Dryer system for high-strength high-modulus superhigh molecular weight polyethylene fibers

A technology of ultra-high molecular weight and polyethylene fibers, which is applied in the field of dryer systems for high-strength and high-modulus ultra-high molecular weight polyethylene fibers, which can solve problems such as inability to reuse hot air, waste energy, and affect post-stretch properties of fibers, so as to maintain stable production , Improve the stretching state, the effect of easy system pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The embodiments of the present invention will be described in detail below.

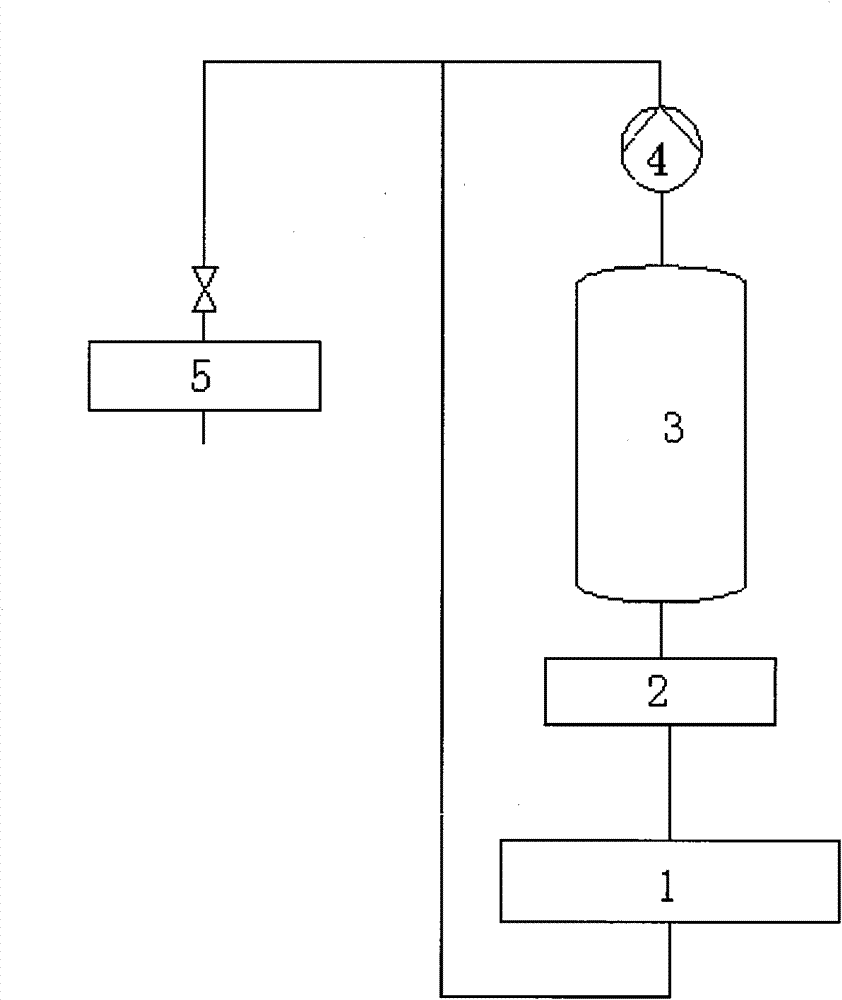

[0016] The dryer system of a high-strength, high-modulus, ultra-high molecular weight polyethylene fiber according to the present invention has a schematic structural view. figure 1 , Including mixer 1, heater 2, dryer 3, induced draft fan 4 and blower 5, said mixer 1, heater 2, dryer 3 and induced draft fan 4 are connected in turn and form a loop, said blower 5 The induced draft fan 4 and the mixer 1 are respectively connected through valves. The amount of air discharged into the blower 5 is 10%. The dryer 3 includes an active stick, and the active stick is fixed on both sides. After the air is mixed by the mixer, it enters the heater 2 for heating again, and then is introduced into the dryer 3 again by the phoenix induction machine 4 for recycling. The hot air from the induced draft fan 4 is adjusted to a discharge volume of 10% through a valve and enters the hair dryer 5. Realize the pre-dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com