Hot air drawing box for high-strength high-modulus superhigh molecular weight polyethylene fibers

A polyethylene fiber, high molecular weight technology, applied in the direction of one-component polyolefin rayon, heat treatment of rayon, textile and paper making, etc. It also solves problems such as uneven distribution, and achieves the effect of fast heating speed, reduction of filaments and broken ends, and constant and uniform temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention will now be described in conjunction with the accompanying drawings.

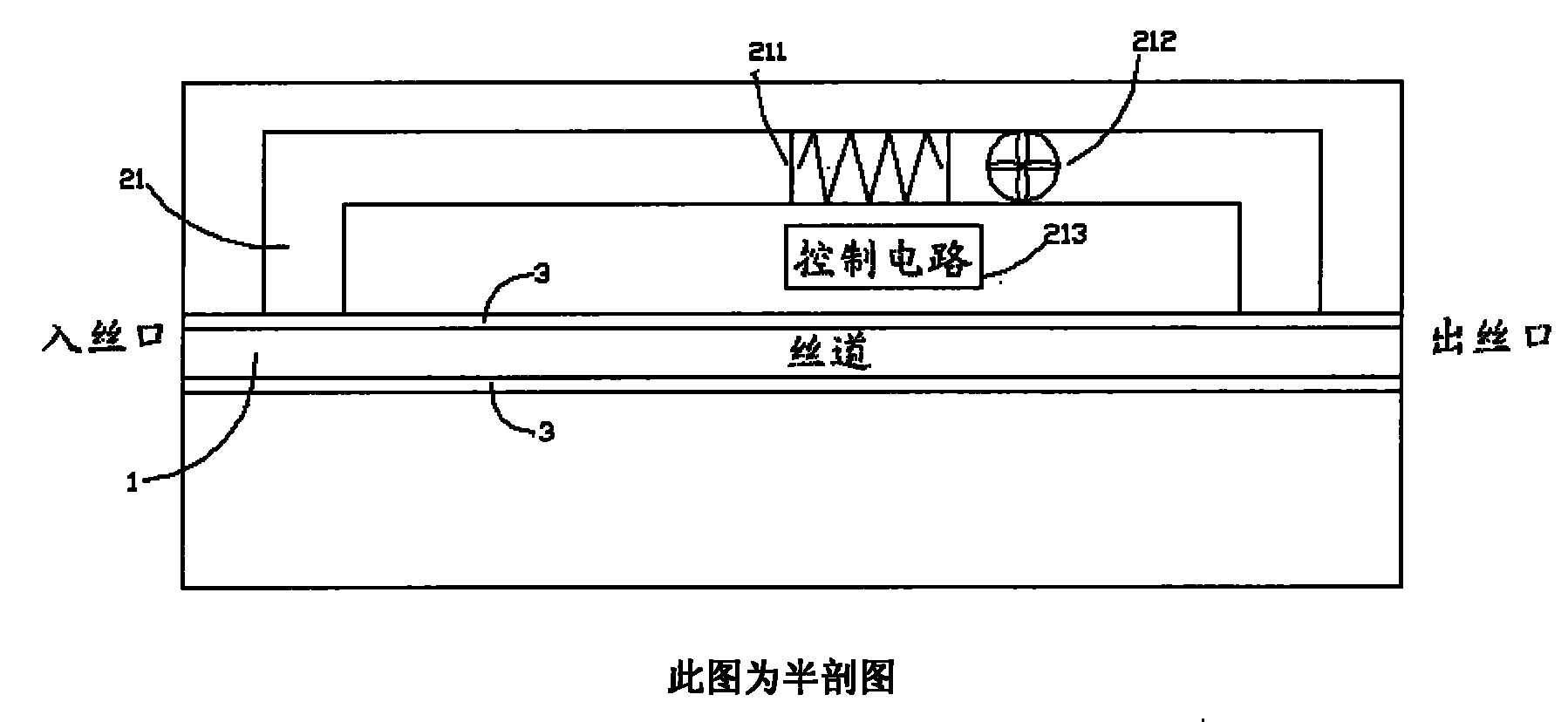

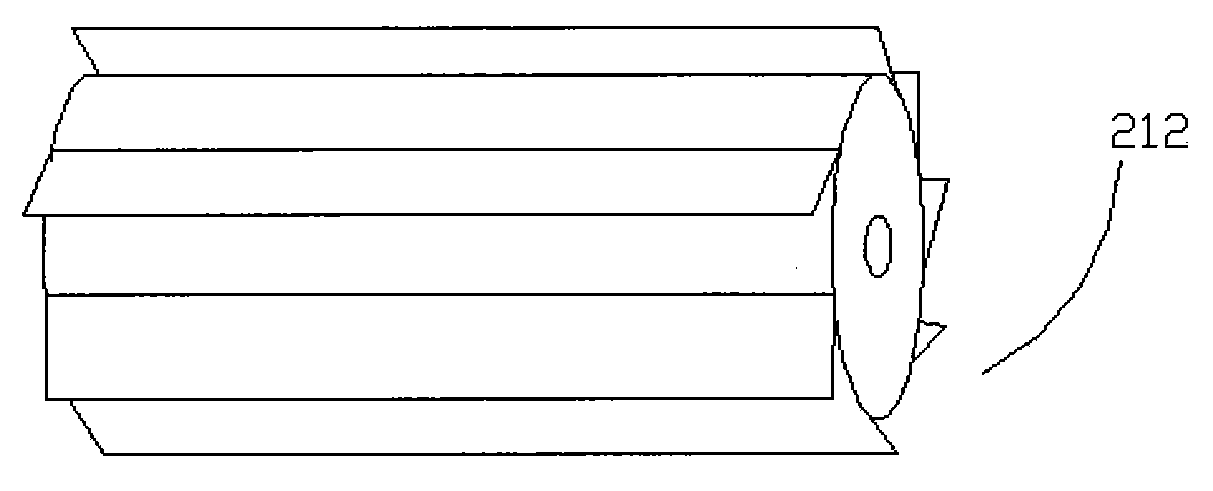

[0018] refer to figure 1 , a high-strength, high-modulus ultra-high molecular weight polyethylene fiber hot air drafting box of the present invention includes a silk path 1 and an air path 21 communicating with the thread path 1, an electric heater 211 is arranged in the air path 21, and the two ends of the thread path 1 A wire inlet and a wire outlet are provided, and each panel of the wire path 1 is provided with an electric heating film 3 connected with an electric heater 211 . The electric heating film 3 is controlled by the electric heater 211 through the control circuit 213 . Utilizing the characteristics of fast heating speed of the electric heating film, when the temperature drops in the thread path, the control circuit controls the electric heater to automatically start the electric heating film to generate heat, and heats up rapidly to com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com