and tube core 2 is the taper hole that contacts with spindle. In order to achieve energy saving, low noise, and adapt to high-speed operation, the improvement concept of the present invention is: change the joint part of the bobbin and the spindle from continuous full curved surface contact to intermittent partial curved surface contact, thereby reducing the contact area and improving the contact area. precision. The specific plan is: set uniformly distributed longitudinal grooves 3-1 at the bottom hole 3 of the pipe body, and the number of longitudinal grooves in the bottom hole of the pipe body is 3 to 6; The longitudinal groove 2-1 in the inner hole of the tube core, the number of the longitudinal grooves in the inner hole of the tube core is 3-6. The longitudinal grooves provided at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com